Rivscrew® PL

Rivscrew® PL

Rivscrew® PL

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

RIVSCREW ® <strong>PL</strong><br />

RIVSCREW<br />

® <strong>PL</strong><br />

The Ideal<br />

Solution for Chal<br />

allen<br />

engin<br />

ging Situation<br />

uations<br />

Risk<br />

sk of untr<br />

ntrained operat<br />

ator or over er tightenin<br />

ening g screw<br />

ews during g instal<br />

allation ation and strip<br />

trippin<br />

ping g inser<br />

sert thread<br />

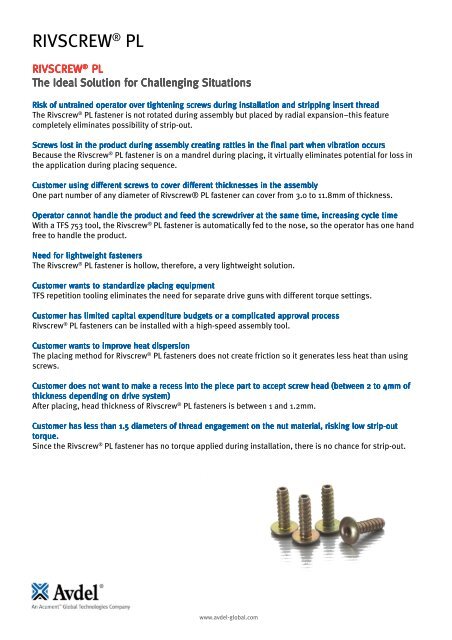

The Rivscrew ® <strong>PL</strong> fastener is not rotated during assembly but placed by radial expansion–this feature<br />

completely eliminates possibility of strip-out.<br />

Screw<br />

ews lost in the product<br />

during g assemb<br />

sembly<br />

ly creatin<br />

ating g rattl<br />

attles in the final<br />

al par<br />

art when vibr<br />

ibration occur<br />

urs<br />

Because the Rivscrew ® <strong>PL</strong> fastener is on a mandrel during placing, it virtually eliminates potential for loss in<br />

the application during placing sequence.<br />

Customer usin<br />

ing g differ<br />

erent<br />

ent screw<br />

ews to o cover er differ<br />

erent<br />

ent thickne<br />

knesse<br />

ses in the assemb<br />

sembly<br />

ly<br />

One part number of any diameter of Rivscrew® <strong>PL</strong> fastener can cover from 3.0 to 11.8mm of thickness.<br />

Operat<br />

ator or cannot<br />

handl<br />

andle e the product<br />

and feed the screwdriv<br />

ewdriver er at the same time, increasin<br />

ing g cycle e time<br />

With a TFS 753 tool, the Rivscrew ® <strong>PL</strong> fastener is automatically fed to the nose, so the operator has one hand<br />

free to handle the product.<br />

Need for lightweight<br />

fastener<br />

eners<br />

The Rivscrew ® <strong>PL</strong> fastener is hollow, therefore, a very lightweight solution.<br />

Customer wants<br />

to stand<br />

andar<br />

ardiz<br />

dize plac<br />

acin<br />

ing equipment<br />

TFS repetition tooling eliminates the need for separate drive guns with different torque settings.<br />

Customer has limited capit<br />

apital<br />

al expendit<br />

xpenditur<br />

ure budg<br />

udgets<br />

or a comp<br />

omplic<br />

licat<br />

ated appr<br />

proval<br />

proc<br />

ocess<br />

Rivscrew ® <strong>PL</strong> fasteners can be installed with a high-speed assembly tool.<br />

Customer wants<br />

to improve heat<br />

disper<br />

persion<br />

The placing method for Rivscrew ® <strong>PL</strong> fasteners does not create friction so it generates less heat than using<br />

screws.<br />

Customer does not want<br />

to mak<br />

ake a rec<br />

ecess into the piece e par<br />

art to accept<br />

screw head (between een 2 to 4mm of<br />

thickne<br />

kness depending on drive system)<br />

After placing, head thickness of Rivscrew ® <strong>PL</strong> fasteners is between 1 and 1.2mm.<br />

Customer has less than 1.5 diamet<br />

ameter<br />

ers of thread engagement<br />

ement on the nut mat<br />

ateri<br />

erial, risk<br />

skin<br />

ing low strip-out<br />

tor<br />

orque.<br />

Since the Rivscrew ® <strong>PL</strong> fastener has no torque applied during installation, there is no chance for strip-out.<br />

www.avdel-global.com