CASES

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

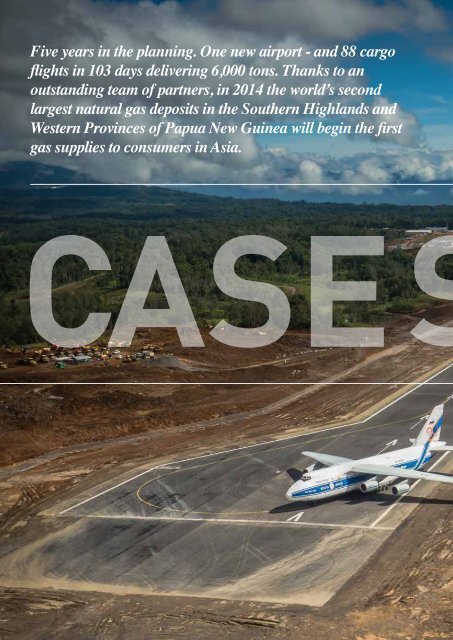

Five years in the planning. One new airport - and 88 cargo<br />

flights in 103 days delivering 6,000 tons. Thanks to an<br />

outstanding team of partners, in 2014 the world’s second<br />

largest natural gas deposits in the Southern Highlands and<br />

Western Provinces of Papua New Guinea will begin the first<br />

gas supplies to consumers in Asia.<br />

<strong>CASES</strong>

TUDY<br />

This is the story of how logistics,<br />

infrastructure and gas production<br />

and processing specialists came<br />

together to turn an ambitious project<br />

plan into a reality.

cargosuper market<br />

CASE STUDY<br />

WITH TEAMWORK,<br />

ANYTHING IS<br />

POSSIBLE<br />

Finding natural oil and gas<br />

energy reserves is challenging<br />

enough but extracting them<br />

can be even more complex and<br />

capital intensive and leaves no<br />

margin for error.<br />

Increasingly, the world’s leading energy<br />

corporations have to target more remote<br />

regions of the planet to develop new<br />

processing and pumping facilities. The<br />

risks are high but so too are the rewards<br />

and economic benefits for both industry<br />

and national and local economies.<br />

In Papua New Guinea, the discovery of<br />

natural gas deposits in its Hela, Southern<br />

Highlands and Western Provinces<br />

offered the potential to increase the<br />

country’s GDP. ExxonMobil PNG Limited,<br />

the operator of the PNG LNG Project,<br />

estimates that over the life of the gas<br />

production and processing project, over<br />

nine trillion cubic feet of gas will be<br />

produced and sold. The company began<br />

construction of the Project in 2010 and<br />

the first LNG will be exported in the<br />

second half of 2014.<br />

But first there was a major<br />

logistics challenge.<br />

Building a gas conditioning plant in<br />

the Highlands of Papua New Guinea<br />

was not going to be easy. The region<br />

is predominantly rugged mountainous<br />

terrain and conditions are made more<br />

challenging by the 9,000mm of rainfall in<br />

the area throughout the year.<br />

Logistically the biggest challenge was to<br />

deliver equipment and materials from<br />

the ports of Lae and Port Moresby to<br />

the Hides Gas Conditioning Plant, which<br />

is located in the Southern Highlands of<br />

Papua New Guinea at an elevation of over<br />

1500m. A large percentage of the 800kms<br />

of road from Lae are dirt tracks with<br />

gradients of over 20% and there are 99<br />

bridge crossings on the route as well. The<br />

maximum gross vehicle weight on a lot<br />

of the bridges is limited to 60,000kg, so<br />

with prime mover and trailer weights the<br />

maximum cargo weight via road was low<br />

by industry standards at around 25,000<br />

kilos. Additionally, the road between<br />

Lae and Hides has been subject to road<br />

closures due to landslides, washouts and<br />

other uncontrollable factors.<br />

Over 7,000 loads have already travelled<br />

this route. However, the Hides plant<br />

also required a lot of large, delicate<br />

and sensitive equipment in order to<br />

commence operation and the poor quality<br />

roads and restrictions between Lae and<br />

the jobsite were deemed not suitable<br />

to transport these materials. Another<br />

transport solution was clearly required.<br />

ExxonMobil recognised that to overcome<br />

these challenges would require an<br />

innovative logistics solution – and a lot of<br />

‘thinking outside of the box’.

