Methodology for assessing carbon footprints of horticultural products

Methodology for assessing carbon footprints of horticultural products

Methodology for assessing carbon footprints of horticultural products

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

5.2 Combined heat and power (CHP) in greenhouse horticulture<br />

5.2.1 Problem description<br />

A significant proportion <strong>of</strong> Dutch greenhouse horticulture businesses produce energy as well as crops. A<br />

CHP plant produces heat, <strong>carbon</strong> dioxide and electricity from natural gas. The heat and <strong>carbon</strong> dioxide and<br />

part <strong>of</strong> the electricity are used in the greenhouse, the remaining energy (<strong>of</strong>ten in the <strong>for</strong>m <strong>of</strong> electricity) is<br />

sold. If another product besides the crop is produced, the question that arises is how the greenhouse gas<br />

emissions from the CHP unit should be allocated between the co-<strong>products</strong>.<br />

5.2.2 Review <strong>of</strong> solutions<br />

Dividing the process up into smaller processes in which no co-production occurs is not possible when a<br />

<strong>horticultural</strong> business operates a CHP unit because the production <strong>of</strong> heat and electricity by a CHP unit are<br />

inextricably linked. There are there<strong>for</strong>e two options <strong>for</strong> allocating the greenhouse gas emissions <strong>of</strong> a<br />

<strong>horticultural</strong> business between the crop and other <strong>products</strong>:<br />

1. System expansion<br />

2. Physical or economic allocation<br />

For the system expansion option we describe the PAS 2050 method and a variant <strong>of</strong> this method that is more<br />

consistent with the allocation principles we have <strong>for</strong>mulated <strong>for</strong> <strong>horticultural</strong> <strong>products</strong>. For the allocation<br />

option we describe, compare and assess three methods. In the subsequent sections we make<br />

recommendations <strong>for</strong> the protocol, the calculation tool and further research. We illustrate the various options<br />

using two example businesses: a tomato and a rose producer, both <strong>of</strong> which have a CHP unit and supply<br />

electricity to the national grid (Table 5.2). In the example calculations we include only the greenhouse gas<br />

emissions arising from the consumption and supply <strong>of</strong> electricity. The greenhouse gas emissions that are<br />

associated with materials use, fertilisation and transport make a relatively limited contribution and so we<br />

ignore these here.<br />

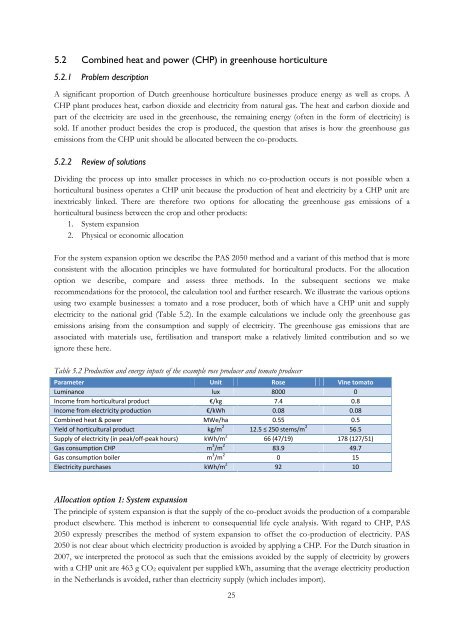

Table 5.2 Production and energy inputs <strong>of</strong> the example rose producer and tomato producer<br />

Parameter Unit Rose Vine tomato<br />

Luminance lux 8000 0<br />

Income from <strong>horticultural</strong> product €/kg 7.4 0.8<br />

Income from electricity production €/kWh 0.08 0.08<br />

Combined heat & power MWe/ha 0.55 0.5<br />

Yield <strong>of</strong> <strong>horticultural</strong> product kg/m 2 12.5 ≤ 250 stems/m 2 56.5<br />

Supply <strong>of</strong> electricity (in peak/<strong>of</strong>f-peak hours) kWh/m 2 66 (47/19) 178 (127/51)<br />

Gas consumption CHP m 3 /m 2 83.9 49.7<br />

Gas consumption boiler m 3 /m 2 0 15<br />

Electricity purchases kWh/m 2 92 10<br />

Allocation option 1: System expansion<br />

The principle <strong>of</strong> system expansion is that the supply <strong>of</strong> the co-product avoids the production <strong>of</strong> a comparable<br />

product elsewhere. This method is inherent to consequential life cycle analysis. With regard to CHP, PAS<br />

2050 expressly prescribes the method <strong>of</strong> system expansion to <strong>of</strong>fset the co-production <strong>of</strong> electricity. PAS<br />

2050 is not clear about which electricity production is avoided by applying a CHP. For the Dutch situation in<br />

2007, we interpreted the protocol as such that the emissions avoided by the supply <strong>of</strong> electricity by growers<br />

with a CHP unit are 463 g CO2 equivalent per supplied kWh, assuming that the average electricity production<br />

in the Netherlands is avoided, rather than electricity supply (which includes import).<br />

25