Milk Production Control of Quality and Safety in

Milk Production Control of Quality and Safety in

Milk Production Control of Quality and Safety in

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

The Organic HACCP Project leaflets<br />

This is no. 7 <strong>of</strong> a series <strong>of</strong> 14 leaflets compris<strong>in</strong>g <strong>in</strong>formation<br />

on how control <strong>of</strong> quality <strong>and</strong> safety can be further improved<br />

<strong>in</strong> organic supply cha<strong>in</strong>s across Europe. The Organic<br />

HACCP project has reviewed studies <strong>of</strong> consumer concerns<br />

<strong>and</strong> preferences <strong>in</strong> relation to organic production systems<br />

<strong>and</strong> collected <strong>in</strong>formation about typical production cha<strong>in</strong>s for<br />

7 commodities <strong>in</strong> regions across Europe. For each <strong>of</strong> the<br />

criteria listed below, the <strong>in</strong>formation was analysed to identify<br />

Critical <strong>Control</strong> Po<strong>in</strong>ts (CCPs), def<strong>in</strong>ed as the steps <strong>in</strong> supply<br />

cha<strong>in</strong>s where the qualities <strong>of</strong> the f<strong>in</strong>al product can be<br />

controlled most efficiently. CCPs were identified us<strong>in</strong>g<br />

methods developed for Hazard Analysis by Critical <strong>Control</strong><br />

Po<strong>in</strong>ts (HACCP), a st<strong>and</strong>ard procedure to prevent food<br />

safety risks. The new aspect is thus to improve how consumer<br />

concerns are addressed, through the use <strong>of</strong> the CCP<br />

concept for a wide range <strong>of</strong> criteria, not only safety: 1. Microbial<br />

tox<strong>in</strong>s <strong>and</strong> abiotic contam<strong>in</strong>ants; 2. Potential pathogens;<br />

3. Natural plant toxicants; 4. Freshness <strong>and</strong> taste; 5.<br />

Nutrient content <strong>and</strong> food additives; 6. Fraud; 7. Social <strong>and</strong><br />

ethical aspects.<br />

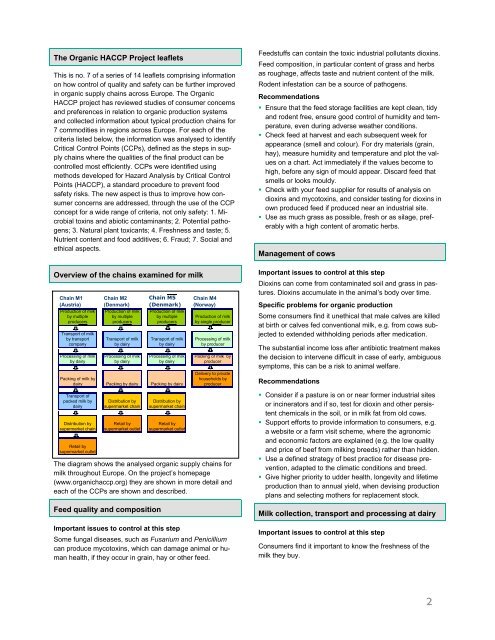

Overview <strong>of</strong> the cha<strong>in</strong>s exam<strong>in</strong>ed for milk<br />

Cha<strong>in</strong> M1<br />

(Austria)<br />

<strong>Production</strong> <strong>of</strong> milk<br />

by multiple<br />

producers<br />

Transport <strong>of</strong> milk<br />

by transport<br />

company<br />

Process<strong>in</strong>g <strong>of</strong> milk<br />

by dairy<br />

Cha<strong>in</strong> M2<br />

(Denmark)<br />

<strong>Production</strong> <strong>of</strong> milk<br />

by multiple<br />

producers<br />

Transport <strong>of</strong> milk<br />

by dairy<br />

Process<strong>in</strong>g <strong>of</strong> milk<br />

by dairy<br />

The diagram shows the analysed organic supply cha<strong>in</strong>s for<br />

milk throughout Europe. On the project’s homepage<br />

(www.organichaccp.org) they are shown <strong>in</strong> more detail <strong>and</strong><br />

each <strong>of</strong> the CCPs are shown <strong>and</strong> described.<br />