PNG LNG PROJECT<br />

cargosuper market<br />

‘For us, it was not just a commercial project but the chance to test ourselves again’<br />

ExxonMobil contracted Volga-Dnepr<br />

Airlines, the world’s largest transporter<br />

of outsize and heavyweight air cargo,<br />

which over more than 20 years had<br />

demonstrated its unique ability to ‘make<br />

the impossible possible’.<br />

When teams of specialists from<br />

ExxonMobil and Volga-Dnepr first<br />

got together in 2008 to discuss the<br />

project, one question dominated the<br />

conversation: was it theoretically possible<br />

to fly thousands of tonnes of large, heavy,<br />

complex and sensitive equipment into<br />

the remote Highlands of Papua New<br />

Guinea to enable the building of a gas<br />

conditioning plant?<br />

The combined expertise and knowledge<br />

of the two organisations established that<br />

undertaking such a complex air logistics<br />

task was indeed possible – but first they<br />

had to build an airport.<br />

For Volga-Dnepr, working on projects<br />

some years in advance of performing<br />

an actual flight operation is part and<br />

parcel of its unique place in the world<br />

of aviation. The size and design of big<br />

pieces of high value industrial equipment,<br />

aircraft components and space satellites<br />

are often based on their ability to fit<br />

into the airline’s fleet of giant Antonov<br />

An-124 freighters because major global<br />

corporations recognise the vital role<br />

Volga-Dnepr plays in their supply chain.<br />

In the first phase of their cooperation, a<br />

joint team from ExxonMobil and Volga-<br />

Dnepr travelled to Papua New Guinea<br />

to evaluate four proposed locations<br />

for a new Highlands airport. This was<br />

subsequently reduced to two sites<br />

following inspections and, ultimately, one<br />

location in Komo based on Volga-Dnepr’s<br />

study of load lists and route options.<br />

Back in the UK, members of ExxonMobil’s<br />

PNG LNG Project team met with the<br />

airline to plan how many An-124 flights<br />

would be required, which routes would<br />

be used, the frequency of operations,<br />

the length of the project and flight<br />

programme, and the costs involved.<br />

In 2010, work began on the new<br />

Komo Airfield.<br />

To be able to handle An-124 freighter<br />

operations would require building Papua<br />

New Guinea’s longest paved runway at<br />

3,200m in length and 45m wide. Once<br />

complete the new airport would be able<br />

continued on page 12

cargosuper market<br />

CASE STUDY<br />

‘deugro and Volga-Dnepr Airlines<br />

were brought together early on in<br />

the project in putting together a<br />

unique trailer loading and<br />

off-loading concept to reduce<br />

the overall ground handling<br />

times for the aircraft’<br />

continued from page 11<br />

to welcome the world’s largest seriesproduced<br />

cargo aircraft with its 73 metre<br />

wingspan, maximum take-off weight of<br />

392 tons and payload of up to 120 tonnes.<br />

It would feed construction equipment<br />

and materials virtually to the door of the<br />

gas processing site through a series of<br />

90-minute flights from Port Moresby.<br />

The Soviet-built An-124 makes light<br />

work of logistics projects well beyond the<br />

capability of other commercial airliners.<br />

In terms of cargo handling, the aircraft is<br />

virtually self sufficient. Craneless loading<br />

and offloading technology saves hours<br />

and eliminates any additional costs arising<br />

from the need for third party handling<br />

equipment. In this case, reducing the time<br />

the aircraft needed to spend on the ground<br />

was essential to the one-flight-per-day<br />

schedule set for the project.<br />

Another key partner in the Hides project<br />

was deugro, which was awarded the<br />

contract for the international freight<br />

forwarding and logistics package as well<br />

as the Papua New Guinea in-country<br />

marshalling facility in Port Moresby and<br />

heavy-haul service package for delivery to<br />

the Hides Gas Conditioning Plant – in total,<br />

managing the delivery of some 72,500<br />

metric tonnes.<br />

Via the establishment of a purpose-built<br />

marshalling yard facility at Jacksons<br />

International Airport, deugro’s Port<br />

Moresby office managed the inbound<br />

customs clearance, storage and handling<br />

of the heavy and outsize pieces of<br />

equipment prior to their ultimate loading<br />

onto the Antonov 124 aircraft for onwards<br />

delivery to Komo.<br />

In Komo, it was again deugro that was<br />

responsible for receiving the heavy and<br />

outsize equipment from the An-124 aircraft<br />

and delivering the equipment over the final<br />

25 kilometers to the plant.<br />

Richard Jürgens, Project Manager for<br />

deugro Projects (Australia) says: “A project<br />

of this scale has never been attempted<br />

within PNG. The infrastructure one<br />

takes for granted in a developed Oil &<br />

Gas environment was not present. This<br />

meant a massive investment in additional<br />

resources, skills and subsequent training<br />

and infrastructure development was<br />

needed, to up-scale the roads, bridges,<br />

transportation equipment and network<br />

to cope with the logistics demands of the<br />

