Pneumatic Assembly Tools - Specma Tools

Pneumatic Assembly Tools - Specma Tools

Pneumatic Assembly Tools - Specma Tools

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

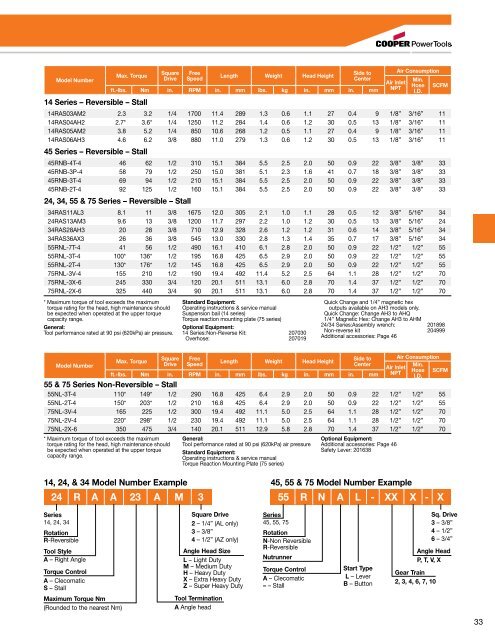

Model Number<br />

Model Number<br />

Max . Torque<br />

Max . Torque<br />

Square<br />

Drive<br />

Square<br />

Drive<br />

Free<br />

Speed<br />

Length Weight Head Height<br />

Side to<br />

Center<br />

ft .-lbs . Nm in . RPM in . mm lbs . kg in . mm in . mm<br />

55 & 75 Series Non-Reversible – Stall<br />

Air Inlet<br />

NPT<br />

Air Consumption<br />

55NL-3T-4 0* 49* /2 290 6 .8 425 6 .4 2 .9 2 .0 50 0 .9 22 /2” /2” 55<br />

55NL-2T-4 50* 203* /2 2 0 6 .8 425 6 .4 2 .9 2 .0 50 0 .9 22 /2” /2” 55<br />

75NL-3V-4 65 225 /2 300 9 .4 492 . 5 .0 2 .5 64 . 28 /2” /2” 70<br />

75NL-2V-4 220* 298* /2 230 9 .4 492 . 5 .0 2 .5 64 . 28 /2” /2” 70<br />

75NL-2X-6 350 475 3/4 40 20 . 5 2 .9 5 .8 2 .8 70 .4 37 /2” /2” 70<br />

* .Maximum .torque .of .tool .exceeds .the .maximum .<br />

torque .rating .for .the .head, .high .maintenance .should .<br />

be .expected .when .operated .at .the .upper .torque .<br />

capacity .range .<br />

Free<br />

Speed<br />

Length Weight Head Height<br />

General:<br />

Tool .performance .rated .at .90 .psi .(620kPa) .air .pressure<br />

Standard Equipment:<br />

Operating .instructions .& .service .manual<br />

Torque .Reaction .Mounting .Plate .(75 .series)<br />

Side to<br />

Center<br />

ft .-lbs . Nm in . RPM in . mm lbs . kg in . mm in . mm<br />

Air Inlet<br />

NPT<br />

Optional Equipment:<br />

Additional .accessories: .Page .46<br />

Safety .Lever: .20 638<br />

Air Consumption<br />

14 Series – Reversible – Stall<br />

4RAS03AM2 2 .3 3 .2 /4 700 .4 289 .3 0 .6 . 27 0 .4 9 /8” 3/ 6”<br />

4RAS04AH2 2 .7* 3 .6* /4 250 .2 284 .4 0 .6 .2 30 0 .5 3 /8” 3/ 6”<br />

4RAS05AM2 3 .8 5 .2 /4 850 0 .6 268 .2 0 .5 . 27 0 .4 9 /8” 3/ 6”<br />

4RAS06AH3 4 .6 6 .2 3/8 880 .0 279 .3 0 .6 .2 30 0 .5 3 /8” 3/ 6”<br />

45 Series – Reversible – Stall<br />

45RNB-4T-4 46 62 /2 3 0 5 . 384 5 .5 2 .5 2 .0 50 0 .9 22 3/8” 3/8” 33<br />

45RNB-3P-4 58 79 /2 250 5 .0 38 5 . 2 .3 .6 4 0 .7 8 3/8” 3/8” 33<br />

45RNB-3T-4 69 94 /2 2 0 5 . 384 5 .5 2 .5 2 .0 50 0 .9 22 3/8” 3/8” 33<br />

45RNB-2T-4 92 25 /2 60 5 . 384 5 .5 2 .5 2 .0 50 0 .9 22 3/8” 3/8” 33<br />

24, 34, 55 & 75 Series – Reversible – Stall<br />

34RAS AL3 8 . 3/8 675 2 .0 305 2 . .0 . 28 0 .5 2 3/8” 5/ 6” 34<br />

24RAS 3AM3 9 .6 3 3/8 200 .7 297 2 .2 .0 .2 30 0 .5 3 3/8” 5/ 6” 24<br />

34RAS28AH3 20 28 3/8 7 0 2 .9 328 2 .6 .2 .2 3 0 .6 4 3/8” 5/ 6” 34<br />

