Effective and Productive Instrument Processing - Friends of Hu-Friedy

Effective and Productive Instrument Processing - Friends of Hu-Friedy

Effective and Productive Instrument Processing - Friends of Hu-Friedy

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

<strong>Effective</strong> <strong>and</strong> <strong>Productive</strong><br />

<strong>Instrument</strong> <strong>Processing</strong><br />

A Peer-Reviewed Publication<br />

Written by Noel Br<strong>and</strong>on Kelsch, RDHAP<br />

Earn<br />

4 CE credits<br />

This course was<br />

written for dentists,<br />

dental hygienists,<br />

<strong>and</strong> assistants.<br />

Go Green, Go Online to take your course<br />

This course has been made possible through an unrestricted educational grant. The cost <strong>of</strong> this CE course is $59.00 for 4 CE credits.<br />

Cancellation/Refund Policy: Any participant who is not 100% satisfied with this course can request a full refund by contacting PennWell in writing.

Educational Objectives<br />

The overall goal <strong>of</strong> this course is to provide information on infection control<br />

in the dental <strong>of</strong>fice. Upon completion <strong>of</strong> this course, the clinician will<br />

be able to do the following:<br />

1. Describe the chain <strong>of</strong> infection <strong>and</strong> modes <strong>of</strong> transmission <strong>of</strong><br />

microorganisms in the dental <strong>of</strong>fice.<br />

2. Know <strong>and</strong> underst<strong>and</strong> the four basic principles <strong>and</strong> goals to reduce<br />

microbial transmission.<br />

3. Know which instruments must be sterilized, the methods by which<br />

this can be achieved, <strong>and</strong> the role <strong>and</strong> importance <strong>of</strong> external <strong>and</strong><br />

internal indicators on packaging.<br />

4. Underst<strong>and</strong> instrument processing steps <strong>and</strong> the use <strong>of</strong> instrument<br />

management systems in this process.<br />

Abstract<br />

In order to meet the challenges <strong>of</strong> safety, time management <strong>and</strong> asepsis,<br />

the dental health care provider must have a plan for infection control,<br />

including the use <strong>and</strong> care <strong>of</strong> dental instruments <strong>and</strong> disposables. Following<br />

the basic CDC guidelines can help to significantly reduce the risk <strong>of</strong><br />

microbial transmission. After the patient is dismissed, the operatory must<br />

be prepared for the next patient, including the treatment <strong>of</strong> surfaces <strong>and</strong><br />

instrument processing. There is a variety <strong>of</strong> methods available to properly<br />

reprocess instruments. Choosing a system that minimizes risk, maximizes<br />

productivity <strong>and</strong> preserves instruments is essential.<br />

Introduction<br />

One <strong>of</strong> the most stressful times in dentistry can be the result <strong>of</strong> a<br />

single missing, damaged or nonsterile instrument. In order to meet<br />

the challenges <strong>of</strong> safety, time management <strong>and</strong> asepsis, the dental<br />

health care provider (DHCP) must have a plan for infection control,<br />

including the use <strong>and</strong> care <strong>of</strong> dental instruments. The plan must<br />

meet the guidelines <strong>of</strong> the Occupational Safety <strong>and</strong> Health Administration<br />

(OSHA) <strong>and</strong> the Centers for Disease Control (CDC).<br />

The chain <strong>of</strong> infection<br />

In order for a disease to occur, a number <strong>of</strong> conditions must exist.<br />

These conditions, called the chain <strong>of</strong> infection, are:<br />

1. An appropriate portal <strong>of</strong> entry for a pathogen into a new host<br />

2. A person who is not immune to the pathogen<br />

3. A pathogen in sufficient numbers to cause infection<br />

4. A place for the pathogen to reside <strong>and</strong> multiply<br />

5. A way for the pathogen to leave its reservoir <strong>and</strong> reach the<br />

new host<br />

All five conditions must be present for disease to occur. 1<br />

Modes <strong>of</strong> transmission<br />

During <strong>and</strong> following dental treatment, diseases can be transmitted<br />

between:<br />

• Patient <strong>and</strong> dental staff • Dental staff <strong>and</strong> patient<br />

• Patient <strong>and</strong> patient • Dental staff <strong>and</strong> dental staff<br />

In general, it is more likely that diseases would be transmitted<br />

from patients to clinicians than vice versa, because clinicians have<br />

frequent contact with patients’ saliva <strong>and</strong> blood during dental<br />

procedures.<br />

Occupational Exposure<br />

Exposure <strong>of</strong> DHCPs <strong>and</strong> patients to pathogenic microorganisms<br />

can result from transmission through:<br />

• Direct contact with blood, oral fluids, or other patient tissues<br />

• Direct contact <strong>of</strong> intact or nonintact skin with blood, oral<br />

fluids or other potentially infectious patient materials<br />

• Contact <strong>of</strong> conjunctival, nasal or oral mucosa with droplets<br />

(spray or spatter) containing microorganisms generated from<br />

an infected person <strong>and</strong> propelled a short distance (e.g., by<br />

coughing, sneezing or talking)<br />

• Inhalation <strong>of</strong> airborne microorganisms that can remain<br />

suspended in the air for long periods 1<br />

• Indirect contact with contaminated objects (e.g., instruments,<br />

equipment or environmental surfaces)<br />

Cross-contamination <strong>and</strong> Cross-infection<br />

During treatment, areas <strong>of</strong> the operatory can become contaminated<br />

with pathogens from blood, saliva <strong>and</strong> other body fluids. For<br />

example, when working with equipment such as ultrasonic scalers<br />

<strong>and</strong> high-speed h<strong>and</strong>pieces, aerosols are created that can l<strong>and</strong> on<br />

environmental surfaces. When the DHCP touches those surfaces,<br />

the microorganisms can be transferred to his or her h<strong>and</strong>s. If the<br />

DHCP does not wash his or her h<strong>and</strong>s <strong>and</strong> then touches his or her<br />

eyes, mouth or nose, the microorganisms can enter the provider as<br />

a host. If the DHCP greets a patient <strong>and</strong> shakes his or her h<strong>and</strong>,<br />

transfer <strong>of</strong> the bacteria or virus to the patient can also occur. This<br />

process, called cross-contamination or cross-infection, can place<br />

the DHCP <strong>and</strong> patients at risk. 2,3<br />

Limiting Exposure through Infection Control<br />

Although a DHCP’s work may increase the risk <strong>of</strong> infection, a<br />

number <strong>of</strong> procedures used routinely in dental settings help keep<br />

that risk to a minimum.<br />

Table 1. The Four Basic Principles<br />

Keep yourself healthy. This has a major impact on disease transmission.<br />

It emphasizes the need for dental personnel to be protected<br />

through immunizations, work restrictions <strong>and</strong> regular h<strong>and</strong> hygiene.<br />

Avoid contact with blood <strong>and</strong> body fluids. This focuses on the use <strong>of</strong><br />

st<strong>and</strong>ard precautions, engineering controls <strong>and</strong> work practice controls.<br />

This principle also emphasizes the use <strong>of</strong> personal protection equipment<br />

(PPE) to prevent bloodborne exposure, as well as the management <strong>of</strong><br />

postexposure incidents.<br />

Limit contamination. This involves conducting general housekeeping,<br />

covering <strong>and</strong> disinfecting environmental surfaces, minimizing sprays <strong>and</strong><br />

splashes, properly disposing <strong>of</strong> medical waste, <strong>and</strong> maintaining water<br />

quality in dental unit waterlines. 4<br />

Make objects safe for use. Single-use items <strong>and</strong> thorough cleaning<br />

<strong>and</strong> sterilization <strong>of</strong> patient care items help in this area. Using instrument<br />

management systems can help minimize h<strong>and</strong>ling, sharps injuries <strong>and</strong><br />

exposure. Simply placing an instrument setup into a cassette limits DHCP<br />

exposure to sharps <strong>and</strong> contaminated instruments <strong>and</strong> allows for a more<br />

automated cleaning process.<br />

Infection control refers to the basic principles <strong>and</strong> series <strong>of</strong> steps<br />

that help prevent disease transmission. Following the basic<br />

guidelines that the CDC has provided can help to significantly<br />

2 www.ineedce.com

educe the risk <strong>of</strong> microbial transmission in the dental setting.<br />

The goal <strong>of</strong> each <strong>of</strong> the four basic principles is to break one or<br />

more links in the chain <strong>of</strong> infection. 5<br />

St<strong>and</strong>ard precautions<br />

Universal precautions were created in the 1980s to help protect<br />

against bloodborne disease transmission. In dentistry, these include<br />

h<strong>and</strong> washing; use <strong>of</strong> PPE such as gloves, eyewear <strong>and</strong> face<br />

protection; <strong>and</strong> recommendations for proper h<strong>and</strong>ling <strong>of</strong> patient<br />

care items <strong>and</strong> contaminated surfaces. As the word “universal”<br />

suggests, the precautions are applied when treating all patients, regardless<br />

