Sievmaster Segregator

Sievmaster Segregator

Sievmaster Segregator

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

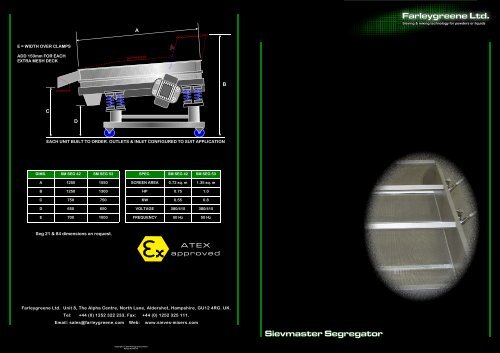

A<br />

Sieving & mixing technology for powders or liquids<br />

E = WIDTH OVER CLAMPS<br />

ADD 150mm FOR EACH<br />

EXTRA MESH DECK<br />

B<br />

C<br />

D<br />

EACH UNIT BUILT TO ORDER. OUTLETS & INLET CONFIGURED TO SUIT APPLICATION<br />

DIMS. SM SEG 42 SM SEG 53<br />

A 1250 1550<br />

B 1250 1300<br />

C 750 750<br />

D 650 650<br />

E 700 1000<br />

Seg 21 & 84 dimensions on request.<br />

SPEC. SM SEG 42 SM SEG 53<br />

SCREEN AREA 0.72 sq. m 1.35 sq. m<br />

HP 0.75 1.0<br />

KW 0.55 0.8<br />

VOLTAGE 380/415 380/415<br />

FREQUENCY 50 Hz 50 Hz<br />

Other voltages & frequencies available on request<br />

ATEX versions available<br />

A T E X<br />

a p p r o v e d<br />

Farleygreene Ltd. Unit 8, The Alpha Centre, North Lane, Aldershot, Hampshire, GU12 4RG. UK.<br />

Tel: +44 (0) 1252 322 233. Fax: +44 (0) 1252 325 111.<br />

Email: sales@farleygreene.com Web: www.sieves-mixers.com<br />

Copyright © 2006 Farleygreene Limited<br />

Design by Ant.FG

The ‘<strong>Sievmaster</strong> <strong>Segregator</strong>’ range of machines are suitable for separating both wet or dry products. The large screen<br />

area allows the product prolonged sieving time and the unique sealed linear vibration system gently but positively presents<br />

the product to the mesh to ensure the material is efficiently screened. This unit is ideally suited to light fragile products<br />

with low bulk densities. When sieving liquids or wet products the adjustable screen inclination can be positioned to retain<br />

the liquid, the oversize particulate is then driven forward for collection. This system is self cleaning and overcomes the basic<br />

problem of liquid ‘carryover’ in the solids. A ‘Hygiene’ series is also available, developed especially for the food industry.<br />

It is manufactured entirely from stainless steel. These easy clean units can be supplied upon wheels for mobility or feet<br />

for static installations. The range is available with variations to provide up to four separations, with a wide choice of sieving<br />

aids for problem materials.<br />

Typical uses<br />

Advantages<br />

Options<br />

Check sieving ingredients<br />

Under FIBC/IBC discharging systems<br />

Dedusting, dewatering of products<br />

Pharmaceutical powders<br />

Wet or Dry applications<br />

Liquid separation<br />

Tablets & Capsules<br />

Flour, Sugar, Spices, Cosmetics, Seeds,<br />

almost any powder or granulated material<br />

Your product quality maintained<br />

Sieve and convey in one action<br />

FDA approved materials of construction<br />

Low maintenance/running costs<br />

Quick change bonded screens<br />

Dust & hose proof<br />

Easy clean design, no crevices<br />

Meets HACCP, BRC audit requirements<br />

Noise level less than 70 dBA in use<br />

Available in 2 x 1, 4 x 2, 5 x 3 & 8 x 4 foot beds<br />

Mobile stands for greater flexibility<br />

Designed specifically for your application<br />

Oversize discharging outlet<br />

Ultrasonic deblinding<br />

Vacuum transfer model<br />

Thru’ wall model for transfer to high risk areas<br />

Full validation packages for Food/Pharma<br />

ATEX approval on all sizes