By: Dr. M.S. Parmar, M. Singh and Neha NITRA - Fibre2fashion

By: Dr. M.S. Parmar, M. Singh and Neha NITRA - Fibre2fashion

By: Dr. M.S. Parmar, M. Singh and Neha NITRA - Fibre2fashion

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

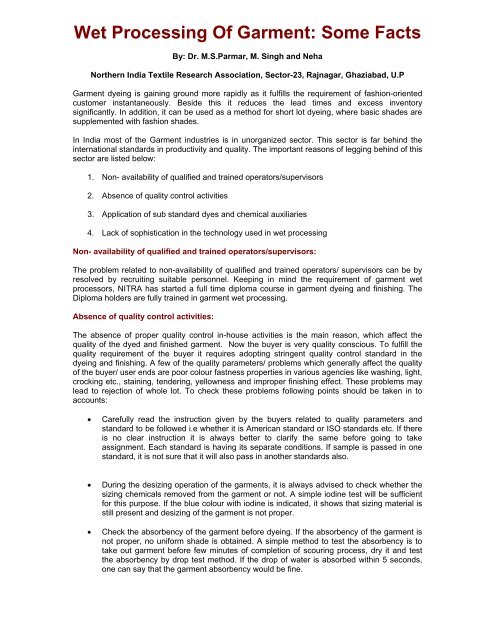

Wet Processing Of Garment: Some Facts<br />

<strong>By</strong>: <strong>Dr</strong>. M.S.<strong>Parmar</strong>, M. <strong>Singh</strong> <strong>and</strong> <strong>Neha</strong><br />

Northern India Textile Research Association, Sector-23, Rajnagar, Ghaziabad, U.P<br />

Garment dyeing is gaining ground more rapidly as it fulfills the requirement of fashion-oriented<br />

customer instantaneously. Beside this it reduces the lead times <strong>and</strong> excess inventory<br />

significantly. In addition, it can be used as a method for short lot dyeing, where basic shades are<br />

supplemented with fashion shades.<br />

In India most of the Garment industries is in unorganized sector. This sector is far behind the<br />

international st<strong>and</strong>ards in productivity <strong>and</strong> quality. The important reasons of legging behind of this<br />

sector are listed below:<br />

1. Non- availability of qualified <strong>and</strong> trained operators/supervisors<br />

2. Absence of quality control activities<br />

3. Application of sub st<strong>and</strong>ard dyes <strong>and</strong> chemical auxiliaries<br />

4. Lack of sophistication in the technology used in wet processing<br />

Non- availability of qualified <strong>and</strong> trained operators/supervisors:<br />

The problem related to non-availability of qualified <strong>and</strong> trained operators/ supervisors can be by<br />

resolved by recruiting suitable personnel. Keeping in mind the requirement of garment wet<br />

processors, <strong>NITRA</strong> has started a full time diploma course in garment dyeing <strong>and</strong> finishing. The<br />

Diploma holders are fully trained in garment wet processing.<br />

Absence of quality control activities:<br />

The absence of proper quality control in-house activities is the main reason, which affect the<br />

quality of the dyed <strong>and</strong> finished garment. Now the buyer is very quality conscious. To fulfill the<br />

quality requirement of the buyer it requires adopting stringent quality control st<strong>and</strong>ard in the<br />

dyeing <strong>and</strong> finishing. A few of the quality parameters/ problems which generally affect the quality<br />

of the buyer/ user ends are poor colour fastness properties in various agencies like washing, light,<br />

crocking etc., staining, tendering, yellowness <strong>and</strong> improper finishing effect. These problems may<br />

lead to rejection of whole lot. To check these problems following points should be taken in to<br />

accounts:<br />

• Carefully read the instruction given by the buyers related to quality parameters <strong>and</strong><br />

st<strong>and</strong>ard to be followed i.e whether it is American st<strong>and</strong>ard or ISO st<strong>and</strong>ards etc. If there<br />

is no clear instruction it is always better to clarify the same before going to take<br />

assignment. Each st<strong>and</strong>ard is having its separate conditions. If sample is passed in one<br />

st<strong>and</strong>ard, it is not sure that it will also pass in another st<strong>and</strong>ards also.<br />

• During the desizing operation of the garments, it is always advised to check whether the<br />

sizing chemicals removed from the garment or not. A simple iodine test will be sufficient<br />

for this purpose. If the blue colour with iodine is indicated, it shows that sizing material is<br />

still present <strong>and</strong> desizing of the garment is not proper.<br />

• Check the absorbency of the garment before dyeing. If the absorbency of the garment is<br />

not proper, no uniform shade is obtained. A simple method to test the absorbency is to<br />

take out garment before few minutes of completion of scouring process, dry it <strong>and</strong> test<br />

the absorbency by drop test method. If the drop of water is absorbed within 5 seconds,<br />

one can say that the garment absorbency would be fine.