OCEAN GUARD BWMS

Ocean Guard BWMS has been certified by IMO, DNV (full scale type approval), AMS-USCG and many other classes and so on. Our product is of small footprint, low operation cost, less maintenance, simple and neat structure and excellent sterlization. We have sold around 210 shipsets of BWMS system, and many are already installed and in good operation. Please kindly find the enclosed brochure of us as attached. If you need more inforamtion about our product, please find as below or feel free to contact us. - Treatment ONLY DURING BALLASTING. No treatment is needed during de-ballasting thus making possible the gravity de-ballasting operation. - Very small power consumption. Please also note that in the extreme case that the system will work in completely fresh water, the power consumption will only rise up at 30%, while its effectiveness will not be affected. - Very small footprint. - Very low maintenance cost. The system does not use any chemicals or additives for its operation, while it will need very few spare parts, which are the following: Filter elements that have approximately 5-10 years lifespan. Ultrasound generator that has approximately 5 years lifespan. Sensors that have approximately 5 years lifespan. - Very low operational cost. Please note that the operational cost to treat 1 m3 of ballast water is less than USD 0,02 (including energy cost, spare parts, maintenance, etc.) - No special maintenance needed by the crew. The system is self-cleaning by means of ultrasound generator. There will probably be annual survey or every two years required by Class, for which HEADWAY can go on board to check and certify the system and its operational parameters. - Long lifespan. The EUT catalytic material, which is the core and the most important part of the system, is guaranteed for the lifespan of the vessel. - OceanGuard does not affect the ballast tank coatings. - No dangerous byproducts. There are no gases or any other dangerous byproducts produced (i.e. H2, O3). - Approvals. OceanGuard has the following approvals: USCG AMS acceptance DNV type approval IMO basic approval IMO final approval CCS type approval BV type approval

Ocean Guard BWMS has been certified by IMO, DNV (full scale type approval), AMS-USCG and many other classes and so on. Our product is of small footprint, low operation cost, less maintenance, simple and neat structure and excellent sterlization. We have sold around 210 shipsets of BWMS system, and many are already installed and in good operation.

Please kindly find the enclosed brochure of us as attached.

If you need more inforamtion about our product, please find as below or feel free to contact us.

- Treatment ONLY DURING BALLASTING. No treatment is needed during de-ballasting thus making possible the gravity de-ballasting operation.

- Very small power consumption. Please also note that in the extreme case that the system will work in completely fresh water, the power consumption will only rise up at 30%, while its effectiveness will not be affected.

- Very small footprint.

- Very low maintenance cost. The system does not use any chemicals or additives for its operation, while it will need very few spare parts, which are the following:

Filter elements that have approximately 5-10 years lifespan.

Ultrasound generator that has approximately 5 years lifespan.

Sensors that have approximately 5 years lifespan.

- Very low operational cost. Please note that the operational cost to treat 1 m3 of ballast water is less than USD 0,02 (including energy cost, spare parts, maintenance, etc.)

- No special maintenance needed by the crew. The system is self-cleaning by means of ultrasound generator. There will probably be annual survey or every two years required by Class, for which HEADWAY can go on board to check and certify the system and its operational parameters.

- Long lifespan. The EUT catalytic material, which is the core and the most important part of the system, is guaranteed for the lifespan of the vessel.

- OceanGuard does not affect the ballast tank coatings.

- No dangerous byproducts. There are no gases or any other dangerous byproducts produced (i.e. H2, O3).

- Approvals. OceanGuard has the following approvals:

USCG AMS acceptance

DNV type approval

IMO basic approval

IMO final approval

CCS type approval

BV type approval

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

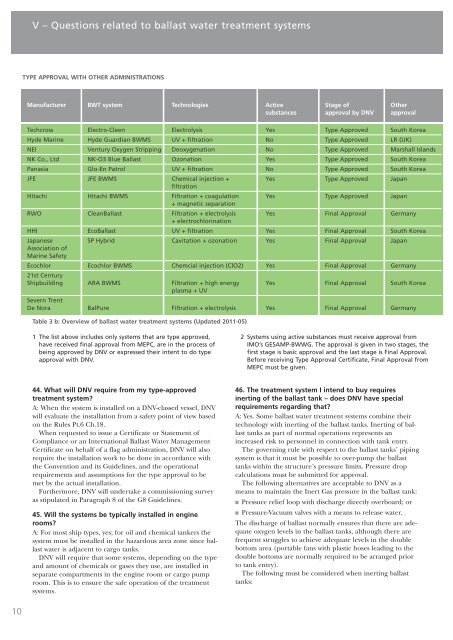

V – Questions related to ballast water treatment systems<br />

TYPE APPROVAL WITH OTHER ADMINISTRATIONS<br />

Manufacturer BWT system Technologies Active Stage of Other<br />

substances approval by DNV approval<br />

Techcross Electro-Cleen Electrolysis Yes Type Approved South Korea<br />

Hyde Marine Hyde Guardian <strong>BWMS</strong> UV + filtration No Type Approved LR (UK)<br />

