The Effects of Higher Strength and Associated Concrete Properties ...

The Effects of Higher Strength and Associated Concrete Properties ...

The Effects of Higher Strength and Associated Concrete Properties ...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

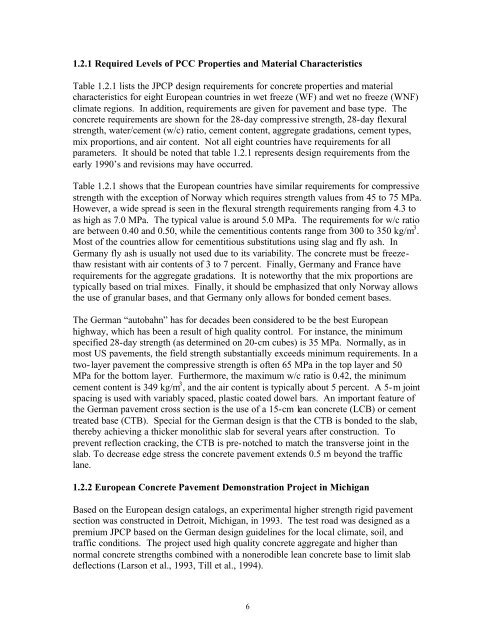

1.2.1 Required Levels <strong>of</strong> PCC <strong>Properties</strong> <strong>and</strong> Material Characteristics<br />

Table 1.2.1 lists the JPCP design requirements for concrete properties <strong>and</strong> material<br />

characteristics for eight European countries in wet freeze (WF) <strong>and</strong> wet no freeze (WNF)<br />

climate regions. In addition, requirements are given for pavement <strong>and</strong> base type. <strong>The</strong><br />

concrete requirements are shown for the 28-day compressive strength, 28-day flexural<br />

strength, water/cement (w/c) ratio, cement content, aggregate gradations, cement types,<br />

mix proportions, <strong>and</strong> air content. Not all eight countries have requirements for all<br />

parameters. It should be noted that table 1.2.1 represents design requirements from the<br />

early 1990’s <strong>and</strong> revisions may have occurred.<br />

Table 1.2.1 shows that the European countries have similar requirements for compressive<br />

strength with the exception <strong>of</strong> Norway which requires strength values from 45 to 75 MPa.<br />

However, a wide spread is seen in the flexural strength requirements ranging from 4.3 to<br />

as high as 7.0 MPa. <strong>The</strong> typical value is around 5.0 MPa. <strong>The</strong> requirements for w/c ratio<br />

are between 0.40 <strong>and</strong> 0.50, while the cementitious contents range from 300 to 350 kg/m 3 .<br />

Most <strong>of</strong> the countries allow for cementitious substitutions using slag <strong>and</strong> fly ash. In<br />

Germany fly ash is usually not used due to its variability. <strong>The</strong> concrete must be freezethaw<br />

resistant with air contents <strong>of</strong> 3 to 7 percent. Finally, Germany <strong>and</strong> France have<br />

requirements for the aggregate gradations. It is noteworthy that the mix proportions are<br />

typically based on trial mixes. Finally, it should be emphasized that only Norway allows<br />

the use <strong>of</strong> granular bases, <strong>and</strong> that Germany only allows for bonded cement bases.<br />

<strong>The</strong> German “autobahn” has for decades been considered to be the best European<br />

highway, which has been a result <strong>of</strong> high quality control. For instance, the minimum<br />

specified 28-day strength (as determined on 20-cm cubes) is 35 MPa. Normally, as in<br />

most US pavements, the field strength substantially exceeds minimum requirements. In a<br />

two-layer pavement the compressive strength is <strong>of</strong>ten 65 MPa in the top layer <strong>and</strong> 50<br />

MPa for the bottom layer. Furthermore, the maximum w/c ratio is 0.42, the minimum<br />

cement content is 349 kg/m 3 , <strong>and</strong> the air content is typically about 5 percent. A 5-m joint<br />

spacing is used with variably spaced, plastic coated dowel bars. An important feature <strong>of</strong><br />

the German pavement cross section is the use <strong>of</strong> a 15-cm lean concrete (LCB) or cement<br />

treated base (CTB). Special for the German design is that the CTB is bonded to the slab,<br />

thereby achieving a thicker monolithic slab for several years after construction. To<br />

prevent reflection cracking, the CTB is pre-notched to match the transverse joint in the<br />

slab. To decrease edge stress the concrete pavement extends 0.5 m beyond the traffic<br />

lane.<br />

1.2.2 European <strong>Concrete</strong> Pavement Demonstration Project in Michigan<br />

Based on the European design catalogs, an experimental higher strength rigid pavement<br />

section was constructed in Detroit, Michigan, in 1993. <strong>The</strong> test road was designed as a<br />

premium JPCP based on the German design guidelines for the local climate, soil, <strong>and</strong><br />

traffic conditions. <strong>The</strong> project used high quality concrete aggregate <strong>and</strong> higher than<br />

normal concrete strengths combined with a nonerodible lean concrete base to limit slab<br />

deflections (Larson et al., 1993, Till et al., 1994).<br />

6