<strong>of</strong> health history or presumed risk <strong>of</strong> bloodborne disease.<br />

In the mid-1990s, the term “st<strong>and</strong>ard precautions” was introduced.<br />

While universal precautions focus mainly on preventing<br />

exposure to blood, st<strong>and</strong>ard precautions guard against exposure to<br />

all body fluids (except sweat, which is not considered infectious). 6<br />

In the dental setting, there is little practical difference between<br />

universal <strong>and</strong> st<strong>and</strong>ard precautions. All <strong>of</strong> the precautions traditionally<br />

used to protect against blood <strong>and</strong> blood-contaminated<br />

saliva also protect against exposure to any other fluids that would<br />

typically be encountered in the dental setting. The DHCP should<br />

treat every patient as if he or she could be a source <strong>of</strong> infection.<br />

Using st<strong>and</strong>ard precautions limits cross-contamination <strong>and</strong><br />

cross-infection. 7,8 Single-use surface barriers such as plastic wrap or<br />

sheaths prevent contamination <strong>of</strong> surfaces. 9 These barriers should<br />

be used on as many surfaces as possible, <strong>and</strong> especially on surfaces<br />

that are difficult to access or disinfect (such as X-ray tubes). The<br />

use <strong>of</strong> barriers is reliable, saves time <strong>and</strong> reduces exposure to<br />

chemicals. 10 Clinical contact surfaces that do not have barrier covers<br />

or become contaminated during removal <strong>of</strong> the barrier require<br />

surface disinfection. Disinfection should be carried out using an<br />

EPA-registered disinfectant with tuberculocidal activity (i.e.,<br />

CDC intermediate-level disinfectant) or a low-level disinfectant.<br />

Personnel <strong>and</strong> patients rarely come in contact with housekeeping<br />

surfaces. These require regular cleaning to remove soil <strong>and</strong> dust.<br />

These areas include floors, walls <strong>and</strong> some countertops. Cleaning<br />

should include use <strong>of</strong> an EPA-registered hospital disinfectant with<br />

no tuberculocidal activity (i.e., CDC low-level disinfectant) or an<br />

intermediate-level disinfectant if blood is visible.<br />

Figure 1. Disinfection <strong>of</strong> Surfaces<br />

Surface<br />

Type<br />

Clinical contact<br />

surfaces<br />

Housekeeping<br />

surfaces<br />

Single-use<br />

barrier covers<br />

CDC intermediate-level<br />

or low-level disinfectant<br />

No blood present<br />

Blood present<br />

+ disinfectant if surface<br />

contaminated<br />

CDC low-level<br />

disinfectant<br />

CDC intermediate-level<br />

disinfectant<br />

In summary, with vaccination; appropriate h<strong>and</strong> hygiene; careful<br />

h<strong>and</strong>ling <strong>of</strong> sharp items; use <strong>of</strong> barrier techniques; <strong>and</strong> proper<br />

cleaning, disinfection <strong>and</strong> sterilization procedures, you can meet<br />

many requirements for a safe workplace. <strong>Instrument</strong> processing<br />

is a key component <strong>and</strong>, when performed appropriately, breaks<br />

the chain <strong>of</strong> infection, reduces DHCP stress, improves productivity<br />

<strong>and</strong> staff safety, <strong>and</strong> results in cost savings.<br />

<strong>Instrument</strong> <strong>Processing</strong> <strong>and</strong> Infection Control<br />

After the patient is dismissed, the operatory must be prepared<br />

for the next patient, including the treatment <strong>of</strong> surfaces <strong>and</strong><br />

instrument processing. This process must be performed correctly<br />

every time to ensure items are properly processed. Having<br />

working, organized, sharp, debris-free <strong>and</strong> sterile (or disposable)<br />

instruments aids in the <strong>of</strong>fice’s production, the quality <strong>of</strong><br />

dentistry, <strong>and</strong> the safety <strong>of</strong> patients <strong>and</strong> staff. Quality sterile<br />

dental instruments are key to the practice <strong>of</strong> dentistry. Choosing<br />

a system that minimizes risk, maximizes productivity <strong>and</strong> saves<br />

money is important. In addition, while some instruments must<br />

be disposable, limiting the disposal <strong>of</strong> reusable devices helps<br />

keep the world greener. Using instrument cassettes minimizes<br />

DHCP contact with contaminated instruments, organizes the<br />

instruments for safe <strong>and</strong> efficient processing, keeps the instruments<br />

free from debris, protects instruments from damage <strong>and</strong><br />

helps instruments remain sterile after processing. Sterilization<br />

cassettes also st<strong>and</strong>ardize procedural setups by organizing the<br />

instruments by procedure or type <strong>of</strong> user. This st<strong>and</strong>ardization<br />

enables any staff member to quickly identify the proper cassette<br />

for every procedure. Cassettes help eliminate lost instruments<br />

during instrument processing or transportation to <strong>and</strong> from the<br />

operatory. Dr. Lou Graham found that by creating st<strong>and</strong>ardized<br />

setups <strong>and</strong> using the cassette system in his <strong>of</strong>fice, his staff saved<br />

an average <strong>of</strong> five minutes per procedure, which allowed the staff<br />

to spend more time with patients <strong>and</strong> contributed to productivity<br />

<strong>and</strong> therefore revenue generation. 11 <strong>Instrument</strong> processing<br />

requires consideration <strong>of</strong> the necessary equipment, workflow <strong>and</strong><br />

stages involved. In general, the processing can be divided into a<br />

chairside component <strong>and</strong> a processing area component.<br />

Having organized, sharp, <strong>and</strong> sterile (or disposable) instruments<br />

aids in production, the quality <strong>of</strong> dentistry, <strong>and</strong> safety.<br />

Chairside Procedure<br />

Single-use disposable instruments<br />

These are designed to be used only once - for one patient <strong>and</strong><br />

discarded appropriately. They cannot be cleaned, disinfected<br />

or sterilized. These include blades, needles, prophylaxis angles,<br />

carpules, cups <strong>and</strong> brushes, evacuator tips, saliva ejectors, <strong>and</strong><br />

air/water syringe tips. 3 These items are becoming more <strong>and</strong><br />

more available <strong>and</strong> economical. They eliminate the chance <strong>of</strong><br />

cross-contamination, the need for extensive postoperative h<strong>and</strong>ling<br />

(with a risk <strong>of</strong> sharps injuries) <strong>and</strong> exposure to sterilization<br />

chemicals. Disposing <strong>of</strong> all single-use items immediately after<br />

treatment limits the risk <strong>of</strong> sharps injuries.<br />

The CDC recommends that there be a sharps container in every<br />

room in which treatment is delivered. Placing sharps in the<br />

container as soon as possible eliminates the hazard quickly.<br />

www.ineedce.com 3

Disposal <strong>of</strong> sharps <strong>and</strong> prevention <strong>of</strong> sharps injuries<br />

Disposing <strong>of</strong> sharps is one <strong>of</strong> the riskiest tasks in dentistry. 9,12,13 All<br />

operatories that include use <strong>of</strong> disposable sharps (needles, blades,<br />

wires, etc.) should have a sharps container in the room. 5 All sharps<br />

should be removed from the tray <strong>and</strong> disposed <strong>of</strong> as soon as treatment<br />

is completed to decrease the risk <strong>of</strong> a sharps injury.<br />

Figure 2. Sharps Container<br />

One available device melts down <strong>and</strong> compresses used needles,<br />

needle sheaths <strong>and</strong> red bag waste into a disposable block (Demolizer<br />

II, BMTS). It is approved in most states <strong>and</strong> meets EPA <strong>and</strong><br />

OSHA requirements. While not reducing the risk <strong>of</strong> sharps injuries<br />

during the removal <strong>of</strong> sharps, it <strong>of</strong>fers a disposal alternative.<br />

