Workshop Brochure - Society of Petroleum Engineers

Workshop Brochure - Society of Petroleum Engineers

Workshop Brochure - Society of Petroleum Engineers

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

WORKSHOP<br />

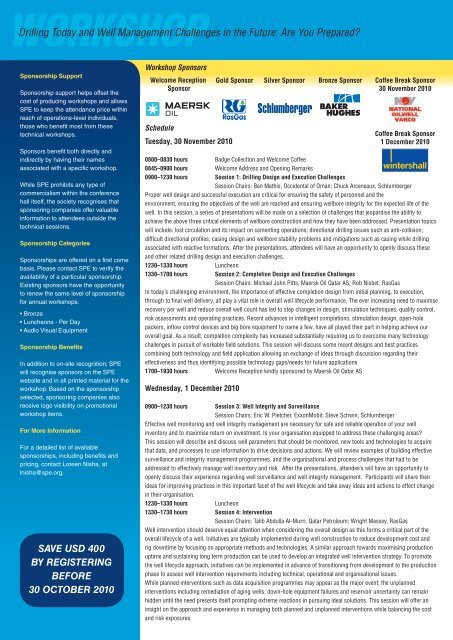

Drilling Today and Well Management Challenges in the Future: Are You Prepared?<br />

Sponsorship Support<br />

Sponsorship support helps <strong>of</strong>fset the<br />

cost <strong>of</strong> producing workshops and allows<br />

SPE to keep the attendance price within<br />

reach <strong>of</strong> operations-level individuals,<br />

those who benefit most from these<br />

technical workshops.<br />

Sponsors benefit both directly and<br />

indirectly by having their names<br />

associated with a specific workshop.<br />

While SPE prohibits any type <strong>of</strong><br />

commercialism within the conference<br />

hall itself, the society recognises that<br />

sponsoring companies <strong>of</strong>fer valuable<br />

information to attendees outside the<br />

technical sessions.<br />

Sponsorship Categories<br />

Sponsorships are <strong>of</strong>fered on a first come<br />

basis. Please contact SPE to verify the<br />

availability <strong>of</strong> a particular sponsorship.<br />

Existing sponsors have the opportunity<br />

to renew the same level <strong>of</strong> sponsorship<br />

for annual workshops.<br />

• Bronze<br />

• Luncheons - Per Day<br />

• Audio Visual Equipment<br />

Sponsorship Benefits<br />

In addition to on-site recognition; SPE<br />

will recognise sponsors on the SPE<br />

website and in all printed material for the<br />

workshop. Based on the sponsorship<br />

selected, sponsoring companies also<br />

receive logo visibility on promotional<br />

workshop items.<br />

For More Information<br />

For a detailed list <strong>of</strong> available<br />

sponsorships, including benefits and<br />

pricing, contact Loreen Nisha, at<br />

lnisha@spe.org.<br />

SAVE USD 400<br />

BY REGISTERING<br />

BEFORE<br />

30 OCTOBER 2010<br />

<strong>Workshop</strong> Sponsors<br />

Welcome Reception<br />

Sponsor<br />

Schedule<br />

Tuesday, 30 November 2010<br />

0800–0830 hours Badge Collection and Welcome C<strong>of</strong>fee<br />

0845–0900 hours Welcome Address and Opening Remarks<br />

0900–1230 hours Session 1: Drilling Design and Execution Challenges<br />

Session Chairs: Ben Mathis, Occidental <strong>of</strong> Oman; Chuck Arceneaux, Schlumberger<br />

