S460GDRF High-strength hot-dip galvanised steel - Tata Steel

S460GDRF High-strength hot-dip galvanised steel - Tata Steel

S460GDRF High-strength hot-dip galvanised steel - Tata Steel

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

<strong>S460GDRF</strong> is an extension to <strong>Tata</strong> <strong>Steel</strong>’s<br />

<strong>hot</strong>-<strong>dip</strong> <strong>galvanised</strong> (HDG) structural <strong>steel</strong> family.<br />

It has been developed in response to the<br />

requirements of both leading cold-formed section<br />

rollers and construction sector component and<br />

system manufacturers.<br />

<strong>S460GDRF</strong> offers improved value for applications<br />

with high <strong>strength</strong> and limited formability<br />

requirements.<br />

Typical applications:<br />

This high <strong>strength</strong> metallic-coated product is used for a range of<br />

construction applications, including:<br />

• Purlins and side rails<br />

• Floor decking<br />

• Industrial storage tanks<br />

• Mezzanine flooring<br />

Benefits:<br />

The application of this product allows customers to exploit a range of<br />

associated benefits, including:<br />

• Excellent <strong>strength</strong>/weight ratio<br />

• Good formability suitable for most rolled formed sections<br />

• A cost effective solution<br />

• Easier and safer handling of components on-site<br />

• Associated environmental benefits including improved carbon footprint<br />

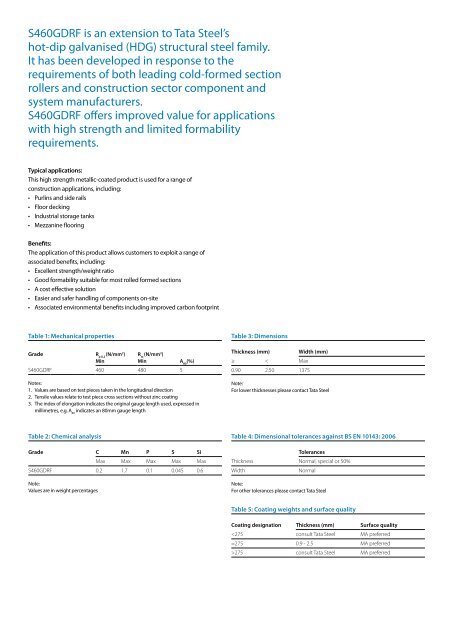

Table 1: Mechanical properties<br />

Grade R p 0.2<br />

(N/mm 2 )<br />

Min<br />

R m<br />

(N/mm 2 )<br />

Min A 80<br />

(%)<br />

<strong>S460GDRF</strong> 460 480 5<br />

Notes:<br />

1. Values are based on test pieces taken in the longitudinal direction<br />

2. Tensile values relate to test piece cross sections without zinc coating<br />

3. The index of elongation indicates the original gauge length used, expressed in<br />

millimetres, e.g. A 80<br />

indicates an 80mm gauge length<br />

Table 3: Dimensions<br />

Thickness (mm)<br />

Width (mm)<br />

≥ < Max<br />

0.90 2.50 1375<br />

Note:<br />

For lower thicknesses please contact <strong>Tata</strong> <strong>Steel</strong><br />

Table 2: Chemical analysis<br />

Grade C Mn P S Si<br />

Max Max Max Max Max<br />

<strong>S460GDRF</strong> 0.2 1.7 0.1 0.045 0.6<br />

Note:<br />

Values are in weight percentages<br />

Table 4: Dimensional tolerances against BS EN 10143: 2006<br />

Tolerances<br />

Thickness Normal, special or 50%<br />

Width<br />

Normal<br />

Note:<br />

For other tolerances please contact <strong>Tata</strong> <strong>Steel</strong><br />

Table 5: Coating weights and surface quality<br />

Coating designation Thickness (mm) Surface quality<br />

275 consult <strong>Tata</strong> <strong>Steel</strong> MA preferred