7590 Hempadur Fibre 4760 brochure_REN2.indd - Net

7590 Hempadur Fibre 4760 brochure_REN2.indd - Net

7590 Hempadur Fibre 4760 brochure_REN2.indd - Net

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

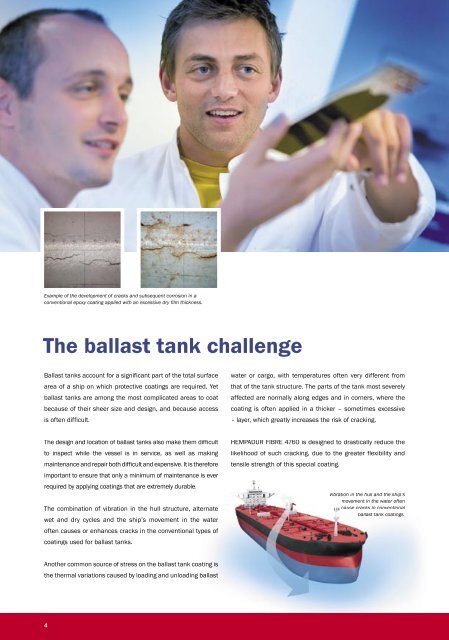

Example of the development of cracks and subsequent corrosion in a<br />

conventional epoxy coating applied with an excessive dry film thickness.<br />

The ballast tank challenge<br />

Ballast tanks account for a significant part of the total surface<br />

area of a ship on which protective coatings are required. Yet<br />

ballast tanks are among the most complicated areas to coat<br />

because of their sheer size and design, and because access<br />

is often difficult.<br />

The design and location of ballast tanks also make them difficult<br />

to inspect while the vessel is in service, as well as making<br />

maintenance and repair both difficult and expensive. It is therefore<br />

important to ensure that only a minimum of maintenance is ever<br />

required by applying coatings that are extremely durable.<br />

The combination of vibration in the hull structure, alternate<br />

wet and dry cycles and the ship’s movement in the water<br />

often causes or enhances cracks in the conventional types of<br />

coatings used for ballast tanks.<br />

Another common source of stress on the ballast tank coating is<br />

the thermal variations caused by loading and unloading ballast<br />

4<br />

water or cargo, with temperatures often very different from<br />

that of the tank structure. The parts of the tank most severely<br />

affected are normally along edges and in corners, where the<br />

coating is often applied in a thicker – sometimes excessive<br />

– layer, which greatly increases the risk of cracking.<br />

HEMPADUR FIBRE <strong>4760</strong> is designed to drastically reduce the<br />

likelihood of such cracking, due to the greater flexibility and<br />

tensile strength of this special coating.<br />

Vibration in the hull and the ship’s<br />

movement in the water often<br />

cause cracks in conventional<br />

ballast tank coatings.