Proper well design and successful execution are critical for ensuring the safety <strong>of</strong> personnel and the<br />

environment, ensuring the objectives <strong>of</strong> the well are reached and ensuring wellbore integrity for the expected life <strong>of</strong> the<br />

well. In this session, a series <strong>of</strong> presentations will be made on a selection <strong>of</strong> challenges that jeopardise the ability to<br />

achieve the above three critical elements <strong>of</strong> wellbore construction and how they have been addressed. Presentation topics<br />

will include: lost circulation and its impact on cementing operations; directional drilling issues such as anti-collision;<br />

difficult directional pr<strong>of</strong>iles; casing design and wellbore stability problems and mitigations such as casing while drilling<br />

associated with reactive formations. After the presentations, attendees will have an opportunity to openly discuss these<br />

and other related drilling design and execution challenges.<br />

1230–1330 hours Luncheon<br />

1330–1700 hours Session 2: Completion Design and Execution Challenges<br />

Session Chairs: Michael John Pitts, Maersk Oil Qatar AS; Rob Nisbet, RasGas<br />

In today’s challenging environment, the importance <strong>of</strong> effective completion design from initial planning, to execution,<br />

through to final well delivery, all play a vital role in overall well lifecycle performance. The ever increasing need to maximse<br />

recovery per well and reduce overall well count has led to step changes in design, stimulation techniques, quality control,<br />

risk assessments and operating practices. Recent advances in intelligent completions, stimulation design, open-hole<br />

packers, inflow control devices and big bore equipment to name a few, have all played their part in helping achieve our<br />

overall goal. As a result, completion complexity has increased substantially requiring us to overcome many technology<br />

challenges in pursuit <strong>of</strong> workable field solutions. This session will discuss some recent designs and best practices<br />

combining both technology and field application allowing an exchange <strong>of</strong> ideas through discussion regarding their<br />

effectiveness and thus identifying possible technology gaps/needs for future applications.<br />

1700–1930 hours Welcome Reception kindly sponsored by Maersk Oil Qatar AS<br />

Wednesday, 1 December 2010<br />

Gold Sponsor Silver Sponsor Bronze Sponsor<br />

C<strong>of</strong>fee Break Sponsor<br />

30 November 2010<br />

C<strong>of</strong>fee Break Sponsor<br />

1 December 2010<br />

0900–1230 hours Session 3: Well Integrity and Surveillance<br />

Session Chairs: Eric W. Pletcher, ExxonMobil; Steve Schwin, Schlumberger<br />

Effective well monitoring and well integrity management are necessary for safe and reliable operation <strong>of</strong> your well<br />

inventory and to maximise return on investment. Is your organisation equipped to address these challenging areas?<br />

This session will describe and discuss well parameters that should be monitored, new tools and technologies to acquire<br />

that data, and processes to use information to drive decisions and actions. We will review examples <strong>of</strong> building effective<br />

surveillance and integrity management programmes, and the organisational and process challenges that had to be<br />

addressed to effectively manage well inventory and risk. After the presentations, attendee’s will have an opportunity to<br />

openly discuss their experience regarding well surveillance and well integrity management. Participants will share their<br />

ideas for improving practices in this important facet <strong>of</strong> the well lifecycle and take away ideas and actions to effect change<br />

in their organisation.<br />

1230–1330 hours Luncheon<br />

1330–1730 hours Session 4: Intervention<br />

Session Chairs: Talib Abdulla Al-Murri, Qatar <strong>Petroleum</strong>; Wright Massey, RasGas<br />

Well intervention should deserve equal attention when considering the overall design as this forms a critical part <strong>of</strong> the<br />

overall lifecycle <strong>of</strong> a well. Initiatives are typically implemented during well construction to reduce development cost and<br />

rig downtime by focusing on appropriate methods and technologies. A similar approach towards maximising production<br />

uptime and sustaining long term production can be used to develop an integrated well intervention strategy. To promote<br />

the well lifecycle approach, initiatives can be implemented in advance <strong>of</strong> transitioning from development to the production<br />

phase to assess well intervention requirements including technical, operational and organisational issues.<br />

While planned interventions such as data acquisition programmes may appear as the major event; the unplanned<br />

interventions including remediation <strong>of</strong> aging wells, down-hole equipment failures and reservoir uncertainty can remain<br />

hidden until the need presents itself prompting extreme reactions in pursuing ideal solutions. This session will <strong>of</strong>fer an<br />

insight on the approach and experience in managing both planned and unplanned interventions while balancing the cost<br />

and risk exposures.