Demand-Controlled Ventilation For Commercial ... - Halton Company

Demand-Controlled Ventilation For Commercial ... - Halton Company

Demand-Controlled Ventilation For Commercial ... - Halton Company

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

1,200<br />

1,100<br />

1,000<br />

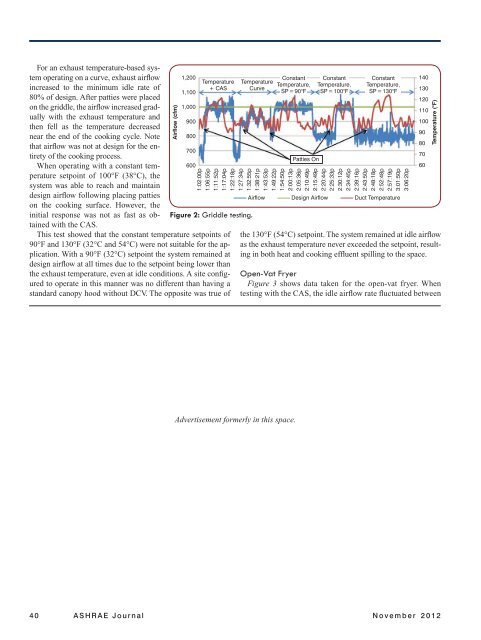

Figure 2: Griddle testing.<br />

<strong>For</strong> an exhaust temperature-based system<br />

operating on a curve, exhaust airflow<br />

increased to the minimum idle rate of<br />

80% of design. After patties were placed<br />

on the griddle, the airflow increased gradually<br />

with the exhaust temperature and<br />

then fell as the temperature decreased<br />

near the end of the cooking cycle. Note<br />

that airflow was not at design for the entirety<br />

of the cooking process.<br />

When operating with a constant temperature<br />

setpoint of 100°F (38°C), the<br />

system was able to reach and maintain<br />

design airflow following placing patties<br />

on the cooking surface. However, the<br />

initial response was not as fast as obtained<br />

with the CAS.<br />

This test showed that the constant temperature setpoints of<br />

90°F and 130°F (32°C and 54°C) were not suitable for the application.<br />

With a 90°F (32°C) setpoint the system remained at<br />

design airflow at all times due to the setpoint being lower than<br />

the exhaust temperature, even at idle conditions. A site configured<br />

to operate in this manner was no different than having a<br />

standard canopy hood without DCV. The opposite was true of<br />

Airflow (cfm)<br />

900<br />

800<br />

700<br />

600<br />

Temperature<br />

+ CAS<br />

Temperature<br />

Curve<br />

1:02:00p<br />

1:06:55p<br />

1:11:52p<br />

1:17:04p<br />

1:22:18p<br />

1:27:34p<br />

1:32:55p<br />

1:38:21p<br />

1:43:53p<br />

1:49:22p<br />

1:54:50p<br />

2:00:13p<br />

2:05:36p<br />

2:10:49p<br />

2:15:49p<br />

2:20:44p<br />

2:25:33p<br />

2:30:12p<br />

2:34:45p<br />

2:39:16p<br />

2:43:50p<br />

2:48:18p<br />

2:52:48p<br />

2:57:19p<br />

3:01:50p<br />

3:06:20p<br />

Airflow<br />

Constant<br />

Temperature,<br />

SP = 90°F<br />

Patties On<br />

Design Airflow<br />

Constant<br />

Temperature,<br />

SP = 100°F<br />

Constant<br />

Temperature,<br />

SP = 130°F<br />

Duct Temperature<br />

140<br />

130<br />

120<br />

110<br />

100<br />

90<br />

80<br />

70<br />

60<br />

the 130°F (54°C) setpoint. The system remained at idle airflow<br />

as the exhaust temperature never exceeded the setpoint, resulting<br />

in both heat and cooking effluent spilling to the space.<br />

Open-Vat Fryer<br />

Figure 3 shows data taken for the open-vat fryer. When<br />

testing with the CAS, the idle airflow rate fluctuated between<br />

Temperature (°F)<br />

Advertisement formerly in this space.<br />

40 ASHRAE Journal November 2012