Buildcrete Datasheet - Lafarge in South Africa

Buildcrete Datasheet - Lafarge in South Africa

Buildcrete Datasheet - Lafarge in South Africa

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

BUILDCRETE<br />

Designed for customers’<br />

convenience<br />

User-friendly <strong>Buildcrete</strong> ma<strong>in</strong>ta<strong>in</strong>s <strong>Lafarge</strong> Cement’s tradition of<br />

technical excellence and product <strong>in</strong>novation:<br />

• Superior workability for easy-to-handle, productive concrete<br />

and mortar work<br />

• Strength that meets the needs of domestic and most<br />

contract site projects<br />

• Quality and reliability of the renowned <strong>Buildcrete</strong> brand<br />

• Early strength ga<strong>in</strong> to complete jobs quicker<br />

• The ‘Greenest’ formulation <strong>in</strong> our unique environmentallyfriendly<br />

range of products<br />

Concern for the environment<br />

<strong>Lafarge</strong> has for many years been one of the leaders <strong>in</strong> the build<strong>in</strong>g<br />

materials <strong>in</strong>dustry for actively pursu<strong>in</strong>g susta<strong>in</strong>able development<br />

policies. The Group’s responsible environmental practices have reduced<br />

its global carbon dioxide (a ‘greenhouse’ gas) emissions by 18% s<strong>in</strong>ce<br />

1990. Contribut<strong>in</strong>g to this achievement, <strong>Lafarge</strong> Cement is the only<br />

<strong>South</strong> <strong>Africa</strong>n cement manufacturer to have a complete range of ‘green’<br />

products.<br />

• Lichtenburg Cement Works produces <strong>Buildcrete</strong> CEM IV/B-V<br />

32,5R, a Pozzolanic cement, formulated from Portland cl<strong>in</strong>ker<br />

and quality siliceous fly ash, together with a strength enhancer<br />

• Richards Bay plant produces <strong>Buildcrete</strong> as a CEM IV/A-V<br />

32,5R Portland-fly ash cement. The formulation is based on<br />

quality siliceous fly ash <strong>in</strong>terground with Portland cement<br />

cl<strong>in</strong>ker together with a strength-enhanc<strong>in</strong>g additive.<br />

Recommended mix designs<br />

A standard builder’s wheelbarrow that holds 65 litres of material<br />

is generally used to measure out the correct volumes of cement,<br />

stone and sand required to make a batch of concrete. <strong>Buildcrete</strong><br />

is supplied <strong>in</strong> 50kg bags for use <strong>in</strong> a wide range of smaller jobs,<br />

as <strong>in</strong>dicated <strong>in</strong> the mix proportions tables below. 2 x 50kg bags<br />

(often still referred to as ‘pockets’) are equivalent <strong>in</strong> volume to one<br />

wheelbarrow load.<br />

Note: If you want to make a smaller batch of concrete, remember<br />

to use the same size conta<strong>in</strong>er (for example a bucket) to measure<br />

all the <strong>in</strong>gredients. (Us<strong>in</strong>g a shovel to measure materials is not<br />

recommended because you cannot judge the quantities accurately.)<br />

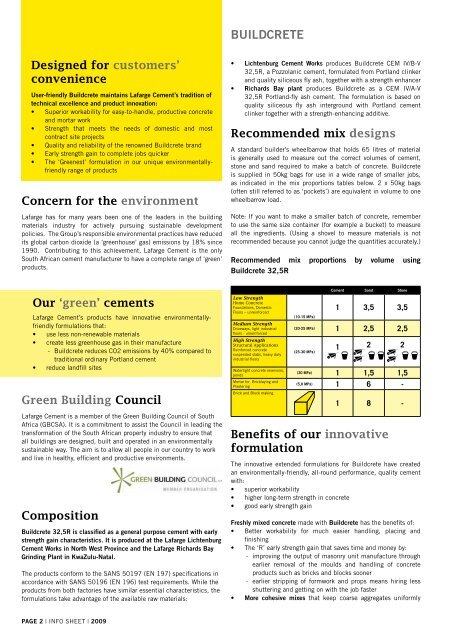

Recommended mix proportions by volume us<strong>in</strong>g<br />

<strong>Buildcrete</strong> 32,5R<br />

Our ‘green’ cements<br />

<strong>Lafarge</strong> Cement’s products have <strong>in</strong>novative environmentallyfriendly<br />

