LWT - Arkey Group

LWT - Arkey Group

LWT - Arkey Group

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

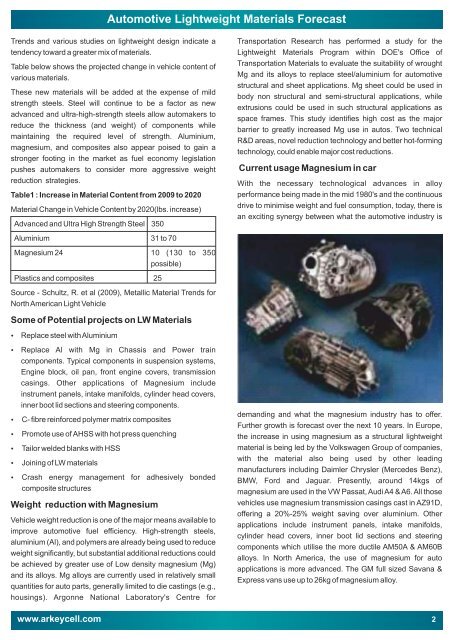

Automotive Lightweight Materials Forecast<br />

Trends and various studies on lightweight design indicate a<br />

tendency toward a greater mix of materials.<br />

Table below shows the projected change in vehicle content of<br />

various materials.<br />

These new materials will be added at the expense of mild<br />

strength steels. Steel will continue to be a factor as new<br />

advanced and ultra-high-strength steels allow automakers to<br />

reduce the thickness (and weight) of components while<br />

maintaining the required level of strength. Aluminium,<br />

magnesium, and composites also appear poised to gain a<br />

stronger footing in the market as fuel economy legislation<br />

pushes automakers to consider more aggressive weight<br />

reduction strategies.<br />

Table1 : Increase in Material Content from 2009 to 2020<br />

Material Change in Vehicle Content by 2020(lbs. increase)<br />

Advanced and Ultra High Strength Steel 350<br />

Aluminium 31 to 70<br />

Magnesium 24<br />

10 (130 to 350<br />

possible)<br />

Plastics and composites 25<br />

Source - Schultz, R. et al (2009), Metallic Material Trends for<br />

North American Light Vehicle<br />

Transportation Research has performed a study for the<br />

Lightweight Materials Program within DOE's Office of<br />

Transportation Materials to evaluate the suitability of wrought<br />

Mg and its alloys to replace steel/aluminium for automotive<br />

structural and sheet applications. Mg sheet could be used in<br />

body non structural and semi-structural applications, while<br />

extrusions could be used in such structural applications as<br />

space frames. This study identifies high cost as the major<br />

barrier to greatly increased Mg use in autos. Two technical<br />

R&D areas, novel reduction technology and better hot-forming<br />

technology, could enable major cost reductions.<br />

Current usage Magnesium in car<br />

With the necessary technological advances in alloy<br />

performance being made in the mid 1980's and the continuous<br />

drive to minimise weight and fuel consumption, today, there is<br />

an exciting synergy between what the automotive industry is<br />

Some of Potential projects on LW Materials<br />

Ÿ Replace steel with Aluminium<br />

Ÿ Replace Al with Mg in Chassis and Power train<br />

components. Typical components in suspension systems,<br />

Engine block, oil pan, front engine covers, transmission<br />

casings. Other applications of Magnesium include<br />

instrument panels, intake manifolds, cylinder head covers,<br />

inner boot lid sections and steering components.<br />

Ÿ C- fibre reinforced polymer matrix composites<br />

demanding and what the magnesium industry has to offer.<br />

Further growth is forecast over the next 10 years. In Europe,<br />

Ÿ Promote use of AHSS with hot press quenching the increase in using magnesium as a structural lightweight<br />

Ÿ<br />

Ÿ<br />

Ÿ<br />

Tailor welded blanks with HSS<br />

Joining of LW materials<br />

Crash energy management for adhesively bonded<br />

composite structures<br />

Weight reduction with Magnesium<br />

Vehicle weight reduction is one of the major means available to<br />

improve automotive fuel efficiency. High-strength steels,<br />

aluminium (Al), and polymers are already being used to reduce<br />

weight significantly, but substantial additional reductions could<br />

be achieved by greater use of Low density magnesium (Mg)<br />

and its alloys. Mg alloys are currently used in relatively small<br />

quantities for auto parts, generally limited to die castings (e.g.,<br />

housings). Argonne National Laboratory's Centre for<br />

material is being led by the Volkswagen <strong>Group</strong> of companies,<br />

with the material also being used by other leading<br />

manufacturers including Daimler Chrysler (Mercedes Benz),<br />

BMW, Ford and Jaguar. Presently, around 14kgs of<br />

magnesium are used in the VW Passat, Audi A4 & A6. All those<br />

vehicles use magnesium transmission casings cast in AZ91D,<br />

offering a 20%-25% weight saving over aluminium. Other<br />

applications include instrument panels, intake manifolds,<br />

cylinder head covers, inner boot lid sections and steering<br />

components which utilise the more ductile AM50A & AM60B<br />

alloys. In North America, the use of magnesium for auto<br />

applications is more advanced. The GM full sized Savana &<br />

Express vans use up to 26kg of magnesium alloy.<br />

www.arkeycell.com 2