automated finished goods warehouse for laminate ... - SSI Schäfer

automated finished goods warehouse for laminate ... - SSI Schäfer

automated finished goods warehouse for laminate ... - SSI Schäfer

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

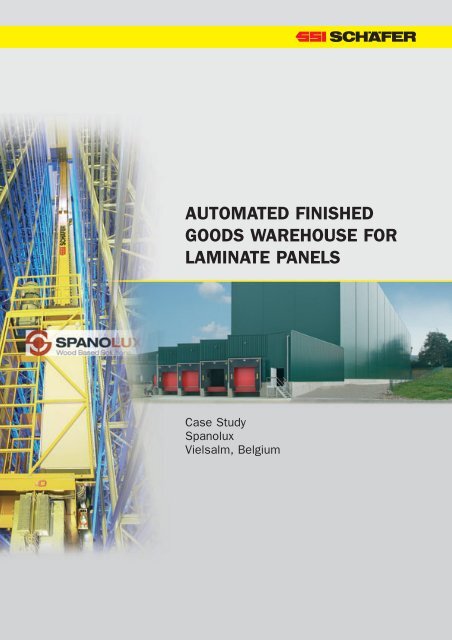

AUTOMATED FINISHED<br />

GOODS WAREHOUSE FOR<br />

LAMINATE PANELS<br />

Case Study<br />

Spanolux<br />

Vielsalm, Belgium

PROJECT SPANOLUX, BELGIUM<br />

Project objective<br />

Increase in storage capacity<br />

Reduction of internal handling and<br />

process costs<br />

Disintegration of block storage areas<br />

Centralization of the shipping area<br />

Rasche Auftragsabwicklung bei hoher Produktdichte im K-Pemat<br />

Our scope of supply and services:<br />

Project management<br />

Roof and wall<br />

Racking system<br />

Sprinkler<br />

Pallet conveyor system<br />

Storage and retrieval machines (SRM)<br />

Warehouse management and control systems<br />

Storage and retrieval machine storing a pallet<br />

High bay <strong>warehouse</strong> (HBW)<br />

L x W x H<br />

115 x 24 x 27 m<br />

Loading aids<br />

EURO and one waypallets<br />

(similar to EURO)<br />

Storage locations 18,000<br />

Weight<br />

950 kg<br />

Type of storage double-deep<br />

Storage and retrieval machine (SRM)<br />

Quantity SRM / aisles 3 / 3<br />

Load-carrying device Telescopic <strong>for</strong>k<br />

Traveling speed 190 m/min.<br />

Lifting speed<br />

60 m/min.<br />

Throughput<br />

(per SRM)<br />

3 x 28.8 DC/h<br />

3 x 46.5 SC/h<br />

Incoming <strong>goods</strong> from the production: transfer onto the conveyor using a front <strong>for</strong>klift or an<br />

<strong>automated</strong> guided vehicle

PROJECT SPANOLUX, BELGIUM<br />

Automatic high-rise rack<br />

replaces block storage<br />

Spanolux MDF started production in the Belgian<br />

town of Vielslam only in 1997 and is the first and<br />

only Belgian MDF plant.<br />

Hence, it is a new enterprise that is striving <strong>for</strong><br />

perfection in the MDF process.<br />

The great entrepreneurial success can be seen in<br />

a permanently and strongly increasing production<br />

volume as well as continually growing sales.<br />

Eventually, full <strong>warehouse</strong>s with conventional block<br />

storage and low throughput were the trigger <strong>for</strong> the<br />

planning and construction of a modern high bay<br />

<strong>warehouse</strong> with aisle-bound storage and retrieval<br />

machines.<br />

With regard to finding a concept, detailed planning,<br />

and the implementation of the project, <strong>SSI</strong> Schäfer<br />

proved to be a competent partner.<br />

The buffer <strong>for</strong> <strong>finished</strong> <strong>goods</strong> – a three-aisle highbay<br />

<strong>warehouse</strong> with one storage and retrieval<br />

machine per rack aisle – was integrated into the<br />

logistics processes<br />

A buffer line (chain conveyor) over the entire rack length decouples production and <strong>warehouse</strong><br />

Pallet conveyor system<br />

Components Roller conveyor<br />

Lifting transfer unit<br />

Triple-strand chain conveyor<br />

Four pallet shuttle vehicle<br />

Control station (shape<br />

control, scales, scanner)<br />

Warehouse management system<br />

Computer hardware HP Proliant DL 380<br />

generation 4 packaged<br />

cluster MSA 500 G2<br />

Operating system Microsoft<br />

Windows 2000 server<br />

Database system Oracle 9i, standard edition<br />

WMS software<br />

A double shuttle vehicle suitable <strong>for</strong> the transport of a total of four pallets ensures high per<strong>for</strong>mance<br />

<strong>for</strong> parallel storage and retrieval operations<br />

Functionalities<br />

Warehouse management<br />

Goods receiving / shipping<br />

Order picking<br />

Material flow control<br />

Visualization<br />

Shape control, pallet identification, and weight check at the control station

General contracting<br />

Planning and consulting<br />

Warehouse management system<br />

Control systems<br />

Steel structure / racking systems<br />

Storage and retrieval machines<br />

Conveyor systems<br />

Service and maintenance<br />

No. 130206en, © by <strong>SSI</strong> Schäfer Giebelstadt. Printed in Germany.<br />

Any liability <strong>for</strong> misprints excluded. Translation: Manuela Ellebruch.<br />

<strong>SSI</strong> Schäfer Noell GmbH i_Park Klingholz 18/19<br />

D-97232 Giebelstadt<br />

Phone: +49/93 34/979-0<br />

Fax: +49/93 34/979-100<br />

www.ssi-schaefer-noell.com<br />

info@ssi-schaefer-noell.com