impact of interruption of antiscalant dosing or cleaning balls ...

impact of interruption of antiscalant dosing or cleaning balls ...

impact of interruption of antiscalant dosing or cleaning balls ...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

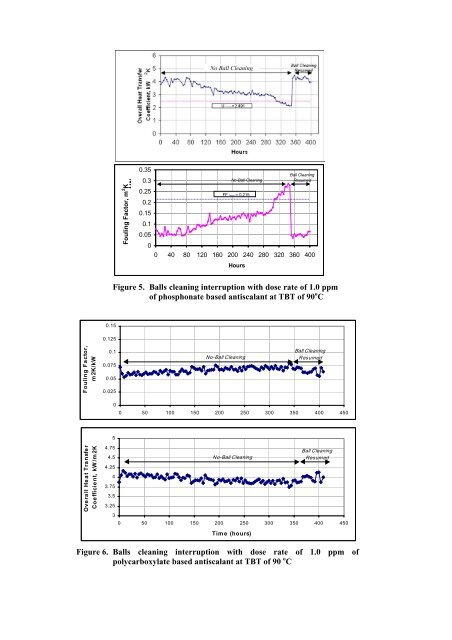

No Ball Cleaning<br />

Fouling Fact<strong>or</strong>, m 2 K /kW<br />

0.35<br />

Ball Cleaning<br />

0.3<br />

No-Ball Cleaning<br />

Resumed<br />

0.25<br />

FF Design = 0.215<br />

0.2<br />

0.15<br />

0.1<br />

0.05<br />

0<br />

0 40 80 120 160 200 240 280 320 360 400<br />

Hours<br />

Figure 5. Balls <strong>cleaning</strong> <strong>interruption</strong> with dose rate <strong>of</strong> 1.0 ppm<br />

<strong>of</strong> phosphonate based <strong>antiscalant</strong> at TBT <strong>of</strong> 90 o C<br />

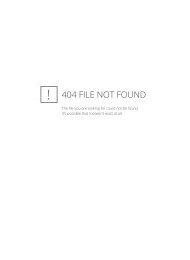

0.15<br />

0.125<br />

Fouling Fact<strong>or</strong>,<br />

m2K/kW<br />

0.1<br />

0.075<br />

0.05<br />

0.025<br />

No-Ball Cleaning<br />

Ball Cleaning<br />

Resumed<br />

0<br />

0 50 100 150 200 250 300 350 400 450<br />

5<br />

Overall Heat Transfer<br />

Coefficient, kW /m2K<br />

4.75<br />

4.5<br />

4.25<br />

4<br />

3.75<br />

3.5<br />

3.25<br />

3<br />

No-Ball Cleaning<br />

0 50 100 150 200 250 300 350 400 450<br />

Time (hours)<br />

Ball Cleaning<br />

Resumed<br />

Figure 6. Balls <strong>cleaning</strong> <strong>interruption</strong> with dose rate <strong>of</strong> 1.0 ppm <strong>of</strong><br />

polycarboxylate based <strong>antiscalant</strong> at TBT <strong>of</strong> 90 o C