scissors - Rocket Medical plc

scissors - Rocket Medical plc

scissors - Rocket Medical plc

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

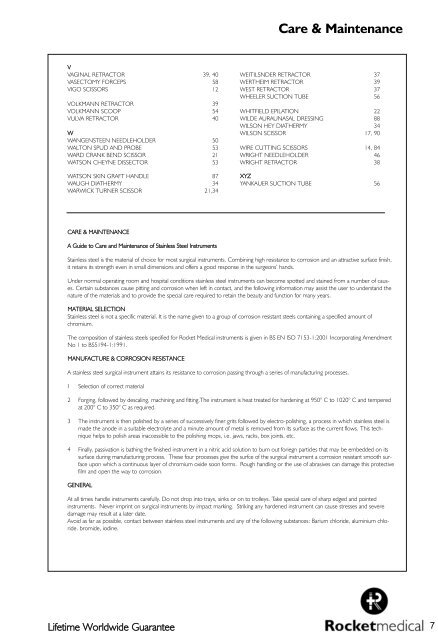

Care & Maintenance<br />

V<br />

VAGINAL RETRACTOR 39, 40 WEITILSNDER RETRACTOR 37<br />

VASECTOMY FORCEPS 58 WERTHEIM RETRACTOR 39<br />

VIGO SCISSORS 12 WEST RETRACTOR 37<br />

WHEELER SUCTION TUBE 56<br />

VOLKMANN RETRACTOR 39<br />

VOLKMANN SCOOP 54 WHITFIELD EPILATION 22<br />

VULVA RETRACTOR 40 WILDE AURAUNASAL DRESSING 88<br />

WILSON HEY DIATHERMY 34<br />

W WILSON SCISSOR 17, 90<br />

WANGENSTEEN NEEDLEHOLDER 50<br />

WALTON SPUD AND PROBE 53 WIRE CUTTING SCISSORS 14, 84<br />

WARD CRANK BEND SCISSOR 21 WRIGHT NEEDLEHOLDER 46<br />

WATSON CHEYNE DISSECTOR 53 WRIGHT RETRACTOR 38<br />

WATSON SKIN GRAFT HANDLE 87 XYZ<br />

WAUGH DIATHERMY 34 YANKAUER SUCTION TUBE 56<br />

WARWICK TURNER SCISSOR 21,34<br />

CARE & MAINTENANCE<br />

A Guide to Care and Maintenance of Stainless Steel Instruments<br />

Stainless steel is the material of choice for most surgical instruments. Combining high resistance to corrosion and an attractive surface finish,<br />

it retains its strength even in small dimensions and offers a good response in the surgeons’ hands.<br />

Under normal operating room and hospital conditions stainless steel instruments can become spotted and stained from a number of causes.<br />

Certain substances cause pitting and corrosion when left in contact, and the following information may assist the user to understand the<br />

nature of the materials and to provide the special care required to retain the beauty and function for many years.<br />

MATERIAL SELECTION<br />

Stainless steel is not a specific material. It is the name given to a group of corrosion resistant steels containing a specified amount of<br />

chromium.<br />

The composition of stainless steels specified for <strong>Rocket</strong> <strong>Medical</strong> instruments is given in BS EN ISO 7153-1:2001 Incorporating Amendment<br />

No 1 to BS5194-1:1991.<br />

MANUFACTURE & CORROSION RESISTANCE<br />

A stainless steel surgical instrument attains its resistance to corrosion passing through a series of manufacturing processes.<br />

I<br />

Selection of correct material<br />

2 Forging, followed by descaling, machining and fitting.The instrument is heat treated for hardening at 950° C to 1020° C and tempered<br />

at 200° C to 350° C as required.<br />

3 The instrument is then polished by a series of successively finer grits followed by electro-polishing, a process in which stainless steel is<br />

made the anode in a suitable electrolyte and a minute amount of metal is removed from its surface as the current flows. This technique<br />

helps to polish areas inaccessible to the polishing mops, i.e. jaws, racks, box joints, etc.<br />

4 Finally, passivation is bathing the finished instrument in a nitric acid solution to burn out foriegn particles that may be embedded on its<br />

surface during manufacturing process. These four processes give the surfce of the surgical instrument a corrosion resistant smooth surface<br />

upon which a continuous layer of chromium oxide soon forms. Rough handling or the use of abrasives can damage this protective<br />

film and open the way to corrosion.<br />

GENERAL<br />

At all times handle instruments carefully. Do not drop into trays, sinks or on to trolleys. Take special care of sharp edged and pointed<br />

instruments. Never imprint on surgical instruments by impact marking. Striking any hardened instrument can cause stresses and severe<br />

damage may result at a later date.<br />

Avoid as far as possible, contact between stainless steel instruments and any of the following substances: Barium chloride, aluminium chloride.<br />

bromide, iodine.<br />

Lifetime Worldwide Guarantee 7