Feed quality <strong>and</strong> composition<br />

Cha<strong>in</strong> M5<br />

(Denmark)<br />

<strong>Production</strong> <strong>of</strong> milk<br />

by multiple<br />

producers<br />

Transport <strong>of</strong> milk<br />

by dairy<br />

Process<strong>in</strong>g <strong>of</strong> milk<br />

by dairy<br />

Pack<strong>in</strong>g <strong>of</strong> milk by<br />

dairy Pack<strong>in</strong>g by dairy Pack<strong>in</strong>g by dairy<br />

Transport <strong>of</strong><br />

packed milk by<br />

dairy<br />

Distribution by<br />

supermarket cha<strong>in</strong><br />

Retail by<br />

supermarket outlet<br />

Distribution by<br />

supermarket cha<strong>in</strong><br />

Retail by<br />

supermarket outlet<br />

Distribution by<br />

supermarket cha<strong>in</strong><br />

Retail by<br />

supermarket outlet<br />

Cha<strong>in</strong> M4<br />

(Norway)<br />

<strong>Production</strong> <strong>of</strong> milk<br />

by s<strong>in</strong>gle producer<br />

Process<strong>in</strong>g <strong>of</strong> milk<br />

by producer<br />

Pack<strong>in</strong>g <strong>of</strong> milk by<br />

producer<br />

Delivery to private<br />

households by<br />

producer<br />

Important issues to control at this step<br />

Some fungal diseases, such as Fusarium <strong>and</strong> Penicillium<br />

can produce mycotox<strong>in</strong>s, which can damage animal or human<br />

health, if they occur <strong>in</strong> gra<strong>in</strong>, hay or other feed.<br />

Feedstuffs can conta<strong>in</strong> the toxic <strong>in</strong>dustrial pollutants diox<strong>in</strong>s.<br />

Feed composition, <strong>in</strong> particular content <strong>of</strong> grass <strong>and</strong> herbs<br />

as roughage, affects taste <strong>and</strong> nutrient content <strong>of</strong> the milk.<br />

Rodent <strong>in</strong>festation can be a source <strong>of</strong> pathogens.<br />

Recommendations<br />

Ensure that the feed storage facilities are kept clean, tidy<br />

<strong>and</strong> rodent free, ensure good control <strong>of</strong> humidity <strong>and</strong> temperature,<br />

even dur<strong>in</strong>g adverse weather conditions.<br />

Check feed at harvest <strong>and</strong> each subsequent week for<br />

appearance (smell <strong>and</strong> colour). For dry materials (gra<strong>in</strong>,<br />

hay), measure humidity <strong>and</strong> temperature <strong>and</strong> plot the values<br />

on a chart. Act immediately if the values become to<br />

high, before any sign <strong>of</strong> mould appear. Discard feed that<br />

smells or looks mouldy.<br />

Check with your feed supplier for results <strong>of</strong> analysis on<br />

diox<strong>in</strong>s <strong>and</strong> mycotox<strong>in</strong>s, <strong>and</strong> consider test<strong>in</strong>g for diox<strong>in</strong>s <strong>in</strong><br />

own produced feed if produced near an <strong>in</strong>dustrial site.<br />

Use as much grass as possible, fresh or as silage, preferably<br />

with a high content <strong>of</strong> aromatic herbs.<br />

Management <strong>of</strong> cows<br />

Important issues to control at this step<br />

Diox<strong>in</strong>s can come from contam<strong>in</strong>ated soil <strong>and</strong> grass <strong>in</strong> pastures.<br />

Diox<strong>in</strong>s accumulate <strong>in</strong> the animal’s body over time.<br />

Specific problems for organic production<br />

Some consumers f<strong>in</strong>d it unethical that male calves are killed<br />

at birth or calves fed conventional milk, e.g. from cows subjected<br />

to extended withhold<strong>in</strong>g periods after medication.<br />

The substantial <strong>in</strong>come loss after antibiotic treatment makes<br />

the decision to <strong>in</strong>tervene difficult <strong>in</strong> case <strong>of</strong> early, ambiguous<br />

symptoms, this can be a risk to animal welfare.<br />

Recommendations<br />

Consider if a pasture is on or near former <strong>in</strong>dustrial sites<br />

or <strong>in</strong>c<strong>in</strong>erators <strong>and</strong> if so, test for diox<strong>in</strong> <strong>and</strong> other persistent<br />

chemicals <strong>in</strong> the soil, or <strong>in</strong> milk fat from old cows.<br />

Support efforts to provide <strong>in</strong>formation to consumers, e.g.<br />

a website or a farm visit scheme, where the agronomic<br />

<strong>and</strong> economic factors are expla<strong>in</strong>ed (e.g. the low quality<br />

<strong>and</strong> price <strong>of</strong> beef from milk<strong>in</strong>g breeds) rather than hidden.<br />

Use a def<strong>in</strong>ed strategy <strong>of</strong> best practice for disease prevention,<br />

adapted to the climatic conditions <strong>and</strong> breed.<br />

Give higher priority to udder health, longevity <strong>and</strong> lifetime<br />

production than to annual yield, when devis<strong>in</strong>g production<br />

plans <strong>and</strong> select<strong>in</strong>g mothers for replacement stock.<br />

<strong>Milk</strong> collection, transport <strong>and</strong> process<strong>in</strong>g at dairy<br />

Important issues to control at this step<br />

Consumers f<strong>in</strong>d it important to know the freshness <strong>of</strong> the<br />

milk they buy.<br />

2