tesco casing drilling - OilProduction.net

tesco casing drilling - OilProduction.net

tesco casing drilling - OilProduction.net

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Reducing Non-Productive Time<br />

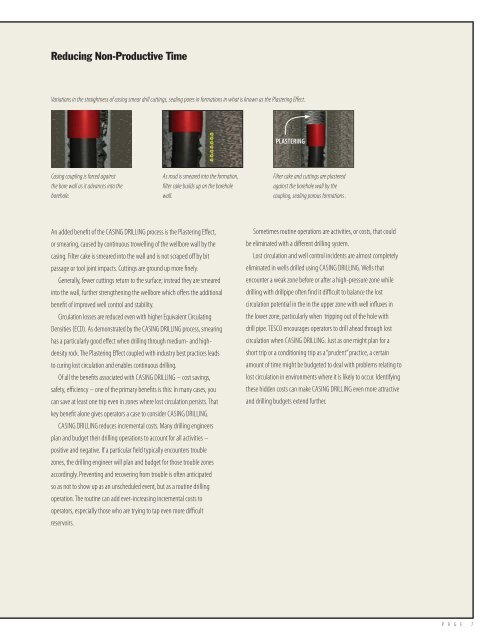

Variations in the straightness of <strong>casing</strong> smear drill cuttings, sealing pores in formations in what is known as the Plastering Eff e c t .<br />

PLASTERING<br />

Casing coupling is forced against<br />

the bore wall as it advances into the<br />

borehole.<br />

As mud is smeared into the formation,<br />

filter cake builds up on the borehole<br />

wall.<br />

Filter cake and cuttings are plastered<br />

against the borehole wall by the<br />

coupling, sealing porous formations .<br />

An added benefit of the CASING DRILLING process is the Plastering Effect,<br />

or smearing, caused by continuous trowelling of the wellbore wall by the<br />

<strong>casing</strong>. Filter cake is smeared into the wall and is not scraped off by bit<br />

passage or tool joint impacts. Cuttings are ground up more finely.<br />

Generally, fewer cuttings return to the surface; instead they are smeared<br />

into the wall, further strengthening the wellbore which offers the additional<br />

benefit of improved well control and stability.<br />

Circulation losses are reduced even with higher Equivalent Circulating<br />

Densities (ECD). As demonstrated by the CASING DRILLING process, smearing<br />

has a particularly good effect when <strong>drilling</strong> through medium- and highdensity<br />

rock. The Plastering Effect coupled with industry best practices leads<br />

to curing lost circulation and enables continuous <strong>drilling</strong>.<br />

Of all the benefits associated with CASING DRILLING – cost savings,<br />

safety, efficiency – one of the primary benefits is this: In many cases, you<br />

can save at least one trip even in zones where lost circulation persists. That<br />

key benefit alone gives operators a case to consider CASING DRILLING.<br />

CASING DRILLING reduces incremental costs. Many <strong>drilling</strong> engineers<br />

plan and budget their <strong>drilling</strong> operations to account for all activities –<br />

positive and negative. If a particular field typically encounters trouble<br />

zones, the <strong>drilling</strong> engineer will plan and budget for those trouble zones<br />

accordingly. Preventing and recovering from trouble is often anticipated<br />

so as not to show up as an unscheduled event, but as a routine <strong>drilling</strong><br />

operation. The routine can add ever-increasing incremental costs to<br />

operators, especially those who are trying to tap even more difficult<br />

reservoirs.<br />

Sometimes routine operations are activities, or costs, that could<br />

be eliminated with a different <strong>drilling</strong> system.<br />

Lost circulation and well control incidents are almost completely<br />

eliminated in wells drilled using CASING DRILLING. Wells that<br />

encounter a weak zone before or after a high-pressure zone while<br />

<strong>drilling</strong> with drillpipe often find it difficult to balance the lost<br />

circulation potential in the in the upper zone with well influxes in<br />

the lower zone, particularly when tripping out of the hole with<br />

drill pipe. TESCO encourages operators to drill ahead through lost<br />

circulation when CASING DRILLING. Just as one might plan for a<br />

short trip or a conditioning trip as a “prudent” practice, a certain<br />

amount of time might be budgeted to deal with problems relating to<br />

lost circulation in environments where it is likely to occur. Identifying<br />

these hidden costs can make CASING DRILLING even more attractive<br />

and <strong>drilling</strong> budgets extend further.<br />

P A G E 7