aluminium for future generations sustainability update 2005

aluminium for future generations sustainability update 2005

aluminium for future generations sustainability update 2005

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

ALUMINIUM FOR FUTURE<br />

GENERATIONS<br />

The Aluminium <strong>for</strong> Future Generations initiative is<br />

a programme of continuous improvement on the<br />

part of the global <strong>aluminium</strong> industry, overseen by<br />

the International Aluminium Institute (IAI). It<br />

comprises voluntary objectives, currently thirteen in<br />

number but increasing year by year, related to all<br />

key phases of <strong>aluminium</strong>’s life cycle. The<br />

industry’s per<strong>for</strong>mance towards meeting these<br />

objectives is measured annually against twenty two<br />

per<strong>for</strong>mance indicators. This <strong>update</strong> reports on<br />

year <strong>2005</strong> per<strong>for</strong>mance recorded in the annual<br />

survey of <strong>sustainability</strong> data collected from IAI<br />

member companies, collectively responsible <strong>for</strong><br />

over 70% of global primary <strong>aluminium</strong> production<br />

and around 20% of recycled metal production. For<br />

further in<strong>for</strong>mation on IAI members, please visit the<br />

World Aluminium website.<br />

This year survey data was collected from:<br />

• 75 smelters representing almost 18 million<br />

tonnes of primary <strong>aluminium</strong> production, a<br />

21% increase on 2004 coverage and<br />

equivalent to 55% of total global <strong>aluminium</strong><br />

production;<br />

• 24 refineries representing over 36 million<br />

tonnes of smelter grade alumina, a 41%<br />

increase on 2004 coverage and equivalent to<br />

around 60% of total global alumina production;<br />

• 11 mines representing over 81 million tonnes<br />

of bauxite, a 13% increase on 2004 coverage<br />

and equivalent to around 50% of total global<br />

bauxite production.<br />

<strong>2005</strong> Sustainability Per<strong>for</strong>mance<br />

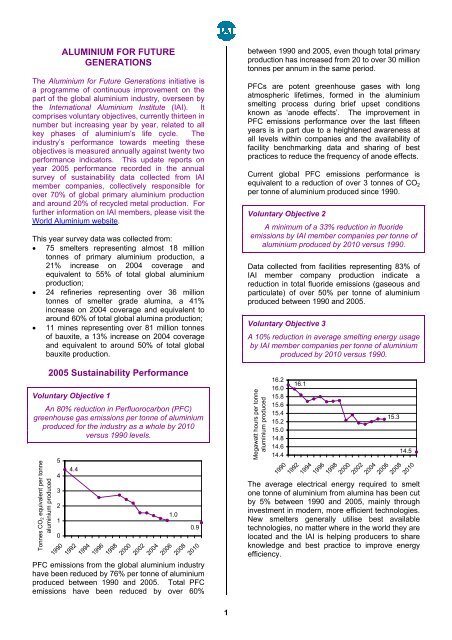

Voluntary Objective 1<br />

An 80% reduction in Perfluorocarbon (PFC)<br />

greenhouse gas emissions per tonne of <strong>aluminium</strong><br />

produced <strong>for</strong> the industry as a whole by 2010<br />

versus 1990 levels.<br />

Tonnes CO 2 equivalent per tonne<br />

<strong>aluminium</strong> produced<br />

5<br />

4<br />

3<br />

2<br />

1<br />

0<br />

4.4<br />

1990<br />

1992<br />

1.0<br />

1994<br />

1996<br />

1998<br />

2000<br />

2002<br />

2004<br />

2006<br />

0.9<br />

2008<br />

2010<br />

PFC emissions from the global <strong>aluminium</strong> industry<br />

have been reduced by 76% per tonne of <strong>aluminium</strong><br />

produced between 1990 and <strong>2005</strong>. Total PFC<br />

emissions have been reduced by over 60%<br />

between 1990 and <strong>2005</strong>, even though total primary<br />

production has increased from 20 to over 30 million<br />

tonnes per annum in the same period.<br />

PFCs are potent greenhouse gases with long<br />

atmospheric lifetimes, <strong>for</strong>med in the <strong>aluminium</strong><br />

smelting process during brief upset conditions<br />

known as ‘anode effects’. The improvement in<br />

PFC emissions per<strong>for</strong>mance over the last fifteen<br />

years is in part due to a heightened awareness at<br />

all levels within companies and the availability of<br />

facility benchmarking data and sharing of best<br />

practices to reduce the frequency of anode effects.<br />

Current global PFC emissions per<strong>for</strong>mance is<br />

equivalent to a reduction of over 3 tonnes of CO 2<br />

per tonne of <strong>aluminium</strong> produced since 1990.<br />

Voluntary Objective 2<br />

A minimum of a 33% reduction in fluoride<br />

emissions by IAI member companies per tonne of<br />

<strong>aluminium</strong> produced by 2010 versus 1990.<br />

Data collected from facilities representing 83% of<br />

IAI member company production indicate a<br />

reduction in total fluoride emissions (gaseous and<br />

particulate) of over 50% per tonne of <strong>aluminium</strong><br />

produced between 1990 and <strong>2005</strong>.<br />

Voluntary Objective 3<br />

A 10% reduction in average smelting energy usage<br />

by IAI member companies per tonne of <strong>aluminium</strong><br />

produced by 2010 versus 1990.<br />

Megawatt hours per tonne<br />

<strong>aluminium</strong> produced<br />

16.2<br />

16.0<br />

15.8<br />

15.6<br />

15.4<br />

15.2<br />

15.0<br />

14.8<br />

14.6<br />

14.4<br />

16.1<br />

1990<br />

1992<br />

15.3<br />

1994<br />

1996<br />

1998<br />

2000<br />

2002<br />

2004<br />

2006<br />

2008<br />

14.5<br />

2010<br />

The average electrical energy required to smelt<br />

one tonne of <strong>aluminium</strong> from alumina has been cut<br />

by 5% between 1990 and <strong>2005</strong>, mainly through<br />

investment in modern, more efficient technologies.<br />

New smelters generally utilise best available<br />

technologies, no matter where in the world they are<br />

located and the IAI is helping producers to share<br />

knowledge and best practice to improve energy<br />

efficiency.<br />

1