Figure 3. Demolizer<br />

Disposal <strong>of</strong> non-sharps patient care items<br />

It is important to contact your area waste management system<br />

to see if they allow empty carpules to go out with the general<br />

trash. Regulations vary by state for the disposal <strong>of</strong> intact, broken,<br />

blood-filled <strong>and</strong> empty carpules. Most disposable items can go<br />

out with the general trash. The exception is cotton materials that<br />

are soaked with blood to the point that blood can be wrung out<br />

<strong>of</strong> them. Clearing the tray <strong>of</strong> all non-sharp disposables early on<br />

will give the DHCP a clear view <strong>of</strong> sharps <strong>and</strong> instruments <strong>and</strong><br />

decrease the likelihood <strong>of</strong> injury. 6<br />

The <strong>Instrument</strong> <strong>Processing</strong> Area<br />

The flow, layout <strong>and</strong> appropriate use <strong>of</strong> the instrument processing<br />

area are determining factors in successful sterilization. Office<br />

policy should include the use <strong>of</strong> puncture- <strong>and</strong> chemical-resistant<br />

utility gloves by DHCPs when cleaning dental instruments <strong>and</strong><br />

working with chemicals. Latex gloves are not puncture-resistant<br />

<strong>and</strong> can break down in the presence <strong>of</strong> chemicals. OSHA guidelines<br />

specifically state, “The person h<strong>and</strong>ling the instruments<br />

through removal, cleaning, packaging <strong>and</strong> sterilization needs to<br />

use heavy-duty gloves to help prevent injury with sharp contaminated<br />

instruments.” Many DHCPs complain that heavy-duty<br />

gloves do not have the same tactile sensitivity as examination<br />

gloves. However, the fine tactile sensitivity that is needed during<br />

dental procedures is not necessary during instrument cleaning<br />

<strong>and</strong> sterilization. Additionally, some utility gloves come sized to<br />

meet your individual needs.<br />

Figure 4. Use <strong>of</strong> Utility Gloves<br />

The DHCP must wear proper protective equipment, including<br />

utility gloves, mask, glasses, <strong>and</strong> clinic gown or jacket, during<br />

instrument processing. Properly fitting masks, protective eye wear<br />

<strong>and</strong> a full gown must also be utilized to avoid contact with splashes,<br />

sprays <strong>and</strong> aerosols that are present in the sterilization area. The<br />

instrument processing area should be separated into four specific<br />

areas as far apart as possible <strong>and</strong> with clearly defined “clean” <strong>and</strong><br />

“dirty” areas. The separate areas involved in instrument processing<br />

are as follows:<br />

Receiving, Cleaning <strong>and</strong> Decontamination<br />

Cassettes <strong>and</strong> instruments are placed here for removal <strong>of</strong> debris<br />

before processing. This area should be clearly defined to prevent<br />

cross-contamination. It is recommended that instrument h<strong>and</strong>ling<br />

be minimized, as this is where a high percentage <strong>of</strong> sharps<br />

injuries occur. Specific containers are also available for syringes,<br />

burs <strong>and</strong> other instruments. H<strong>and</strong>pieces must be heat-sterilized<br />

(autoclaved) after single patient use, <strong>and</strong> it is important to follow<br />

the manufacturer’s instructions on cleaning, lubrication <strong>and</strong><br />

sterilizing h<strong>and</strong>pieces to ensure proper sterilization <strong>and</strong> to avoid<br />

h<strong>and</strong>piece damage.<br />

Preparation <strong>and</strong> Packaging<br />

This area must have enough space for safe packaging <strong>and</strong> preparation.<br />

Supplies should be readily available to eliminate the chance<br />

<strong>of</strong> contaminating drawer h<strong>and</strong>les <strong>and</strong> cupboards. Before preparing<br />

<strong>and</strong> packaging, all instruments <strong>and</strong> other patient care items should<br />

be inspected for cleanliness <strong>and</strong> completely dried.<br />

4 www.ineedce.com

Sterilization<br />

This is the most important area in the process. Contaminated<br />

items go into the sterilizer. If the sterilizer is working properly<br />

<strong>and</strong> the appropriate process is followed, instruments <strong>and</strong> other<br />

patient care items will be sterile. To prevent contamination <strong>of</strong><br />

the front <strong>and</strong> h<strong>and</strong>les <strong>of</strong> the sterilizer during the loading process,<br />

simply open the sterilizer door with a paper towel.<br />

Tips for <strong>Instrument</strong> <strong>Processing</strong> Areas<br />

• Every DHCP should have a personal set <strong>of</strong> heavy-duty utility gloves,<br />

disinfected <strong>and</strong> evaluated for cracks <strong>and</strong> integrity daily. This will help<br />

with compliance <strong>and</strong> guard against sharps injuries.<br />

• To prevent having to change gloves, keep a spare set <strong>of</strong> clean cotton<br />

forceps or a set <strong>of</strong> tongs to open <strong>and</strong> take things out <strong>of</strong> drawers <strong>and</strong><br />

cupboards.<br />

• Keep sterilization pouches in an open, easy-to-access location to<br />

eliminate the risk <strong>of</strong> cross-contamination from opening drawers <strong>and</strong><br />

cupboards.<br />

• Having the sterilizer divide the room between clean <strong>and</strong> dirty (one<br />

side is the dirty side, one side is the clean side) is a simple way to help<br />

everyone underst<strong>and</strong> the concept.<br />

• An instrument management system that includes procedure tubs <strong>and</strong><br />

cassettes is the most efficient <strong>and</strong> organized way to manage instruments<br />

<strong>and</strong> consumable products, <strong>and</strong> saves time.<br />

• Procedure tubs <strong>and</strong> cassettes limit exposure to pathogens <strong>and</strong> sharps<br />

injuries.<br />

Storage<br />

The storage <strong>of</strong> instruments <strong>and</strong> cassettes following sterilization<br />

should preserve the integrity <strong>of</strong> the packaging material. Sterilized<br />

items should be stored in a clean, dry environment away from<br />

areas where contaminated instruments are present. Do not store<br />

instruments or supplies under sinks, over sterilization devices,<br />

or in areas where moisture or environmental factors could contaminate<br />

the packaging. To optimize organization <strong>of</strong> supplies,<br />

keeping tubs for supplies in a central location is ideal. Having<br />

a separate tub for different procedures saves time searching for<br />

<strong>and</strong> gathering supplies <strong>and</strong> maximizes use <strong>of</strong> materials. A simple<br />

inventory list accompanying each tub will help all staff maintain<br />

the system easily. These tubs can act as portable operatory drawers<br />

for storing, organizing <strong>and</strong> transporting consumable materials<br />

to <strong>and</strong> from storage, the sterilization area <strong>and</strong> the operatory.<br />

Figure 5. Organization <strong>of</strong> Consumable Materials in Tubs<br />

<strong>Instrument</strong> <strong>Processing</strong> <strong>of</strong> Non-disposable Items<br />

<strong>Hu</strong>man error is the most common reason for failure. The instrument<br />

management process must be followed appropriately<br />

every time.<br />

Divide <strong>and</strong> conquer<br />

Before processing instruments, it is important to divide them into<br />

categories <strong>of</strong> use. Critical instruments are surgical <strong>and</strong> other instruments<br />

used to penetrate the mucosa <strong>and</strong> bone. This category includes<br />

bone chisels, scalers <strong>and</strong> burs. Critical instruments require<br />

heat sterilization or must be single-use disposable. Sterilization is<br />

achieved by steam under pressure (autoclaving), dry heat or heat/<br />

chemical sterilization. Semi-critical instruments are surgical <strong>and</strong><br />

other instruments that are not used to penetrate s<strong>of</strong>t tissue or bone,<br />

but come in contact with the oral tissue. These require heat sterilization<br />

or, if an item is heat sensitive, immersion in a high-level<br />

disinfectant/sterilant. A high-level disinfectant registered with<br />

the EPA as a sterilant/disinfectant must be clearly labeled as such.<br />

Noncritical instruments are instruments that only come in contact<br />

with intact skin. They do not come in contact with mucosa. These<br />

can be sterilized by immersing them in a high-level disinfectant<br />

or can be processed with an intermediate-level disinfectant. Such<br />

devices have a relatively low risk <strong>of</strong> transmitting infection. An<br />

intermediate-level disinfectant will be labeled as a hospital disinfectant<br />

<strong>and</strong> also for tuberculocidal activity (exemplified by phenolics,<br />

iodophors <strong>and</strong> chlorine-based compounds). 14<br />

Transporting instruments<br />

Once all disposables <strong>and</strong> sharps are removed from the counter or<br />

chair tray <strong>and</strong> placed in the proper receptacles, all instruments<br />

should be kept in cassettes to limit h<strong>and</strong>ling <strong>and</strong> decrease the risk<br />

<strong>of</strong> sharps injury. Using instrument cassettes <strong>and</strong> sorting devices<br />

can make all the difference in the preparation <strong>and</strong> packaging area.<br />