formulations that:<br />

• use less non-renewable materials<br />

• create less greenhouse gas <strong>in</strong> their manufacture<br />

- <strong>Buildcrete</strong> reduces CO2 emissions by 40% compared to<br />

traditional ord<strong>in</strong>ary Portland cement<br />

• reduce landfill sites<br />

Green Build<strong>in</strong>g Council<br />

Low Strength<br />

Home Concrete<br />

Foundations, Domestic<br />

Floors – unre<strong>in</strong>forced<br />

Medium Strength<br />

Driveways, light <strong>in</strong>dustrial<br />

floors - unre<strong>in</strong>forced<br />

High Strength<br />

Structural Applications<br />

Re<strong>in</strong>forced concrete<br />

suspended slabs, heavy duty<br />

<strong>in</strong>dustrial floors<br />

Watertight concrete reservoirs,<br />

ponds<br />

Mortar for Bricklay<strong>in</strong>g and<br />

Plaster<strong>in</strong>g<br />

Brick and Block mak<strong>in</strong>g<br />

(10-15 MPa)<br />

Cement Sand Stone<br />

1 3,5 3,5<br />

(20-25 MPa) 1 2,5 2,5<br />

(25-30 MPa)<br />

1 2 2<br />

(30 MPa) 1 1,5 1,5<br />

(5,0 MPa) 1 6 -<br />

1 8 -<br />

<strong>Lafarge</strong> Cement is a member of the Green Build<strong>in</strong>g Council of <strong>South</strong><br />

<strong>Africa</strong> (GBCSA). It is a commitment to assist the Council <strong>in</strong> lead<strong>in</strong>g the<br />

transformation of the <strong>South</strong> <strong>Africa</strong>n property <strong>in</strong>dustry to ensure that<br />

all build<strong>in</strong>gs are designed, built and operated <strong>in</strong> an environmentally<br />

susta<strong>in</strong>able way. The aim is to allow all people <strong>in</strong> our country to work<br />

and live <strong>in</strong> healthy, efficient and productive environments.<br />

Composition<br />

<strong>Buildcrete</strong> 32,5R is classified as a general purpose cement with early<br />

strength ga<strong>in</strong> characteristics. It is produced at the <strong>Lafarge</strong> Lichtenburg<br />

Cement Works <strong>in</strong> North West Prov<strong>in</strong>ce and the <strong>Lafarge</strong> Richards Bay<br />

Gr<strong>in</strong>d<strong>in</strong>g Plant <strong>in</strong> KwaZulu-Natal.<br />

The products conform to the SANS 50197 (EN 197) specifications <strong>in</strong><br />

accordance with SANS 50196 (EN 196) test requirements. While the<br />

products from both factories have similar essential characteristics, the<br />

formulations take advantage of the available raw materials:<br />

Benefits of our <strong>in</strong>novative<br />

formulation<br />

The <strong>in</strong>novative extended formulations for <strong>Buildcrete</strong> have created<br />

an environmentally-friendly, all-round performance, quality cement<br />

with:<br />

• superior workability<br />

• higher long-term strength <strong>in</strong> concrete<br />

• good early strength ga<strong>in</strong><br />

Freshly mixed concrete made with <strong>Buildcrete</strong> has the benefits of:<br />

• Better workability for much easier handl<strong>in</strong>g, plac<strong>in</strong>g and<br />

f<strong>in</strong>ish<strong>in</strong>g<br />

• The ‘R’ early strength ga<strong>in</strong> that saves time and money by:<br />

- improv<strong>in</strong>g the output of masonry unit manufacture through<br />

earlier removal of the moulds and handl<strong>in</strong>g of concrete<br />

products such as bricks and blocks sooner<br />

- earlier stripp<strong>in</strong>g of formwork and props means hir<strong>in</strong>g less<br />

shutter<strong>in</strong>g and gett<strong>in</strong>g on with the job faster<br />

• More cohesive mixes that keep coarse aggregates uniformly<br />

PAGE 2 | INFO SHEET | 2009