DURETHANE® Polyurethane System Form P-138 (9/90 ... - BAPS

DURETHANE® Polyurethane System Form P-138 (9/90 ... - BAPS

DURETHANE® Polyurethane System Form P-138 (9/90 ... - BAPS

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

B. Aluminum (General Aviation Aircraft, truck bodies and misc) Apply DX 533<br />

Aluminum Cleaner. Rinse with water. Condition surface with DX 503 Aluminum<br />

Conditioner. Rinse with water. Dry and apply DP Epoxy Primer/401 Catalyst and<br />

DURETHANE® topcoat color.<br />

C. Cold rolled steel or steel plate (with little or no rust or mil scale). Treat surface with<br />

DX 579 Metal Cleaner. Rinse with water. Apply DX 520 Metal Conditioner. Rinse<br />

with water. Dry and apply DP Epoxy Primer/401 Catalyst and DURETHANE<br />

topcoat color.<br />

D. Cold Rolled Steel or Steel Plate (with heavy rusting or mil scale). Sand blast<br />

surface to gray metal. Blow off dust with clean compressed air. Clean with<br />

ACRYLI-CLEAN® Wax and Grease Remover (DX 330). Apply DP Epoxy<br />

Primer/401 Catalyst and DURETHANE topcoat color.<br />

E. Old DURETHANE, Epoxy, or other catalyzed finishes. Wash with ACRYLI-CLEAN<br />

Wax and Grease Remover (DX 330). Sand thoroughly with 220 grit or finer DA or<br />

320-400 wet or dry. Reclean surfaces. Apply DURETHANE Primer (DPU 35/301)<br />

or DP Epoxy Primer/401 Catalyst, then topcoat with DURETHANE color.<br />

F. Fiberglass. New molded parts should be washed with a clean cloth liberally<br />

soaked with alcohol. Dry with clean white cloths. Wash thoroughly with<br />

ACRYLI-CLEAN Wax and Grease Remover (DX 330). Lightly sand to remove all<br />

gloss with 320 grit or finer. Avoid sanding through gelcoat - make sure<br />

fiberglass strands are not showing. Reclean surface. Apply DP Epoxy Primer/401<br />

Catalyst and DURETHANE topcoat color.<br />

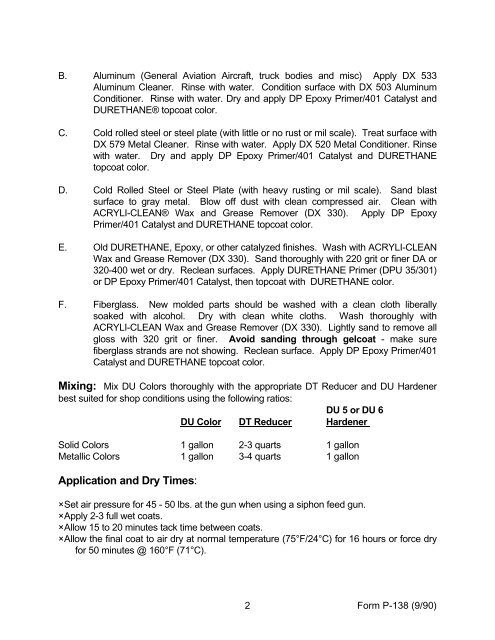

Mixing: Mix DU Colors thoroughly with the appropriate DT Reducer and DU Hardener<br />

best suited for shop conditions using the following ratios:<br />

DU 5 or DU 6<br />

DU Color DT Reducer Hardener<br />

Solid Colors 1 gallon 2-3 quarts 1 gallon<br />

Metallic Colors 1 gallon 3-4 quarts 1 gallon<br />

Application and Dry Times:<br />

×Set air pressure for 45 - 50 lbs. at the gun when using a siphon feed gun.<br />

×Apply 2-3 full wet coats.<br />

×Allow 15 to 20 minutes tack time between coats.<br />

×Allow the final coat to air dry at normal temperature (75°F/24°C) for 16 hours or force dry<br />

for 50 minutes @ 160°F (71°C).<br />

2 <strong>Form</strong> P-<strong>138</strong> (9/<strong>90</strong>)