Cassettes not only hold the instruments securely during cleaning<br />

<strong>and</strong> sterilization, but they also limit dulling, instrument loss,<br />

sharps injuries, warping <strong>of</strong> instruments <strong>and</strong> the frustration <strong>of</strong><br />

trying to find missing instruments. 15 Using cassettes also helps<br />

avoid overloading the sterilizers with contaminated instruments,<br />

which can affect sterilization efficacy. Cassettes can be used for all<br />

instruments associated with specific procedures. A wide variety <strong>of</strong><br />

cassettes is available to meet all instrument needs. Cassette accessories<br />

are available <strong>and</strong> sized for specific items such as burs.<br />

The CDC guidelines state that “contaminated instruments<br />

should be h<strong>and</strong>led very carefully to prevent exposure to sharps<br />

instruments that can cause percutaneous injury. <strong>Instrument</strong>s<br />

should be placed in an appropriate container at the point <strong>of</strong> use<br />

to prevent percutaneous injuries during transportation to the<br />

instrument processing area.” Locking, covered tubs developed<br />

for transport <strong>and</strong> storage <strong>of</strong> consumable materials help reduce<br />

exposure to cross-contamination. Using a color-coded system<br />

for cassettes <strong>and</strong> tubs helps organization. Tubs are available in<br />

colors that match cassette rails, allowing staff to match tubs <strong>and</strong><br />

cassettes by procedure. For example, blue cassette rails <strong>and</strong> a blue<br />

tub can represent a composite procedure. All the consumable ma-<br />

www.ineedce.com 5

Table 2. <strong>Instrument</strong> Categories <strong>and</strong> Treatment<br />

Category Description Example Treatment<br />

Critical <strong>Instrument</strong>s penetrate mucosa or bone Surgical instruments Heat sterilization<br />

Semi-critical <strong>Instrument</strong>s come in contact with oral mucosa H<strong>and</strong>pieces Heat sterilization<br />

Heat-resistant instruments Heat sterilization<br />

Heat-sensitive instruments Immersion in high-level disinfectant/sterilant<br />

Non-critical <strong>Instrument</strong>s come in contact with intact skin Extra-oral instruments Immersion in high-level disinfectant/sterilant or<br />

process in intermediate-level disinfectant<br />

terials for composite procedures can be stored <strong>and</strong> organized in<br />

the blue tub <strong>and</strong> instrumentation stored in the cassette with blue<br />

rails, allowing for quick identification. <strong>Hu</strong>-<strong>Friedy</strong>’s Signature<br />

Series Tubs <strong>and</strong> matching IMS cassette system is an example <strong>of</strong><br />

this concept. Antibacterial properties such as Microban protection<br />

are integrated into the tub <strong>and</strong> tub components during the<br />

manufacturing process. Microban protection begins to work as<br />

soon as a microorganism comes into contact with the surface, <strong>and</strong><br />

works continuously to inhibit microbial growth that can cause<br />

stains, odors <strong>and</strong> product degradation. Microban is registered<br />

with the EPA for these applications.<br />

Cassettes with an efficient hole pattern are preferable, as they allow<br />

steam <strong>and</strong> chemicals to permeate while protecting instruments<br />

from protrusion. Cassettes are designed to fit into ultrasonic baths <strong>and</strong><br />

sterilizers— minimizing h<strong>and</strong>ling, saving time, increasing productivity<br />

<strong>and</strong> reducing the risk <strong>of</strong> infection from contaminated instruments.<br />

<strong>Instrument</strong>s <strong>and</strong> cassettes must be transported to <strong>and</strong> from the operatory<br />

<strong>and</strong> sterilization area in rigid, leak-pro<strong>of</strong> trays or containers. 16<br />

Tips for Cassettes <strong>and</strong> Tubs<br />

• Cassettes save time, prevent dulling <strong>of</strong> instruments <strong>and</strong> sharps<br />

injuries, prevent instrument loss, <strong>and</strong> reduce the chance <strong>of</strong> crosscontamination<br />

during transportation or processing.<br />

• Locking covered tubs developed for transport <strong>and</strong> storage <strong>of</strong> consumable<br />

materials help reduce cross contamination <strong>and</strong> protect materials<br />

if the tub is dropped.<br />

• Color-coded systems for cassettes <strong>and</strong> tubs help optimize <strong>of</strong>fice<br />

productivity <strong>and</strong> organization.<br />

• Antibacterial properties in tubs inhibit microbial growth, reducing<br />

staining <strong>and</strong> odors.<br />

• Matching cassette rail <strong>and</strong> tub colors by procedure allows for quick<br />

identification <strong>and</strong> improved workflow efficiency.<br />

Procedure tubs increase the efficiency <strong>of</strong> materials management<br />

<strong>and</strong> eliminate time-consuming tray preparation for every procedure.<br />

Having tubs preloaded with items for procedures such as<br />

endodontics, orthodontics, bonding, etc., streamlines setup <strong>and</strong><br />

increases efficiency. This system eliminates the time <strong>and</strong> frustration<br />

<strong>of</strong> having to gather several supplies from several areas. Specially<br />

designed dental supply tubs with dividers are great places to<br />

store your spare tips <strong>and</strong> h<strong>and</strong>les for instruments with replaceable<br />

tips <strong>and</strong> endo files. This system <strong>of</strong> organization can also include a<br />

simple pull tag for inventory reordering that is stored right in the<br />

tub. These tubs give you a clear view <strong>of</strong> the inventory <strong>and</strong> keep<br />

the items organized, saving you time, money <strong>and</strong> frustration.<br />

Precleaning solutions<br />

If instruments cannot be cleaned immediately, it is important to<br />

put them in a precleaning solution or spray them with a precleaning<br />

gel or foam. Leaving instruments sitting in the open air allows the<br />

debris to harden, making it more difficult to process. A precleaning<br />

solution or spray may contain enzymes to help break down debris,<br />

as well as rust inhibitors. <strong>Instrument</strong>s should be thoroughly rinsed<br />

after immersion. Sterilants <strong>and</strong> high-level disinfectants should not<br />

be used as holding solutions.<br />

Figure 6. Tubs <strong>and</strong> Cassettes; Syringe Holder<br />

Cleaning <strong>of</strong> instruments<br />

Cleaning is a vital step in instrument processing. Heavily contaminated<br />

instruments pose a threat to personnel <strong>and</strong> patients, as<br />

dried blood, saliva or dental materials may insulate bloodborne<br />

pathogens from the direct microbial effects <strong>of</strong> heat or chemical<br />

sterilization. Organic contaminants also may retard or inactivate<br />

chemical disinfectants, contributing to corrosion <strong>and</strong> interfering<br />

with the instrument’s functioning.<br />

OSHA st<strong>and</strong>ards state that “all procedures involving blood or<br />

other potential infectious materials shall be performed in such a manner<br />

as to minimize splashing, spraying, spattering, <strong>and</strong> generation <strong>of</strong><br />

droplets <strong>of</strong> these substances.” 17 Scrubbing instruments by h<strong>and</strong> is<br />

discouraged because it creates aerosols <strong>and</strong> the potential for sharps<br />

injuries. One 10-year study by the New York University College <strong>of</strong><br />

Dentistry found that 41 percent <strong>of</strong> exposures occurred during instrument<br />

cleanup. 18 Risks in the receiving area <strong>and</strong> during decontamination<br />

can be minimized by following simple steps. Using cassettes <strong>and</strong><br />

tubs <strong>and</strong> simply carrying instruments in a covered container saves<br />

time, costs very little <strong>and</strong> minimizes potential exposure. 9<br />

Automated systems are the most effective <strong>and</strong> safest method<br />

<strong>of</strong> decontamination, <strong>and</strong> substantially reduce instrument h<strong>and</strong>ling.<br />

4,19 Automated devices include ultrasonic cleaners <strong>and</strong><br />

automated dental washers. Ultrasonic cleaners utilize sound<br />

6 www.ineedce.com

waves above human audibility that result in the formation <strong>of</strong><br />

oscillating bubbles (cavitation) that then collapse <strong>and</strong> implode.<br />

Ultrasonic detergents are also available for use. More recently,<br />

some ultrasonic manufacturers have employed a new technology<br />

that uses a variable frequency as opposed to a fixed frequency in<br />

order to deliver reliable cavitation to all areas <strong>of</strong> the solution <strong>and</strong><br />

reduce the potential for hot spots that could weaken cleaning ability.<br />

Additionally, some manufacturers are using materials with<br />

antimicrobial activity in the interior chamber <strong>of</strong> the ultrasonic<br />

unit. Regardless <strong>of</strong> the ultrasonic unit selected, it is important to<br />

suspend the instruments in a basket in the ultrasonic bath, as laying<br />

them flat inside the bath can result in inadequate cleaning <strong>and</strong><br />

removal <strong>of</strong> debris. Also, refer to the manufacturer’s instructions<br />

on how much weight can been put in the ultrasonic, as it is very<br />

important not to overload the sterilizer. <strong>Instrument</strong>s should be<br />

either in cassettes or loose, do not b<strong>and</strong> your instruments together<br />

because they will not be as well cleaned. Ultrasonic baths also<br />

have timers, <strong>and</strong> instruments should remain in the bath for the<br />

full length <strong>of</strong> time recommended by the manufacturer. Enzymatic<br />

solutions should be changed every shift (at least daily) or more <strong>of</strong>ten<br />

if receiving heavy loads <strong>of</strong> contaminated instruments (degree<br />

