Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

The task of adjusting the points is a bit irksome, as it will annoy the neighbors! Basically, you turn the<br />

adjustment nut while energizing the horn with a couple of wires until a good sound comes out of the horn.<br />

After reinstalling the horns, all that was left was to install the horn button and horn ring. That job took a<br />

little bit of patience in order to make the system work reliably, as described next.<br />

To get the horn ring and button working right, I first had to adjust the longitudinal position of the steering<br />

shaft relative to the steering column. This was because I had changed this positioning inadvertently as part<br />

of the installation of a rack and pinion steering unit. This is not necessary on cars with stock steering.<br />

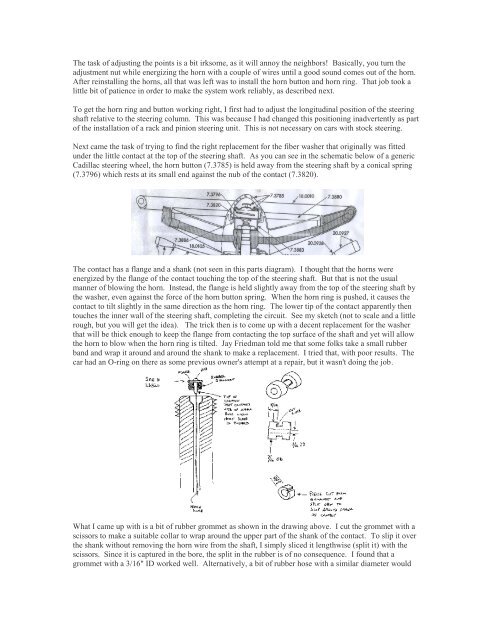

Next came the task of trying to find the right replacement for the fiber washer that originally was fitted<br />

under the little contact at the top of the steering shaft. As you can see in the schematic below of a generic<br />

Cadillac steering wheel, the horn button (7.3785) is held away from the steering shaft by a conical spring<br />

(7.3796) which rests at its small end against the nub of the contact (7.3820).<br />

The contact has a flange and a shank (not seen in this parts diagram). I thought that the horns were<br />

energized by the flange of the contact touching the top of the steering shaft. But that is not the usual<br />

manner of blowing the horn. Instead, the flange is held slightly away from the top of the steering shaft by<br />

the washer, even against the force of the horn button spring. When the horn ring is pushed, it causes the<br />

contact to tilt slightly in the same direction as the horn ring. The lower tip of the contact apparently then<br />

touches the inner wall of the steering shaft, completing the circuit. See my sketch (not to scale and a little<br />

rough, but you will get the idea). The trick then is to come up with a decent replacement for the washer<br />

that will be thick enough to keep the flange from contacting the top surface of the shaft and yet will allow<br />

the horn to blow when the horn ring is tilted. Jay Friedman told me that some folks take a small rubber<br />

band and wrap it around and around the shank to make a replacement. I tried that, with poor results. The<br />

car had an O-ring on there as some previous owner's attempt at a repair, but it wasn't doing the job.<br />

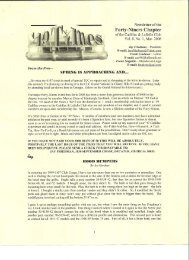

What I came up with is a bit of rubber grommet as shown in the drawing above. I cut the grommet with a<br />

scissors to make a suitable collar to wrap around the upper part of the shank of the contact. To slip it over<br />

the shank without removing the horn wire from the shaft, I simply sliced it lengthwise (split it) with the<br />

scissors. Since it is captured in the bore, the split in the rubber is of no consequence. I found that a<br />

grommet with a 3/16" ID worked well. Alternatively, a bit of rubber hose with a similar diameter would