Zinc Sheet Environmental Profile - Life Cycle Assessment

Zinc Sheet Environmental Profile - Life Cycle Assessment

Zinc Sheet Environmental Profile - Life Cycle Assessment

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

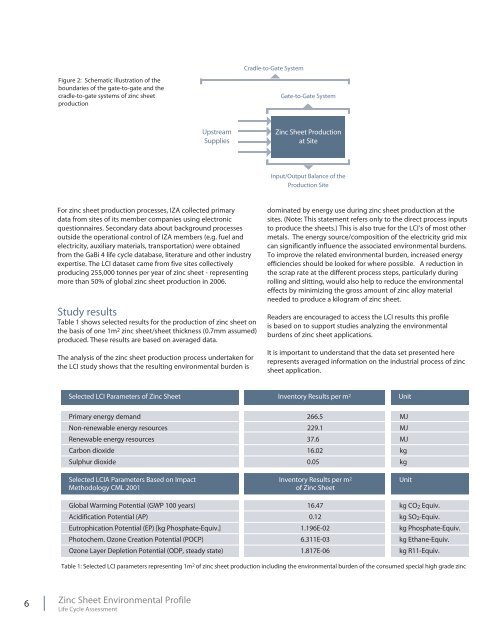

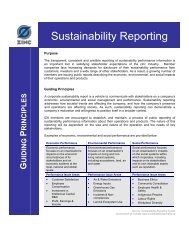

Cradle-to-Gate System<br />

Figure 2: Schematic illustration of the<br />

boundaries of the gate‐to‐gate and the<br />

cradle‐to‐gate systems of zinc sheet<br />

production<br />

Gate-to-Gate System<br />

Upstream<br />

Supplies<br />

<strong>Zinc</strong> <strong>Sheet</strong> Production<br />

at Site<br />

Input/Output Balance of the<br />

Production Site<br />

For zinc sheet production processes, IZA collected primary<br />

data from sites of its member companies using electronic<br />

questionnaires. Secondary data about background processes<br />

outside the operational control of IZA members (e.g. fuel and<br />

electricity, auxiliary materials, transportation) were obtained<br />

from the GaBi 4 life cycle database, literature and other industry<br />

expertise. The LCI dataset came from five sites collectively<br />

producing 255,000 tonnes per year of zinc sheet - representing<br />

more than 50% of global zinc sheet production in 2006.<br />

Study results<br />

Table 1 shows selected results for the production of zinc sheet on<br />

the basis of one 1m 2 zinc sheet/sheet thickness (0.7mm assumed)<br />

produced. These results are based on averaged data.<br />

The analysis of the zinc sheet production process undertaken for<br />

the LCI study shows that the resulting environmental burden is<br />

dominated by energy use during zinc sheet production at the<br />

sites. (Note: This statement refers only to the direct process inputs<br />

to produce the sheets.) This is also true for the LCI’s of most other<br />

metals. The energy source/composition of the electricity grid mix<br />

can significantly influence the associated environmental burdens.<br />

To improve the related environmental burden, increased energy<br />

efficiencies should be looked for where possible. A reduction in<br />

the scrap rate at the different process steps, particularly during<br />

rolling and slitting, would also help to reduce the environmental<br />

effects by minimizing the gross amount of zinc alloy material<br />

needed to produce a kilogram of zinc sheet.<br />

Readers are encouraged to access the LCI results this profile<br />

is based on to support studies analyzing the environmental<br />

burdens of zinc sheet applications.<br />

It is important to understand that the data set presented here<br />

represents averaged information on the industrial process of zinc<br />

sheet application.<br />

Selected LCI Parameters of <strong>Zinc</strong> <strong>Sheet</strong> Inventory Results per m 2 Unit<br />

Primary energy demand 266.5 MJ<br />

Non-renewable energy resources 229.1 MJ<br />

Renewable energy resources 37.6 MJ<br />

Carbon dioxide 16.02 kg<br />

Sulphur dioxide 0.05 kg<br />

Selected LCIA Parameters Based on Impact Inventory Results per m 2 Unit<br />

Methodology CML 2001<br />

of <strong>Zinc</strong> <strong>Sheet</strong><br />

Global Warming Potential (GWP 100 years) 16.47 kg CO 2 Equiv.<br />

Acidification Potential (AP) 0.12 kg SO 2 -Equiv.<br />

Eutrophication Potential (EP) [kg Phosphate-Equiv.] 1.196E-02 kg Phosphate-Equiv.<br />

Photochem. Ozone Creation Potential (POCP) 6.311E-03 kg Ethane-Equiv.<br />

Ozone Layer Depletion Potential (ODP, steady state) 1.817E-06 kg R11-Equiv.<br />

Table 1: Selected LCI parameters representing 1m 2 of zinc sheet production including the environmental burden of the consumed special high grade zinc<br />

6 <strong>Zinc</strong> <strong>Sheet</strong> <strong>Environmental</strong> <strong>Profile</strong><br />

<strong>Life</strong> <strong>Cycle</strong> <strong>Assessment</strong>