<strong>of</strong> contamination <strong>and</strong> frequency <strong>of</strong> use are contributing factors in<br />

determining how <strong>of</strong>ten to change the ultrasonic solution).<br />

<strong>Instrument</strong> washers/disinfectors are a class <strong>of</strong> device traditionally<br />

used by central sterilization services such as those in hospitals.<br />

These medical devices wash, rinse <strong>and</strong> dry instruments, reducing<br />

the risk <strong>of</strong> pathogen transmission during subsequent instrument<br />

h<strong>and</strong>ling while processing. It is important to verify that the unit<br />

you are using has FDA clearance.<br />

Figure 7. Automated Cleaners<br />

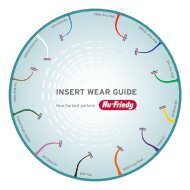

<strong>Instrument</strong> examination<br />

Examine all instruments closely, checking for broken instruments,<br />

burs <strong>and</strong> debris. Remove an instrument from service if it is damaged.<br />

The preferred remedy when instruments do not come out <strong>of</strong><br />

the ultrasonic bath or automatic washer free <strong>of</strong> debris is to run the<br />

instrument again to remove the debris or soak it in a presoak. If<br />

h<strong>and</strong> scrubbing becomes necessary:<br />

• Scrub one instrument at a time with a long-h<strong>and</strong>led brush.<br />

• Do not scrub until the item has been run through a mechanical<br />

cleaner to remove as much organic matter as possible.<br />

• Hold the instrument down low in the sink, preferably under<br />

water, to reduce aerosol formation as much as possible.<br />

Tips for <strong>Instrument</strong> Cleaning <strong>and</strong> Examination<br />

• Presoaks <strong>and</strong> sprays prevent debris from drying or hardening on<br />

instruments.<br />

• Automated systems are the most effective <strong>and</strong> safest method <strong>of</strong><br />

decontamination.<br />

• Test your ultrasonic bath weekly.<br />

Preparing <strong>and</strong> packaging, custom containers, wraps<br />

After cleaning the instruments, it is critical to thoroughly rinse <strong>and</strong><br />

dry the instruments. Rinsing is essential to remove chemical <strong>and</strong><br />

detergent residues. This prevents spotting, pitting <strong>and</strong> staining <strong>of</strong><br />

instruments by detergents, which can interfere with the smooth<br />

operation <strong>of</strong> instruments. Splashing should be minimized during<br />

rinsing. Packaging cleaned, dried instruments prior to placing<br />

them in the sterilizer is a st<strong>and</strong>ard <strong>of</strong> care that protects instruments.<br />

Following sterilization, storing the instruments in the<br />

packaging maintains their sterility until they are required for use<br />

on patients. Unprotected instruments can be recontaminated with<br />

dust or spatter or by coming in contact with nonsterile surfaces<br />

during transport, storage <strong>and</strong> tray setup. 20 Packaging used must be<br />

FDA-cleared as a medical device to guarantee that the wrapping<br />

has been tested <strong>and</strong> is permeable to the chemical <strong>and</strong> steam. There<br />

are wraps available for every size <strong>of</strong> instrument. 21 Packaging is not<br />

reusable unless otherwise indicated, <strong>and</strong> includes plastic tubing,<br />

wrap, <strong>and</strong> plastic/paper pouches. In addition, color-coded instrument<br />

rings <strong>and</strong> cassette ID labels help organize instrument processing.<br />

When it is necessary to process loose instruments, these<br />

should be packaged so that they lie in a single layer, permitting<br />

exposure <strong>of</strong> all areas <strong>of</strong> the instruments to the sterilizing agent. To<br />

maintain integrity <strong>of</strong> the package, follow the manufacturer’s recommendations<br />

for sealing the package <strong>and</strong> do not use staples, pins<br />

or paper clips to seal packages. Do not overstuff packages.<br />

To maintain the integrity <strong>of</strong> packaging, follow the manufacturer’s<br />

instructions on sealing packages.<br />

The new CDC 2008 guidelines state that an internal <strong>and</strong> external<br />

indicator should be in each package. Companies now have<br />

pouches with both an internal <strong>and</strong> an external indicator. The dates<br />

<strong>and</strong> record <strong>of</strong> the sterilizer used if there is more than one in your<br />

practice, should be placed on the packaging. This is recorded so<br />

that if a positive spore test is obtained, all packages for the dates<br />

involved can be pulled.<br />

Figure 8. Packaging <strong>and</strong> Cassette<br />

www.ineedce.com 7

Sterilization Techniques<br />

The basic methods <strong>of</strong> sterilization <strong>of</strong> heat-tolerant instruments are<br />

dry heat, steam under pressure (autoclave) <strong>and</strong> unsaturated chemical<br />

vapor. These are done with regulated medical devices that must<br />

be specifically designed to meet the needs <strong>of</strong> the dental setting.<br />

Each method has specific advantages <strong>and</strong> should be evaluated before<br />

a sterilizer is chosen. Take into consideration time, exposure to<br />

chemicals, temperature requirements <strong>and</strong> effects on instruments.<br />

If the instrument is heat sensitive <strong>and</strong> is semi-critical or noncritical,<br />

it can be sterilized by immersing it in an EPA-registered<br />

high-level disinfectant/sterilant, which may require up to 10 hours.<br />

Surface (intermediate-level) disinfectants may not be used in place<br />

<strong>of</strong> high-level disinfectants/sterilants. Current CDC guidelines<br />

from 2008 state: “H<strong>and</strong>pieces should be heat sterilized after each<br />

patient. H<strong>and</strong>pieces that cannot be heat sterilized should not be<br />

used.” High-level disinfection with chemical germicides cannot<br />

be biologically monitored to assure sterility, <strong>and</strong> extended contact<br />

with chemical germicides may corrode h<strong>and</strong>piece components.<br />

Most sterilizer malfunctions are due to operator error. The<br />

most common reasons are inadequate space between instruments,<br />

improper packaging, overloading <strong>and</strong> excessive packaging. In<br />

one study <strong>of</strong> Minnesota dental <strong>of</strong>fices, operator error rather than<br />

mechanical malfunction caused 87 percent <strong>of</strong> sterilization failures.<br />

Common factors in the improper use <strong>of</strong> sterilizers include chamber<br />

overload, low temperature setting, inadequate exposure time,<br />

failure to preheat the sterilizer <strong>and</strong> interruption <strong>of</strong> the cycle.<br />

Monitoring Sterilizers<br />

There are three basic ways to monitor the sterilizer. 22 These are:<br />

Mechanical Technique: This includes monitoring the cycle<br />

time <strong>and</strong> temperature by observing the gauges <strong>and</strong> displays during<br />

the process, <strong>and</strong> monitoring the computer printout, if available, to<br />

detect any malfunction. This should be done for every single load.<br />

Chemical Indicators: An indicator should be placed inside<br />

<strong>and</strong> outside every package or cassette. Many companies now<br />

manufacture packages that already contain both internal <strong>and</strong> external<br />

indicators. Chemical indicators are affixed on the outside <strong>of</strong><br />

each package to show that the package has been processed through<br />

a sterilization cycle, but do not prove that sterilization has been<br />

achieved. A chemical indicator should also be placed on the inside<br />

<strong>of</strong> each package to verify sterilant penetration. 23 This distinguishes<br />

processed from nonprocessed items. It monitors sterilization parameters<br />

such as time, temperature <strong>and</strong>, for autoclaves, pressure.<br />

It helps to identify gross sterilizer malfunction. 24<br />

Biological Indicators: This test is performed at least weekly<br />

for both test <strong>and</strong> control spores <strong>and</strong> with every load that contains<br />

an implantable device. It evaluates the effectiveness <strong>of</strong> the cycle<br />

killing Bacillus stearothermophilus or, more recently, Geobacillus<br />

stearothermophilus in autoclaves <strong>and</strong> chemical vapor sterilizers. In<br />

dry heat systems, it tests with Bacillus subtilis <strong>and</strong>, more recently,<br />

Bacillus atrophaeus. Tests can be run in the <strong>of</strong>fice or sent out for<br />

processing, <strong>and</strong> directly measure the effectiveness <strong>of</strong> the sterilization<br />

process. All implantable items must go through this process<br />

before they can be placed. It is important to follow the manufac-<br />

turer’s steps <strong>and</strong> to use the proper test for your specific sterilizer.<br />

