Komatsu VIEWS - Komatsu America Corp.

Komatsu VIEWS - Komatsu America Corp.

Komatsu VIEWS - Komatsu America Corp.

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

<strong>Komatsu</strong> and Rio Tinto<br />

Take Business Relationship<br />

to the Next Level<br />

Customers in Focus<br />

<strong>Komatsu</strong> AHS Trucks Pass Trials<br />

and Set for Deployment at Rio Tinto Mines<br />

in Australia<br />

I<br />

n November 2011, <strong>Komatsu</strong> Ltd. and Rio Tinto<br />

entered into a Memorandum of Understanding<br />

(MOU) for the deployment of at least 150<br />

<strong>Komatsu</strong> Autonomous Haulage System (AHS)<br />

trucks into Rio Tinto’s Pilbara Iron Ore operations<br />

in Western Australia by the end of 2015, with<br />

delivery of equipment commencing in 2012. This<br />

MOU follows the successful completion of a threeyear<br />

trial of five autonomous 930E-ATs, which<br />

demonstrated clear value in the areas of health,<br />

safety and productivity, at Rio Tinto’s West<br />

Angelas mine in the Pilbara region.<br />

Since completing the trials at the West Angelas<br />

operations, these five original trucks have moved<br />

to Rio Tinto’s Yandicoogina Junction South East<br />

(JSE) mine. Yandicoogina is the highest producing<br />

iron ore mine in the Pilbara. A further five<br />

930E-ATs have been purchased, giving the JSE<br />

mine a total fleet of 10 AHS trucks.<br />

This fleet, which is being loaded using <strong>Komatsu</strong><br />

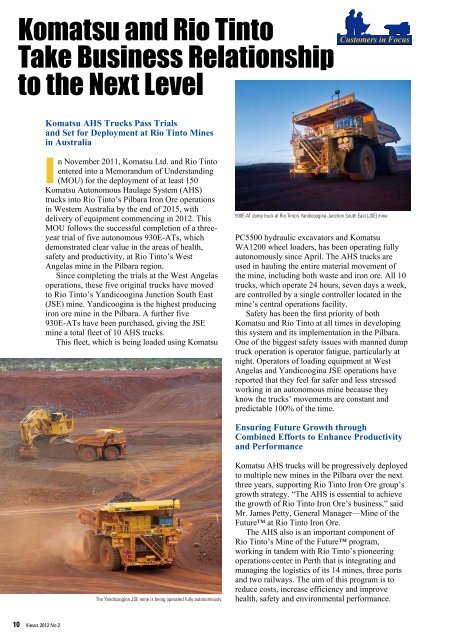

930E-AT dump truck at Rio Tinto’s Yandicoogina Junction South East (JSE) mine<br />

PC5500 hydraulic excavators and <strong>Komatsu</strong><br />

WA1200 wheel loaders, has been operating fully<br />

autonomously since April. The AHS trucks are<br />

used in hauling the entire material movement of<br />

the mine, including both waste and iron ore. All 10<br />

trucks, which operate 24 hours, seven days a week,<br />

are controlled by a single controller located in the<br />

mine’s central operations facility.<br />

Safety has been the first priority of both<br />

<strong>Komatsu</strong> and Rio Tinto at all times in developing<br />

this system and its implementation in the Pilbara.<br />

One of the biggest safety issues with manned dump<br />

truck operation is operator fatigue, particularly at<br />

night. Operators of loading equipment at West<br />

Angelas and Yandicoogina JSE operations have<br />

reported that they feel far safer and less stressed<br />

working in an autonomous mine because they<br />

know the trucks’ movements are constant and<br />

predictable 100% of the time.<br />

Ensuring Future Growth through<br />

Combined Efforts to Enhance Productivity<br />

and Performance<br />

The Yandicoogina JSE mine is being operated fully autonomously.<br />

<strong>Komatsu</strong> AHS trucks will be progressively deployed<br />

to multiple new mines in the Pilbara over the next<br />

three years, supporting Rio Tinto Iron Ore group’s<br />

growth strategy. “The AHS is essential to achieve<br />

the growth of Rio Tinto Iron Ore’s business,” said<br />

Mr. James Petty, General Manager—Mine of the<br />

Future at Rio Tinto Iron Ore.<br />

The AHS also is an important component of<br />

Rio Tinto’s Mine of the Future program,<br />

working in tandem with Rio Tinto’s pioneering<br />

operations center in Perth that is integrating and<br />

managing the logistics of its 14 mines, three ports<br />

and two railways. The aim of this program is to<br />

reduce costs, increase efficiency and improve<br />

health, safety and environmental performance.<br />

10 Views 2012 No.2