NEI Ventury Oxygen Stripping Deoxygenation No Type Approved Marshall Islands<br />

NK Co., Ltd NK-O3 Blue Ballast Ozonation Yes Type Approved South Korea<br />

Panasia Glo-En Patrol UV + filtration No Type Approved South Korea<br />

JFE JFE <strong>BWMS</strong> Chemical injection + Yes Type Approved Japan<br />

filtration<br />

Hitachi Hitachi <strong>BWMS</strong> Filtration + coagulation Yes Type Approved Japan<br />

+ magnetic separation<br />

RWO CleanBallast Filtration + electrolysis Yes Final Approval Germany<br />

+ electrochlorination<br />

HHI EcoBallast UV + filtration Yes Final Approval South Korea<br />

Japanese SP Hybrid Cavitation + ozonation Yes Final Approval Japan<br />

Association of<br />

Marine Safety<br />

Ecochlor Ecochlor <strong>BWMS</strong> Chemcial injection (ClO2) Yes Final Approval Germany<br />

21st Century<br />

Shipbuilding ARA <strong>BWMS</strong> Filtration + high energy Yes Final Approval South Korea<br />

plasma + UV<br />

Severn Trent<br />

De Nora BalPure Filtration + electrolysis Yes Final Approval Germany<br />

Table 3 b: Overview of ballast water treatment systems (Updated 2011-05)<br />

1 The list above includes only systems that are type approved,<br />

have received final approval from MEPC, are in the process of<br />

being approved by DNV or expressed their intent to do type<br />

approval with DNV.<br />

2 Systems using active substances must receive approval from<br />

IMO’s GESAMP-BWWG. The approval is given in two stages, the<br />

first stage is basic approval and the last stage is Final Approval.<br />

Before receiving Type Approval Certificate, Final Approval from<br />

MEPC must be given.<br />

44. What will DNV require from my type-approved<br />

treatment system?<br />

A: When the system is installed on a DNV-classed vessel, DNV<br />

will evaluate the installation from a safety point of view based<br />

on the Rules Pt.6 Ch.18.<br />

When requested to issue a Certificate or Statement of<br />

Compliance or an International Ballast Water Management<br />

Certificate on behalf of a flag administration, DNV will also<br />

require the installation work to be done in accordance with<br />

the Convention and its Guidelines, and the operational<br />

requirements and assumptions for the type approval to be<br />

met by the actual installation.<br />

Furthermore, DNV will undertake a commissioning survey<br />

as stipulated in Paragraph 8 of the G8 Guidelines.<br />

45. Will the systems be typically installed in engine<br />

rooms?<br />

A: For most ship types, yes; for oil and chemical tankers the<br />

system must be installed in the hazardous area zone since ballast<br />

water is adjacent to cargo tanks.<br />

DNV will require that some systems, depending on the type<br />

and amount of chemicals or gases they use, are installed in<br />

separate compartments in the engine room or cargo pump<br />

room. This is to ensure the safe operation of the treatment<br />

systems.<br />

46. The treatment system I intend to buy requires<br />

inerting of the ballast tank – does DNV have special<br />

requirements regarding that?<br />

A: Yes. Some ballast water treatment systems combine their<br />

technology with inerting of the ballast tanks. Inerting of ballast<br />

tanks as part of normal operations represents an<br />

increased risk to personnel in connection with tank entry.<br />

The governing rule with respect to the ballast tanks’ piping<br />

system is that it must be possible to over-pump the ballast<br />

tanks within the structure’s pressure limits. Pressure drop<br />

calculations must be submitted for approval.<br />

The following alternatives are acceptable to DNV as a<br />

means to maintain the Inert Gas pressure in the ballast tank:<br />

■ Pressure relief loop with discharge directly overboard; or<br />

■ Pressure-Vacuum valves with a means to release water.<br />

The discharge of ballast normally ensures that there are adequate<br />

oxygen levels in the ballast tanks, although there are<br />

frequent struggles to achieve adequate levels in the double<br />

bottom area (portable fans with plastic hoses leading to the<br />

double bottoms are normally required to be arranged prior<br />

to tank entry).<br />

The following must be considered when inerting ballast<br />

tanks:<br />

10