Do not use any items from a failed test. Pull all items that were<br />

processed during the time period following the last test that did<br />

not fail. 25 Sending out for processing requires up to a 14-day waiting<br />

period, <strong>and</strong> there is a chance <strong>of</strong> mish<strong>and</strong>ling in the mail system.<br />

In-<strong>of</strong>fice biological monitoring systems are very simple to use <strong>and</strong><br />

provide initial results in as little as 24 hours. In-<strong>of</strong>fice biological<br />

monitoring assures the operator that no environmental factors<br />

have affected the testing during mailing <strong>and</strong> allows for planning<br />

<strong>of</strong> delivery <strong>of</strong> items such as implants that must have biological<br />

monitoring confirmed before placement.<br />

Table 4. Advantages <strong>of</strong> an <strong>Instrument</strong> Management System<br />

Safety Minimizes sharps h<strong>and</strong>ling <strong>and</strong> instrument h<strong>and</strong>ling<br />

Reduces risk <strong>of</strong> cross-contamination due to dropped<br />

instruments during transportation<br />

Cassettes fit in ultrasonic <strong>and</strong> automatic washer/cleaners<br />

Tubs are rigid <strong>and</strong> leak-pro<strong>of</strong><br />

Safer transportation <strong>of</strong> contaminated instruments<br />

Sterility Organizes instruments with proper spacing for efficient<br />

sterilization<br />

Avoids overloading the sterilizer<br />

Keeps instruments free from debris following sterilization<br />

Enables safe storage after sterilization, in packaging<br />

Productivity,<br />

Efficiency<br />

Color-coded cassettes <strong>and</strong> tubs organize instruments <strong>and</strong><br />

consumables by procedure type <strong>and</strong> are easy to identify<br />

Reduces set-up time with organized instrument storage<br />

Enhances chairside efficiency <strong>and</strong> easy staff training<br />

Requires less counter space than with trays<br />

Reduces manual sorting <strong>of</strong> instruments into pouches<br />

Increases available time for revenue-generating activities<br />

Cost Holds instruments securely during cleaning, protecting<br />

them from damage<br />

Eliminates loss <strong>of</strong> instruments during transportation<br />

Reduces potential for instrument damage during storage,<br />

transportation <strong>and</strong> processing<br />

Storage <strong>of</strong> instruments<br />

<strong>Instrument</strong>s should be stored in a clean place, preferably in a<br />

closed drawer or cupboard, away from the area where contaminated<br />

instruments are held <strong>and</strong> cleaned. They should not be stored<br />

under sinks or above sterilization devices. All instrument packaging<br />

should be checked for holes <strong>and</strong> tears before use. If there are<br />

any problems with the packaging, the instruments should be<br />

recleaned, repackaged <strong>and</strong> sterilized. Unwrapped items are easily<br />

contaminated. Unless an item is going to be used immediately,<br />

it should be wrapped. Unwrapped items should not be stored in<br />

drawers or cabinets because they cannot be kept sterile. 7,26<br />

Conclusions<br />

Quality, sterile dental instruments are the key to the practice <strong>of</strong><br />

dentistry. Having working, organized, sharp, debris-free instruments<br />

aids in production, quality <strong>of</strong> dentistry, safety <strong>and</strong> asepsis.<br />

There is a variety <strong>of</strong> methods available to reach the goal <strong>of</strong> properly<br />

8 www.ineedce.com

Table 3. Heat Sterilization Methods<br />

Method Temperature/Pressure Exposure Time (a) Advantages Precautions<br />

Steam autoclave (b) 121°C (250°F)<br />

13-30 min<br />

- Good penetration - Non-stainless steel items corrode<br />

115 kPa<br />

3.5-12 min<br />

- Nontoxic<br />

- May damage rubber & plastics<br />

134°C (273°F)<br />

216 kPa<br />

- Time efficient<br />

- Cannot use closed containers<br />

- Unwrapped items quickly contaminated after cycle<br />

Dry heat (c)<br />

160°C (320°F) 60-120 min - No corrosion<br />

- Long cycle time<br />

(oven-type)<br />

- Nontoxic<br />

- May damage rubber & plastics<br />

- Items are dry after cycle - Door can be opened during cycle, disrupting sterilization<br />

- Can use closed<br />

- Unwrapped items quickly contaminated after cycle<br />

containers (d)<br />

- Many wraps <strong>and</strong> pouches are not compatible<br />

Dry heat (c)<br />

191°C (375°F) 12 min wrapped - No corrosion<br />

- May damage rubber & plastics<br />

(rapid heat transfer)<br />

6 min unwrapped - Nontoxic<br />

- Door can be opened during cycle<br />

- Time efficient<br />

- Unwrapped items quickly contaminated after cycle<br />

- Items dry quickly<br />

- Many wraps <strong>and</strong> pouches are not compatible<br />

Unsaturated<br />

134°C (273°F) 216 kPa 20 min - No corrosion<br />

- May damage rubber & plastics<br />

chemical vapor (b)<br />

- Time efficient<br />

- Cannot use closed containers<br />

- Items dry quickly<br />

- Must use special solution<br />

- Uses hazardous chemical<br />

- Unwrapped items quickly contaminated after cycle<br />

(a) These exposure times relate only to the sterilization portion <strong>of</strong> the total cycle <strong>and</strong> do not include any warm-up, come-down or drying times. The exposure<br />

time may vary depending upon the load <strong>and</strong> should be verified during actual use with biological monitoring (spore-testing) <strong>and</strong> chemical indicators.<br />

(b) Monitor with spores <strong>of</strong> Bacillus stearothermophilus.<br />

(c) Monitor with spores <strong>of</strong> Bacillus subtilis.<br />

(d) Confirm by using biological indicator on inside <strong>of</strong> container.<br />

Adapted from: Miller, CH: Update on heat sterilization <strong>and</strong> sterilization monitoring. Compend Contin Educ Dent 1993;14:304-316.<br />

reprocessing instruments. Choosing a reliable, effective instrument<br />

management system <strong>and</strong> protocol that minimizes risk <strong>and</strong><br />

stress, maximizes productivity, saves money, <strong>and</strong> limits damage to<br />

instruments is essential for DHCPs, patients <strong>and</strong> the practice.<br />

References<br />

1 Tortora G, Funke B, Case C. 2007. Microbiology: An Introduction (9th Edition),<br />

408-431.<br />

2 Bently CE, Burkhart NW, Crawford JJ. Evaluating spatter <strong>and</strong> aerosol contamination<br />

during dental procedures. J Am Dent Assoc. 1994;125(5):579-84.<br />

3 Martin MV. New Concepts in Cross-Infection Control in Dentistry. Brit Dent J.<br />

June 8, 1990.<br />

4 Miller CH, Palenik CJ. Infection Control & Management <strong>of</strong> Hazardous Materials<br />

for the Dental Team. 3rd Edition, Elsevier Mosby, St. Louis, Mo., 2005.<br />

5 CDC. Guidelines for Infection Control in Dental Health-Care Settings, 2003.<br />

MMWR 2003:52 (No. RR-17).<br />

6 CDC Guidelines: From Policy to Practice by OSAP, 2003, Annapolis, Md.<br />

7 Palenik CJ, Burke FJT, Coulter WA, Cheung SW. Cross-Infection Control,<br />

Improving <strong>and</strong> Monitoring Autoclave Performance in Dental Practice. Brit Dent J.<br />

1990;187:581-84.<br />

8 Kurita H, Kurashina K, Honda T. Nosocomial transmission <strong>of</strong> methicillinresistant<br />

Staphylococcus aureus via the surfaces <strong>of</strong> the dental operatory. Br Dent J.<br />

2006;201(5):297-300.<br />

9 Kohn WG, Collins AS, Clevel<strong>and</strong> JL, Jarte JA, Eklund KJ, Malvitz DM. Center for<br />

Disease Control <strong>and</strong> Prevention. Guidelines for infection control in dental healthcare<br />

settings, 2003. MMWR recomm Rep. 2003;52 (RR-17):1-16.<br />

10 Molinari JA, Palenik CJ. Environmental surface infection control. Compend Contin<br />

Ed Dent. 2004;25(suppl):30-7.<br />

11 Andrews, N. A Clean Sweep, RDH Magazine, Nov. 2008.<br />

12 Ramos-Gomez F, Ellison J, Greenspan D, Bird W, Lowe S, Gerberding JL. Accidental<br />

Exposures to Blood <strong>and</strong> Body Fluid Among Health Care Workers in Dental Teaching<br />

