PALLMANN product guide

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

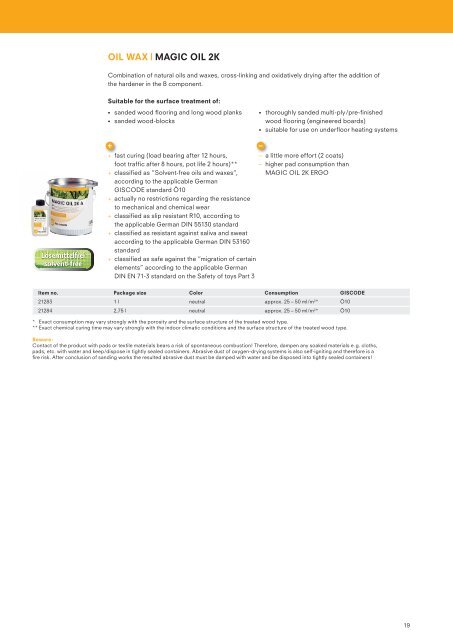

OIL WAX | MAGIC OIL 2K<br />

Combination of natural oils and waxes, cross-linking and oxidatively drying after the addition of<br />

the hardener in the B component.<br />

Suitable for the surface treatment of:<br />

• sanded wood flooring and long wood planks<br />

• sanded wood-blocks<br />

• thoroughly sanded multi-ply /pre-finished<br />

wood flooring (engineered boards)<br />

• suitable for use on underfloor heating systems<br />

Lösemittelfrei<br />

solvent-free<br />

+ fast curing (load bearing after 12 hours,<br />

– a little more effort (2 coats)<br />

foot traffic after 8 hours, pot life 2 hours)** – higher pad consumption than<br />

+ classified as ”Solvent-free oils and waxes”, MAGIC OIL 2K ERGO<br />

according to the applicable German<br />

GISCODE standard Ö10<br />

+ actually no restrictions regarding the resistance<br />

to mechanical and chemical wear<br />

+ classified as slip resistant R10, according to<br />

the applicable German DIN 55130 standard<br />

+ classified as resistant against saliva and sweat<br />

according to the applicable German DIN 53160<br />

standard<br />

+ classified as safe against the ”migration of certain<br />

elements” according to the applicable German<br />

DIN EN 71-3 standard on the Safety of toys Part 3<br />

Item no. Package size Color Consumption GISCODE<br />

21283 1 l neutral approx. 25 – 50 ml/m 2 * Ö10<br />

21284 2,75 l neutral approx. 25 – 50 ml/m 2 * Ö10<br />

* Exact consumption may vary strongly with the porosity and the surface structure of the treated wood type.<br />

** Exact chemical curing time may vary strongly with the indoor climatic conditions and the surface structure of the treated wood type.<br />

Beware:<br />

Contact of the <strong>product</strong> with pads or textile materials bears a risk of spontaneous combustion! Therefore, dampen any soaked materials e. g. cloths,<br />

pads, etc. with water and keep/dispose in tightly sealed containers. Abrasive dust of oxygen-drying systems is also self-igniting and therefore is a<br />

fire risk. After conclusion of sanding works the resulted abrasive dust must be damped with water and be disposed into tightly sealed containers!<br />

19