Workshop Brochure - Society of Petroleum Engineers

Workshop Brochure - Society of Petroleum Engineers

Workshop Brochure - Society of Petroleum Engineers

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

WORKSHOP<br />

Deepwater: Going Deep to Get Ahead<br />

<strong>Workshop</strong> Supporters<br />

Supporting the Event<br />

Supporting the event helps <strong>of</strong>fset the<br />

cost <strong>of</strong> producing them and allows<br />

SPE to keep the attendance price<br />

within reach <strong>of</strong> operations-level<br />

individuals, those who benefit most<br />

from these technical workshops.<br />

Platinum Supporter<br />

Silver Supporter<br />

Bronze Supporter<br />

Gala Dinner<br />

Entertainment<br />

Supporters benefit both directly and<br />

indirectly by having their names<br />

associated with a specific workshop.<br />

20 October 2011<br />

Luncheon Supporter<br />

20 October 2011<br />

C<strong>of</strong>fee Breaks Supporter<br />

21 October 2011<br />

C<strong>of</strong>fee Breaks Supporter<br />

While SPE prohibits any type <strong>of</strong><br />

commercialism within the conference<br />

hall itself, the society recognises that<br />

sponsoring companies <strong>of</strong>fer valuable<br />

information to attendees outside the<br />

technical sessions.<br />

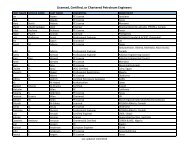

Supporter Categories<br />

Supporters are <strong>of</strong>fered on a first<br />

come basis. Please contact SPE to<br />

verify the availability <strong>of</strong> a particular<br />

category. Existing supporters have<br />

the opportunity to renew the same<br />

level <strong>of</strong> support for annual workshops.<br />

Supporter packages remaining are as<br />

follows:<br />

• Platinum Supporter<br />

• Gold Supporter<br />

• Silver Supporter<br />

• Bronze Supporter<br />

• Gala Dinner Entertainment<br />

Supporter<br />

• Speaker Gifts Supporter<br />

• Lanyards Supporter<br />

• C<strong>of</strong>fee Breaks Supporter–Per Day<br />

• Luncheons Supporter–Per Day<br />

• Audio-Visual Equipment Supporter<br />

Supporter Benefits<br />

In addition to onsite recognition; SPE<br />

will recognise supporters on the SPE<br />

website and in all printed material for<br />

the workshop. Based on the category<br />

selected, supporting companies can<br />

also receive a selected number <strong>of</strong><br />

complimentary local registrations.<br />

For More Information<br />

For a detailed list <strong>of</strong> available<br />

categories, including benefits<br />

and pricing, contact Loreen Nisha, at<br />

lnisha@spe.org.<br />

SAVE BY<br />

REGISTERING<br />

BEFORE<br />

26 SEPTEMBER 2011<br />

Schedule<br />

Wednesday, 19 October 2011<br />

1700–1730 hours Steering Committee Meeting<br />

1730–1830 hours Session Chairmen/Speakers Meeting<br />

1730–1830 hours SPE Registration and Badge Collection<br />

1830–1930 hours <strong>Workshop</strong> Inauguration and Keynote Speech<br />

2015–2230hours Gala Dinner<br />

Thursday, 20 October 2011<br />

0900–1030 hours Session 1: Case Histories<br />

Deepwater oil and gas developments are being executed in increasingly demanding and high-cost, frontier<br />

environments. To accomplish this feat, the operator’s project teams must work together with service companies<br />

and technology vendors to deliver integrated, innovative, and flexible solutions. Existing developments provide<br />

the opportunity to see how successful these partnerships are and what solutions and concepts have been<br />

developed. This session will provide an insight into “Ideation to Production” <strong>of</strong> three assets and seek to gather<br />

lessons <strong>of</strong> success from across the world.<br />

1030–1045 hours C<strong>of</strong>fee Break<br />

1045–1215 hours Session 2: Exploration and Appraisal<br />

Successfully developing a deepwater prospect depends heavily upon the ability to understand and reduce<br />

risks and manage costs. Gathering quality information during exploration and appraisal activities is critical so<br />

that decisions can be made on sound footings. Yet, in the deepwater environment, the costs <strong>of</strong> exploration<br />

and appraisal are steep and the activities need to be carefully considered and focused on gathering the right<br />

information. This session will consider the technologies and methods, being applied within the industry, and<br />

which assist in delivering sufficient sub-surface information to allow key development decisions to be made.<br />

1215–1230 hours Refresher Break<br />

1230–1400 hours Session 3: Drilling and Completions<br />

The Macondo incident cost 11 precious lives and caused unprecedented environmental impact. It highlighted<br />

how difficult it is to control a deepwater subsea blowout and was an eye opener into the difficulties and<br />

uncertainties for deepwater subsea intervention. At a time when most <strong>of</strong> the deepwater zones are fast-tracking<br />

provision <strong>of</strong> emergency response kits, it is apt to discuss the lessons learnt from the incident and the progress<br />

the industry has made in building capping and oil spill response tools. With regulatory agencies becoming more<br />

stringent on deepwater safety and environment issues, operators have the imperative to be fully prepared for the<br />

eventualities.<br />

Also, automated drilling systems are now common on most newly built rigs. With emphasis on efficiency and<br />

safety, the human intervention with drilling tools is being brought to a minimum. The technology is now being<br />

viewed as a necessity, instead <strong>of</strong> just as an option.<br />

Design and subsequent management <strong>of</strong> the drilling riser system, to withstand the range <strong>of</strong> subsea loads, is<br />

a critical function to avoid failure. This session will consider how advancements in technology for deepwater<br />

drilling and production have to be matched by the ability to connect the surface equipment safely to the seabed.<br />

The industry is attempting to move ahead from running numerous casing pipes to other solutions in deepwater<br />

drilling; dual gradient drilling mud and managed pressure drilling (MPD) now find favour. While the use <strong>of</strong><br />

MPD in deepwater provides challenges, an increasing number <strong>of</strong> wells are being drilled with MPD to counter<br />

simultaneous loss and kick situations.<br />

1400–1445 hours Luncheon<br />

1445–1615 hours Session 4: Surface Facilities<br />

Development <strong>of</strong> oil and gas fields in a deepwater environment needs leading edge, technology based, design<br />

for safe and effective surface facilities. A range <strong>of</strong> facilities are available, e.g. TLP, SPAR, or floating structures<br />

like FPSO, FSU, semisubmersibles, FLNG, etc. With deeper fields, the challenges related to riser and mooring<br />

engineering and flowline design and installation become more complex and need special engineering<br />

consideration. This session will focus on the challenges and the cutting edge technologies required to conquer<br />

the deepwater fields.