Clinics: A Prospective Study. J Am Dent Assoc. 1997;58(3):217-20.<br />

13 Panagakos FS, Silverstein J. Incidence <strong>of</strong> Percutaneous Injuries at a Dental School:<br />

A Four-Year Retrospective Study. Am J Infect Control. 1997;25:330-4.<br />

14 OSAP, Managing patient care items <strong>and</strong> environmental surfaces. (Appendix C).<br />

From Policy to Practice: OSAP’s Guide to the Guidelines. Annapolis, Md.: OSAP,<br />

2004:142.<br />

15 Sanchez E, Mac Donald G. Decontaminating dental instruments: testing the<br />

effectiveness <strong>of</strong> selected methods. J Am Dent Assoc. 1995;126;359-62.<br />

16 Miller CH, Palenik CJ. Infection control & management <strong>of</strong> hazardous materials for<br />

the dental team (3rd Edition). Elsevier Mosby, St. Louis, Mo., 2005.<br />

17 U.S. Department <strong>of</strong> Labor, Occupational Safety <strong>and</strong> Health Administration. 29<br />

CFR part 1910.1030, Occupational exposure to bloodborne pathogens, final rules.<br />

Federal Register 1991,56(235)64004-64182.<br />

18 Younai FS, Murphy CD, Kotelchuck D. Milieu in Dental Schools <strong>and</strong> Practice,<br />

Occupational Exposure to Blood in a Dental Teaching Environment: Results <strong>of</strong> a<br />

Ten-Year Surveillance Study. J Dent Ed.; 65(5):426-48.<br />

19 CDC. Guidelines for environmental infection control in health-care facilities:<br />

recommendations <strong>of</strong> the CDC <strong>and</strong> the Healthcare Infection Control Advisory<br />

Committee. MMWR 2003; 52(no. RR-10) Oper Dent. 2005;30(1):16-25.<br />

20 Organization for Safety <strong>and</strong> Asepsis: Position Paper: <strong>Instrument</strong> <strong>Processing</strong>, Jan.<br />

1997. Accessed Sept. 2008.<br />

21 Rutala WA, Weber DJ. Choosing Sterilization Wrap for Surgical Packs. Infect Cont<br />

Today. 2000;4:64-70.<br />

22 Organization for Safety <strong>and</strong> Asepsis Procedures Research Foundation. Monthly<br />

Focus: The Sterilization Process. Annapolis, Md.: OSAP, 1997.<br />

23 Centers for Disease Control. Guideline for Disinfection <strong>and</strong> Sterilization in<br />

Healthcare Facilities, 2008. Available at: www.cdc.gov/ncidod/dhqp/pdf/<br />

guidelines/Disinfection_Nov_2008.pdf. Accessed Nov. 2008.<br />

24 Association <strong>of</strong> the Advancement <strong>of</strong> Medical <strong>Instrument</strong>ation. Chemical indicators:<br />

guidance for the selection, use <strong>and</strong> interpretation <strong>of</strong> results. AAMI Technical<br />

Information Report No 25. Arlington, Va.: Association for the Advancement <strong>of</strong><br />

Medical <strong>Instrument</strong>ation, 1999.<br />

25 Nickerson P, Bhuta G, Orton B, Alvin B. Monitoring dental sterilizers’ effectiveness<br />

using biological indicators. J Dent Hyg. 1990;64(2):69-73.<br />

26 Rosa AC et al. Effects <strong>of</strong> H<strong>and</strong>ling <strong>and</strong> Storage on Sterile Dental <strong>Instrument</strong>s. Acta<br />

Odontol Lainoam. 2001;14(1-2):35-39.<br />

Author Pr<strong>of</strong>ile<br />

Noel Br<strong>and</strong>on Kelsch, RDHAP<br />

Noel Br<strong>and</strong>on Kelsch is a freelance cartoonist, writer, international speaker <strong>and</strong><br />

Registered Dental Hygienist in Alternative Practice. Her articles have been published<br />

in dental <strong>and</strong> nursing trade magazines. She has written articles for National<br />

Journals <strong>and</strong> Corporations on Methamphetamine abuse. Her passion for getting<br />

information to the dental pr<strong>of</strong>essional <strong>and</strong> the public on the oral effects <strong>of</strong> this<br />

devastating drug has taken her from NBC news to ESPN. Noel has received many<br />

national awards including Colgate Bright Smiles Bright Futures, RDH Magazine<br />

Sun Star Butler Award <strong>of</strong> Distinction, USA magazine Make a Difference Day<br />

award, Presidents Service award, Foster Parent <strong>of</strong> the Year, <strong>and</strong> is a five-time winner<br />

<strong>of</strong> the Castroville Artichoke cook <strong>of</strong>f! Noel is the current President <strong>of</strong> California<br />

Dental Hygienists Association, a member <strong>of</strong> Organization for Safety <strong>and</strong> Asepsis<br />

Procedures <strong>and</strong> board member <strong>of</strong> Simi Valley Free Clinic.<br />

Disclaimer<br />

The author(s) <strong>of</strong> this course has/have no commercial ties with the sponsors or the<br />

providers <strong>of</strong> the unrestricted educational grant for this course.<br />

Reader Feedback<br />

We encourage your comments on this or any PennWell course. For your convenience, an<br />

online feedback form is available at www.ineedce.com.<br />

www.ineedce.com 9

1. The conditions that must exist in order for a<br />

disease to occur are called the ________.<br />

a. chance <strong>of</strong> infection<br />

b. chain <strong>of</strong> transmission<br />

c. chain <strong>of</strong> infection<br />

d. none <strong>of</strong> the above<br />

2. In general, it is more likely that disease<br />

would be transmitted from clinician to<br />

patient than vice versa.<br />

a. True<br />

b. False<br />

3. Indirect contact with pathogenic microorganisms<br />

in the dental setting does not lead to<br />

disease transmission.<br />

a. True<br />

b. False<br />

4. St<strong>and</strong>ard precautions guard against<br />

exposure to _________.<br />

a. blood<br />

b. blood <strong>and</strong> saliva<br />

c. blood <strong>and</strong> sweat<br />

d. all body fluids except sweat<br />

5. The DHCP should treat every patient as a<br />

potential source <strong>of</strong> infection.<br />

a. True<br />

b. False<br />

6. Single-use surface barriers _________.<br />

a. protect surfaces from contamination<br />

b. should be used on as many surfaces as possible<br />

c. reduce exposure to chemicals<br />

d. all <strong>of</strong> the above<br />

7. <strong>Instrument</strong> processing is a key component <strong>of</strong><br />

infection control.<br />

a. True<br />

b. False<br />

8. Using instrument cassettes _________.<br />

a. protects instruments<br />

b. limits DHCP contact with contaminated instruments<br />

c. keeps instruments free <strong>of</strong> debris<br />

d. all <strong>of</strong> the above<br />

9. Using st<strong>and</strong>ardized set-ups <strong>and</strong> an instrument<br />

cassette system saves time in the dental<br />

<strong>of</strong>fice <strong>and</strong> helps increase productivity.<br />

a. True<br />

b. False<br />

10. If necessary, single-use disposable instruments<br />

can be sterilized.<br />

a. True<br />

b. False<br />

11. A sharps container should be kept in a central<br />

location rather than in each operatory.<br />

a. True<br />

b. False<br />

12. One available device that melts down <strong>and</strong><br />

compresses used needles ________.<br />

a. helps reduce sharps injuries during sharps removal <strong>and</strong><br />

<strong>of</strong>fers a disposal alternative<br />

b. <strong>of</strong>fers a disposal alternative<br />

c. meets OSHA <strong>and</strong> EPA requirements<br />

d. b <strong>and</strong> c<br />

Questions<br />

13. In all states, intact, broken <strong>and</strong> empty<br />

carpules can be disposed <strong>of</strong> in the general<br />

trash.<br />

a. True<br />

b. False<br />

14. Puncture- <strong>and</strong> chemical-resistant utility<br />

gloves _________.<br />

a. should be worn during instrument processing by the<br />

DHCP h<strong>and</strong>ling contaminated instruments<br />

b. should be inspected at least daily for cracks <strong>and</strong> integrity<br />