various contractors.<br />

Route surveys, transport studies and<br />

infrastructure analysis in respect to bridge<br />

strength and capacity, road surfaces,<br />

bends and inclines were conducted by<br />

deugro’s transport engineering team more<br />

than a year in advance to ensure that the<br />

ultimate transport equipment utilized<br />

remained the best fit to what essentially<br />

became forever changing conditions.<br />

”The remote and at times volatile location,<br />

the lack of locally available support<br />

equipment and technicians and adverse<br />

weather conditions steered the logistics<br />

approach, particularly from a heavy haul<br />

and project logistics perspective, to one of<br />

being completely self-reliant.<br />

“This lent to establishing a fully competent<br />

team of experienced operators familiar<br />

with the risks of operating heavy transport<br />

equipment in such harsh conditions,<br />

to consistently ensure the delivery of<br />

materials to the construction site day<br />

after day.“<br />

A key factor in the success of the logistics<br />

project was the cooperation of the partners<br />

from an early stage. Richard Jürgens<br />

adds: “deugro and Volga-Dnepr Airlines<br />

were brought together early on in the<br />

‘The remote and at times volatile location,the lack of locally available<br />

support equipment and technicians and adverse weather conditions steered the<br />

logistics approach’

PNG LNG PROJECT<br />

cargosuper market<br />

‘A project of this scale has never<br />

been attempted within PNG.<br />

The infrastructure one takes for<br />

granted in a developed Oil & Gas<br />

environment was not present’<br />

project in putting together a unique trailer<br />

loading and off-loading concept to reduce<br />

the overall ground handling times for the<br />

aircraft, ensuring a quick turn-around time<br />

of the An-124. Volga-Dnepr’s technical<br />

capability and loading concepts were a key<br />

factor in it winning the ‘airbridge’ contract<br />

and deugro was able to compliment this<br />

with our specialised hydraulic trailers<br />

specifically imported into PNG to execute<br />

the heavy haul scope of works for the<br />

project.<br />

“deugro’s Technical Engineering<br />

Department worked closely with Volga-<br />

Dnepr’s technical team to formulate a<br />

modular hydraulic trailer-design providing<br />

sufficient incline and deck strength to<br />

successfully create a direct link between<br />

the An-124 ramp and trailer, thereby<br />

eliminating the need for additional ramps<br />

and cranes which ultimately add to the<br />

operational cost, safety risk and turnaround<br />

time per flight.”<br />

Additional work was conducted by the<br />

airline to minimise the empty weight of the<br />

An-124-100 aircraft, tooling and packaging<br />

equipment to maximise the opportunities<br />

offered by the freighter’s cargo capacity<br />

and Volga-Dnepr also developed solutions<br />

to ensure the appropriate maintenance of<br />

aircraft at Port Moresby airport during<br />

the project.<br />

After five years of planning, Volga-Dnepr’s<br />

first An-124 flight touched down on the<br />

new runway at Komo Airfield on May<br />

3rd 2013. A sense of great pride and<br />

achievement was felt by everyone involved<br />

in the project – but this was just the start of<br />

an intensive flying programme.<br />

Over the next 103 days, 88 Volga-Dnepr<br />

An-124 cargo flights safely transported<br />

6,000 tons of equipment and materials that<br />

would help to turn an ambitious project<br />

plan into a reality. For Volga-Dnepr, it was<br />

mission accomplished.<br />

Dennis Gliznoutsa, Vice<br />

President, Development<br />

at Volga-Dnepr Airlines,<br />

said: “This project was<br />

complex and an interesting<br />

logistics challenge and<br />

we are proud to have<br />

worked in partnership<br />

with our colleagues at ExxonMobil and<br />

deugro. Papua New Guinea is a country<br />

that has challenging climatic conditions,<br />

including highlands with frequent fog. We<br />

are proud to have successfully and safely<br />

completed this project by overcoming all<br />

of these difficulties and by once again<br />

demonstrating our expertise in the safe<br />

delivery of unique and outsize cargo. For<br />

us it was not only a commercial project<br />

but the opportunity to test ourselves again.<br />

Participation in this project has also helped<br />

us to strengthen our cooperation with<br />

regular customers and to acquire potential<br />

partners.”<br />

The ‘airbridge’ supplied the main logistics<br />

solution for the Hides Gas Conditioning<br />

Plant in that it allowed the project to<br />

deliver most of the major equipment<br />

required to complete the project by<br />

avoiding the 800km road between Lae<br />

and the plant. The equipment transported<br />

on the An-124-100s included the Main<br />

Compressors, Gas Turbine Generators,<br />

Pressure Vessels, Heat Exchangers and all<br />

of the Equipment Rooms for the process<br />

facility.<br />

In 2014, ExxonMobil will deliver its first gas<br />

supplies to consumers in Asia – proving<br />

once again that by combining the best<br />

human spirit, endeavour and engineering,<br />

there is no logistics challenge that cannot<br />

be overcome.