34RAS36AX3 26 36 3/8 545 3 .0 330 2 .8 .3 .4 35 0 .7 7 3/8” 5/ 6” 34<br />

55RNL-7T-4 4 56 /2 490 6 . 4 0 6 . 2 .8 2 .0 50 0 .9 22 /2” /2” 55<br />

55RNL-3T-4 00* 36* /2 95 6 .8 425 6 .5 2 .9 2 .0 50 0 .9 22 /2” /2” 55<br />

55RNL-2T-4 30* 76* /2 45 6 .8 425 6 .5 2 .9 2 .0 50 0 .9 22 /2” /2” 55<br />

75RNL-3V-4 55 2 0 /2 90 9 .4 492 .4 5 .2 2 .5 64 . 28 /2” /2” 70<br />

75RNL-3X-6 245 330 3/4 20 20 . 5 3 . 6 .0 2 .8 70 .4 37 /2” /2” 70<br />

75RNL-2X-6 325 440 3/4 90 20 . 5 3 . 6 .0 2 .8 70 .4 37 /2” /2” 70<br />

* .Maximum .torque .of .tool .exceeds .the .maximum .<br />

torque .rating .for .the .head, .high .maintenance .should .<br />

be .expected .when .operated .at .the .upper .torque .<br />

capacity .range .<br />

General:<br />

Tool .performance .rated .at .90 .psi .(620kPa) .air .pressure .<br />

14, 24, & 34 Model Number Example<br />

24 R A A 23 A M 3<br />

Series<br />

4, .24, .34<br />

Rotation<br />

R-Reversible .<br />

Tool Style<br />

A .– .Right .Angle<br />

Torque Control<br />

A .– .Clecomatic<br />

S .– .Stall<br />

Maximum Torque Nm<br />

(Rounded .to .the .nearest .Nm)<br />

Standard Equipment:<br />

Operating .instructions .& .service .manual<br />

Suspension .bail .( 4 .series)<br />

Torque .reaction .mounting .plate .(75 .series)<br />

Optional Equipment:<br />

4 .Series: .Non-Reverse .Kit: . 207030<br />

. .Overhose: . . 2070 9<br />

Square Drive<br />

2 .– . /4” .(AL .only)<br />

3 .– .3/8”<br />

4 .– . /2” .(AZ .only)<br />

Angle Head Size<br />

L .– .Light .Duty<br />

M .– .Medium .Duty<br />

H .– .Heavy .Duty<br />

X .– .Extra .Heavy .Duty<br />

Z .– .Super .Heavy .Duty<br />

Tool Termination<br />

A .Angle .head<br />

Min .<br />

Hose<br />

I .D .<br />

Min .<br />

Hose<br />

I .D .<br />

SCFM<br />

. .Quick .Change .and . /4” .magnetic .hex .<br />

. . . . .outputs .available .on .AH3 .models .only .<br />

. .Quick .Change: .Change .AH3 .to .AHQ<br />

. . /4” .Magnetic .Hex: .Change .AH3 .to .AHM<br />

24/34 .Series:<strong>Assembly</strong> .wrench: . 20 898<br />

. .Non-reverse .kit . 204999 .<br />

Additional .accessories: .Page .46<br />

SCFM<br />

45, 55 & 75 Model Number Example<br />

55 R N A L - XX X - X<br />

Series<br />

45, .55, .75<br />

Rotation<br />

N-Non .Reversible .<br />

R-Reversible<br />

Nutrunner<br />

Torque Control<br />

A .– .Clecomatic<br />

– .– .Stall<br />

Start Type<br />

L .– .Lever<br />

B .– .Button<br />

Sq . Drive<br />

3 .– .3/8”<br />

4 .– . /2”<br />

6 .– .3/4”<br />

Angle Head<br />

P, T, V, X<br />

Gear Train<br />

2, 3, 4, 6, 7, 10<br />

33