Low Voltage Components Catalog

Low Voltage Components Catalog

Low Voltage Components Catalog

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

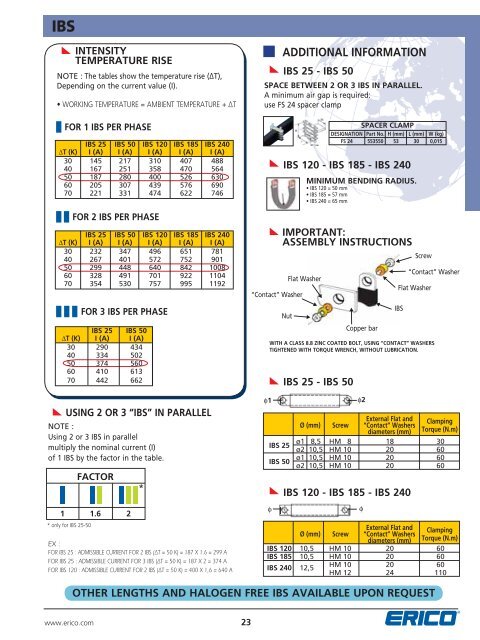

IBS<br />

INTENSITY<br />

TEMPERATURE RISE<br />

NOTE : The tables show the temperature rise (ΔT),<br />

Depending on the current value (I).<br />

• WORKING TEMPERATURE = AMBIENT TEMPERATURE + ΔT<br />

FOR 1 IBS PER PHASE<br />

IBS 25 IBS 50 IBS 120 IBS 185 IBS 240<br />

ΔT (K) I (A) I (A) I (A) I (A) I (A)<br />

30 145 217 310 407 488<br />

40 167 251 358 470 564<br />

50 187 280 400 526 630<br />

60 205 307 439 576 690<br />

70 221 331 474 622 746<br />

FOR 2 IBS PER PHASE<br />

IBS 25 IBS 50 IBS 120 IBS 185 IBS 240<br />

ΔT (K) I (A) I (A) I (A) I (A) I (A)<br />

30 232 347 496 651 781<br />

40 267 401 572 752 901<br />

50 299 448 640 842 1008<br />

60 328 491 701 922 1104<br />

70 354 530 757 995 1192<br />

FOR 3 IBS PER PHASE<br />

IBS 25 IBS 50<br />

ΔT (K) I (A) I (A)<br />

30 290 434<br />

40 334 502<br />

50 374 560<br />

60 410 613<br />

70 442 662<br />

USING 2 OR 3 “IBS” IN PARALLEL<br />

NOTE :<br />

Using 2 or 3 IBS in parallel<br />

multiply the nominal current (I)<br />

of 1 IBS by the factor in the table.<br />

FACTOR<br />

1 1.6 2<br />

* only for IBS 25-50<br />

*<br />

EX :<br />

FOR IBS 25 : ADMISSIBLE CURRENT FOR 2 IBS (ΔT = 50 K) = 187 X 1.6 = 299 A<br />

FOR IBS 25 : ADMISSIBLE CURRENT FOR 3 IBS (ΔT = 50 K) = 187 X 2 = 374 A<br />

FOR IBS 120 : ADMISSIBLE CURRENT FOR 2 IBS (ΔT = 50 K) = 400 X 1,6 = 640 A<br />

“Contact” Washer<br />

φ1<br />

φ<br />

ADDITIONAL INFORMATION<br />

IBS 25 - IBS 50<br />

SPACE BETWEEN 2 OR 3 IBS IN PARALLEL.<br />

A minimum air gap is required:<br />

use FS 24 spacer clamp<br />

IMPORTANT:<br />

ASSEMBLY INSTRUCTIONS<br />

Nut<br />

Flat Washer<br />

IBS 25 - IBS 50<br />

SPACER CLAMP<br />

DESIGNATION Part No. H (mm) L (mm) W (kg)<br />

FS 24 553550 53 30 0,015<br />

IBS 120 - IBS 185 - IBS 240<br />

MINIMUM BENDING RADIUS.<br />

• IBS 120 = 50 mm<br />

• IBS 185 = 57 mm<br />

• IBS 240 = 65 mm<br />

Copper bar<br />

φ2<br />

Ø (mm) Screw<br />

External Flat and Clamping<br />

“Contact” Washers<br />

diameters (mm) Torque (N.m)<br />

IBS 25<br />

ø1 8,5 HM 08 18 30<br />

ø2 10,5 HM 10 20 60<br />

IBS 50<br />

ø1 10,5 HM 10 20 60<br />

ø2 10,5 HM 10 20 60<br />

IBS 120 - IBS 185 - IBS 240<br />

φ<br />

Screw<br />

“Contact” Washer<br />

Flat Washer<br />

Ø (mm) Screw<br />

External Flat and Clamping<br />

“Contact” Washers<br />

diameters (mm) Torque (N.m)<br />

IBS 120 10,5 HM 10 20 60<br />

IBS 185 10,5 HM 10 20 60<br />

IBS 240 12,5<br />

HM 10 20 60<br />

HM 12 24 110<br />

IBS<br />

WITH A CLASS 8.8 ZINC COATED BOLT, USING “CONTACT” WASHERS<br />

TIGHTENED WITH TORQUE WRENCH, WITHOUT LUBRICATION.<br />

OTHER LENGTHS AND HALOGEN FREE IBS AVAILABLE UPON REQUEST<br />

www.erico.com 23