energy energy saving saving technology technology patented patented

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

<strong>energy</strong> <strong>energy</strong> <strong>saving</strong> <strong>saving</strong> <strong>technology</strong> <strong>technology</strong><br />

<strong>patented</strong> <strong>patented</strong>

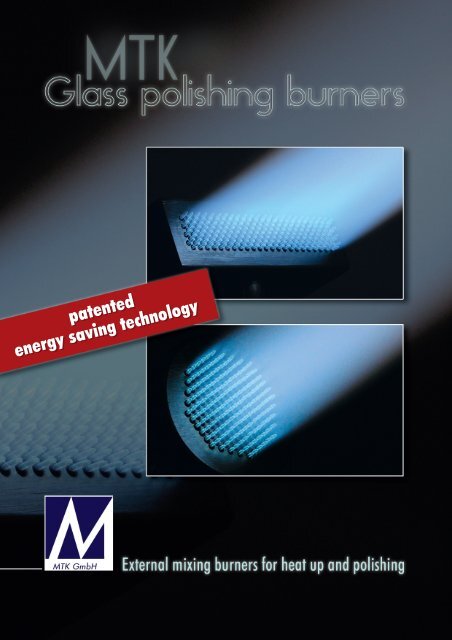

MTK<br />

Glass polishing burners<br />

Patented glass polishing burners for ultimate demands<br />

Quality and precision<br />

Due to a precise distribution of gas inside the MTK burners<br />

there is an extremely homogeneous flame outline and therefore<br />

an equable distribution of temperature. The burner bodies are<br />

made of high-grade steel (V2A) and the front plates exist of<br />

a special heat-resisting material. That is why glass edges and<br />

surfaces of any size can be irradiated and polished in an<br />

environmentally friendly and cost-<strong>saving</strong> way. You do not have<br />

to pay for the expensive use of acid as well as its disposal and<br />

so you are kind to your production costs as well as to the<br />

environment.<br />

Different models<br />

rectangular with a rectangular flame outline<br />

for the use on machines<br />

circular with an octagonal flame outline<br />

for the use on machines<br />

in-line burners, machine burners and mouth<br />

rim burners for the use on a rotary distributor<br />

circular with an octagonal flame outline<br />

for manual operation<br />

individual burners that are produced and<br />

developed on your demands<br />

MTK high efficiency burners<br />

The MTK <strong>energy</strong> <strong>saving</strong> glass polishing burners are specially<br />

designed for high efficiency. The gas consumption has been<br />

reduced by more than 20 % and the lifetime has been<br />

extended significantly. So these burners offer you an additional<br />

<strong>saving</strong> potential in your budget of production.<br />

All MTK burners can be used with natural gas, propane gas or<br />

hydrogen as demanded (each combined with oxygen).<br />

2<br />

MTK Metalltechnik Krapf GmbH | Weidingweg 8 · 92637 Weiden/OPf. | Tel. +49 961 67076 0

MTK<br />

Glass polishing burners<br />

Different connectors at MTK glass polishing burners<br />

Applications and connector types<br />

MTK burners can be used with domestic gas,<br />

propane gas and hydrogen, each combined with<br />

oxygen.<br />

For the assembly on the machine there are four<br />

standard applications (A, B, C, and D, see<br />

pictures below). Customized solutions can be<br />

realized if required.<br />

MTK Metalltechnik Krapf GmbH | Weidingweg 8 · 92637 Weiden/OPf. | Tel. +49 961 67076 0<br />

3

MTK<br />

Glass polishing burners<br />

MTK standard inline burners external mixing principle<br />

MTK high efficiency models have a hole<br />

in hole principle. The inner hole leads<br />

the gas and through the surrounding<br />

gap flows the oxygen. The advantage of<br />

this principle is the permanent cooling<br />

of the gas pipe by the oxygen flow.<br />

The identification of rectangular machine<br />

burners is FW xx for the flame width [mm]<br />

and R x for the number of rows.<br />

MTK standard model E.B.R. 105 (S)<br />

MTK high efficiency model E.B.R.105(HE)<br />

MTK glass polishing burners do all work<br />

with external gas mixing principle.<br />

At the standard types there is the gas<br />

outlet at the small holes and the oxygen<br />

outlet at the wider holes around.<br />

MTK high efficiency model E.B.R.105 (HE)<br />

MTK provides flame width from 25 mm to 200mm and row numbers from 1 to 10.<br />

(other sizes on demand)<br />

4<br />

MTK Metalltechnik Krapf GmbH | Weidingweg 8 · 92637 Weiden/OPf. | Tel. +49 961 67076 0

MTK<br />

Glass polishing burners<br />

Circular burners<br />

MTK circular burners have an octagonal<br />

gas outlet and they show an extremely<br />

regular and homogeneous flame.<br />

Circular or machine burners are available<br />

in standard and high efficiency version.<br />

E.B.M 104 (S)<br />

E.B.M 104 (HE)<br />

E:B.M. 104 (HE) - Flame<br />

We can provide flame<br />

width from 10 to 40mm (customized<br />

sizes on demand)<br />

MTK Metalltechnik Krapf GmbH | Weidingweg 8 · 92637 Weiden/OPf. | Tel. +49 961 67076 0<br />

5

MTK<br />

Glass polishing burners<br />

MTK mouth rim burners<br />

MTK mouth rim burners are particularly<br />

suitable for the inside warming and the<br />

inside polishing of hollow and drinking<br />

glass.<br />

MTK mouth rim burner standard<br />

MTK mouth rim burner with a flame diameter of 30 mm<br />

Mouth rim burner standard 100 mm in use<br />

Mouth rim burners are provided at<br />

different sizes on demand of the customer.<br />

6<br />

MTK Metalltechnik Krapf GmbH | Weidingweg 8 · 92637 Weiden/OPf. | Tel. +49 961 67076 0

MTK<br />

Glass polishing burners<br />

MTK glas polishing burners for manual use<br />

The series of MTK manual burners are<br />

designed for manual operation.<br />

Connection Type B is recommended for<br />

feed pipe connection.<br />

MTK manual burners can either be<br />

provided as standard burner or as high<br />

efficiency version<br />

MTK manual burner E.B.H. 101(S)<br />

MTK manual burner E.B.H. 101 (HE)<br />

Flame MTK manual burner E.B.R. 101 (HE)<br />

We can provide flame<br />

width from 10 to 40mm<br />

(customized sizes on demand)<br />

MTK Metalltechnik Krapf GmbH | Weidingweg 8 · 92637 Weiden/OPf. | Tel. +49 961 67076 0<br />

7

MTK<br />

Glass polishing burners<br />

Customized solutions by MTK<br />

Unique challenges and conditions require<br />

appropriate tools or customized burners.<br />

We manufacture any type of glass<br />

polishing burners according to special<br />

requirements and in agreement with our<br />

customers.<br />

Customized MTK glass polishing burners<br />

will have same high quality as standard<br />

products from MTK.<br />

We reserve the right to make <strong>technology</strong> and design changes in the interest of product improvement.<br />

For further information please visit us at www.mtkgmbh.de .<br />

MTK Metalltechnik Krapf GmbH<br />

Weidingweg 8 · 92637 Weiden/OPf.<br />

Tel. 0049 961 67076 0<br />

Mail info@mtkgmbh.de<br />

www.mtkgmbh.de<br />

8<br />

MTK Metalltechnik Krapf GmbH | Weidingweg 8 · 92637 Weiden/OPf. | Tel. +49 961 67076 0