c. are a requirement based on OSHA guidelines<br />

d. all <strong>of</strong> the above<br />

15. Cassettes <strong>and</strong> instrument trays are placed<br />

in the _________ area for removal <strong>of</strong> debris<br />

before processing.<br />

a. sterilization<br />

b. receiving, cleaning <strong>and</strong> decontamination<br />

c. prepping<br />

d. any <strong>of</strong> the above<br />

16. An instrument management system that<br />

includes the use <strong>of</strong> instrument tubs <strong>and</strong><br />

cassettes is the most efficient way to manage<br />

consumable products <strong>and</strong> instruments.<br />

a. True<br />

b. False<br />

17. A biological indicator test is performed<br />

_________ for test <strong>and</strong> control spores.<br />

a. daily<br />

b. weekly<br />

c. monthly<br />

d. as <strong>of</strong>ten as deemed necessary, depending on the<br />

infection risk from a given <strong>of</strong>fice’s patients<br />

18. To save storage space, sterilized instruments<br />

may be carefully stored in their<br />

packaging above the sterilizer.<br />

a. True<br />

b. False<br />

19. Critical instruments _________.<br />

a. require heat sterilization or must be single-use<br />

disposable<br />

b. require chemical or heat sterilization or must be<br />

single-use disposable<br />

c. require disinfection or must be single-use disposable<br />

d. must be disposable<br />

20. Antibacterial properties incorporated into<br />

instrument tubs _________.<br />

a. ensure that no cross-infection is possible<br />

b. help prevent odors <strong>and</strong> staining <strong>of</strong> the tub<br />

c. help prevent degradation <strong>of</strong> the tub<br />

d. b <strong>and</strong> c<br />

21. Cassettes with an efficient hole pattern<br />

_________.<br />

a. allow steam to permeate the cassette<br />

b. allow chemicals to permeate the cassette<br />

c. protect instruments from protrusion<br />

d. all <strong>of</strong> the above<br />

22. A precleaning solution may contain<br />

enzymes to help break down debris, as well<br />

as rust inhibitors.<br />

a. True<br />

b. False<br />

23. One ten-year study found that _________<br />

<strong>of</strong> sharps injury exposures occurred during<br />

instrument cleaning.<br />

a. 21 percent<br />

b. 31 percent<br />

c. 41 percent<br />

d. 51 percent<br />

24. Automated systems are the safest <strong>and</strong> most<br />

effective method <strong>of</strong> instrument reprocessing.<br />

a. True<br />

b. False<br />

25. After cleaning the instruments, it is critical<br />

to thoroughly rinse <strong>and</strong> dry the instruments.<br />

a. True<br />

b. False<br />

26. Regular wrapping paper can be used for<br />

instrument packaging.<br />

a. True<br />

b. False<br />

27. The new CDC guidelines <strong>of</strong> 2008 state that<br />

packaging must have __________.<br />

a. an external indicator<br />

b. an internal indicator<br />

c. a lateral indicator<br />

d. both an external <strong>and</strong> an internal indicator<br />

28. According to the 2008 CDC guidelines,<br />

h<strong>and</strong>pieces can be chemically sterilized if<br />

they are heat-sensitive.<br />

a. True<br />

b. False<br />

29. Sterilizers can be monitored using<br />

__________.<br />

a. mechanical techniques<br />

b. biological indicators<br />

c. chemical indicators<br />

d. all <strong>of</strong> the above<br />

30. A reliable, effective instrument management<br />

system used as part <strong>of</strong> an infection<br />

control program _________.<br />

a. minimizes risk<br />

b. maximizes productivity<br />

c. limits damage to instruments<br />

d. all <strong>of</strong> the above<br />

10 www.ineedce.com

AUTHOR DISCLAIMER<br />

The author(s) <strong>of</strong> this course has/have no commercial ties with the sponsors or the providers <strong>of</strong><br />

the unrestricted educational grant for this course.<br />

SPONSOR/PROVIDER<br />

This course was made possible through an unrestricted educational grant from <strong>Hu</strong>-<br />

<strong>Friedy</strong>, Inc.. No manufacturer or third party has had any input into the development <strong>of</strong><br />

course content. All content has been derived from references listed, <strong>and</strong> or the opinions<br />

<strong>of</strong> clinicians. Please direct all questions pertaining to PennWell or the administration <strong>of</strong><br />

this course to Machele Galloway, 1421 S. Sheridan Rd., Tulsa, OK 74112 or macheleg@<br />

pennwell.com.<br />

COURSE EVALUATION <strong>and</strong> PARTICIPANT FEEDBACK<br />

We encourage participant feedback pertaining to all courses. Please be sure to complete the<br />

survey included with the course. Please e-mail all questions to: macheleg@pennwell.com.<br />

ANSWER SHEET<br />

<strong>Effective</strong> <strong>and</strong> <strong>Productive</strong> <strong>Instrument</strong> <strong>Processing</strong><br />

Name: Title: Specialty:<br />

Address: E-mail:<br />

City: State: ZIP: Country:<br />

Telephone: Home ( ) Office ( )<br />

Requirements for successful completion <strong>of</strong> the course <strong>and</strong> to obtain dental continuing education credits: 1) Read the entire course. 2) Complete all<br />

information above. 3) Complete answer sheets in either pen or pencil. 4) Mark only one answer for each question. 5) A score <strong>of</strong> 70% on this test will earn<br />

you 4 CE credits. 6) Complete the Course Evaluation below. 7) Make check payable to PennWell Corp.<br />

Educational Objectives<br />

1. Describe the chain <strong>of</strong> infection <strong>and</strong> modes <strong>of</strong> transmission <strong>of</strong> microorganisms in the dental <strong>of</strong>fice<br />

2. Know <strong>and</strong> underst<strong>and</strong> the four basic principles <strong>and</strong> goals to reduce microbial transmission<br />

3. Know which instruments must be sterilized, the methods by which this can be achieved, <strong>and</strong> the role <strong>and</strong> importance <strong>of</strong><br />

external <strong>and</strong> internal indicators on packaging<br />

4. Underst<strong>and</strong> instrument processing steps <strong>and</strong> the use <strong>of</strong> instrument management systems in this process.<br />

Course Evaluation<br />

Please evaluate this course by responding to the following statements, using a scale <strong>of</strong> Excellent = 5 to Poor = 0.<br />

1. Were the individual course objectives met? Objective #1: Yes No Objective #3: Yes No<br />

Objective #2: Yes No Objective #4: Yes No<br />

2. To what extent were the course objectives accomplished overall? 5 4 3 2 1 0<br />

3. Please rate your personal mastery <strong>of</strong> the course objectives. 5 4 3 2 1 0<br />

4. How would you rate the objectives <strong>and</strong> educational methods? 5 4 3 2 1 0<br />

5. How do you rate the author’s grasp <strong>of</strong> the topic? 5 4 3 2 1 0<br />

6. Please rate the instructor’s effectiveness. 5 4 3 2 1 0<br />

7. Was the overall administration <strong>of</strong> the course effective? 5 4 3 2 1 0<br />

8. Do you feel that the references were adequate? Yes No<br />

9. Would you participate in a similar program on a different topic? Yes No<br />

10. If any <strong>of</strong> the continuing education questions were unclear or ambiguous, please list them.<br />

___________________________________________________________________<br />

11. Was there any subject matter you found confusing? Please describe.<br />

___________________________________________________________________<br />

___________________________________________________________________<br />

12. What additional continuing dental education topics would you like to see?<br />

___________________________________________________________________<br />

___________________________________________________________________<br />

PLEASE PHOTOCOPY ANSWER SHEET FOR ADDITIONAL PARTICIPANTS.<br />

INSTRUCTIONS<br />

All questions should have only one answer. Grading <strong>of</strong> this examination is done<br />

manually. Participants will receive confirmation <strong>of</strong> passing by receipt <strong>of</strong> a verification<br />

form. Verification forms will be mailed within two weeks after taking an examination.<br />

EDUCATIONAL DISCLAIMER<br />

The opinions <strong>of</strong> efficacy or perceived value <strong>of</strong> any products or companies mentioned<br />

in this course <strong>and</strong> expressed herein are those <strong>of</strong> the author(s) <strong>of</strong> the course <strong>and</strong> do not<br />

necessarily reflect those <strong>of</strong> PennWell.<br />

Completing a single continuing education course does not provide enough information<br />

to give the participant the feeling that s/he is an expert in the field related to the course<br />

topic. It is a combination <strong>of</strong> many educational courses <strong>and</strong> clinical experience that<br />

allows the participant to develop skills <strong>and</strong> expertise.<br />

COURSE CREDITS/COST<br />

All participants scoring at least 70% (answering 21 or more questions correctly) on the<br />

examination will receive a verification form verifying 4 CE credits. The formal continuing<br />

education program <strong>of</strong> this sponsor is accepted by the AGD for Fellowship/Mastership<br />

credit. Please contact PennWell for current term <strong>of</strong> acceptance. Participants are urged to<br />

contact their state dental boards for continuing education requirements. PennWell is a<br />

California Provider. The California Provider number is 4527. The cost for courses ranges<br />

from $49.00 to $110.00.<br />

Many PennWell self-study courses have been approved by the Dental Assisting National<br />

Board, Inc. (DANB) <strong>and</strong> can be used by dental assistants who are DANB Certified to meet<br />