Thermocouple - NANMAC Corporation

Thermocouple - NANMAC Corporation

Thermocouple - NANMAC Corporation

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

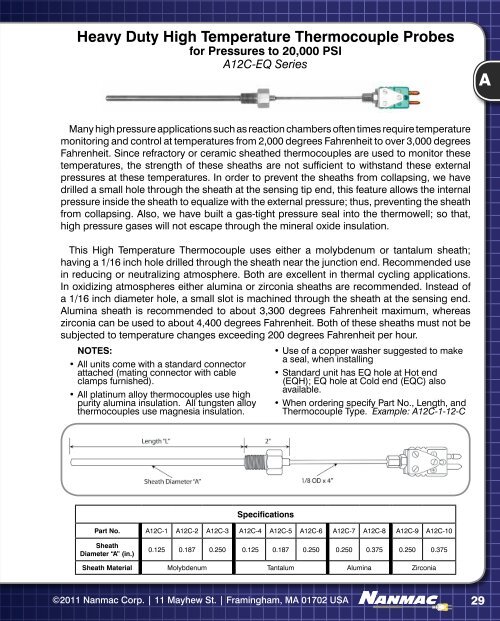

Heavy Duty High Temperature <strong>Thermocouple</strong> Probes<br />

for Pressures to 20,000 PSI<br />

A12C-EQ Series<br />

A<br />

Many high pressure applications such as reaction chambers often times require temperature<br />

monitoring and control at temperatures from 2,000 degrees Fahrenheit to over 3,000 degrees<br />

Fahrenheit. Since refractory or ceramic sheathed thermocouples are used to monitor these<br />

temperatures, the strength of these sheaths are not sufficient to withstand these external<br />

pressures at these temperatures. In order to prevent the sheaths from collapsing, we have<br />

drilled a small hole through the sheath at the sensing tip end, this feature allows the internal<br />

pressure inside the sheath to equalize with the external pressure; thus, preventing the sheath<br />

from collapsing. Also, we have built a gas-tight pressure seal into the thermowell; so that,<br />

high pressure gases will not escape through the mineral oxide insulation.<br />

This High Temperature <strong>Thermocouple</strong> uses either a molybdenum or tantalum sheath;<br />

having a 1/16 inch hole drilled through the sheath near the junction end. Recommended use<br />

in reducing or neutralizing atmosphere. Both are excellent in thermal cycling applications.<br />

In oxidizing atmospheres either alumina or zirconia sheaths are recommended. Instead of<br />

a 1/16 inch diameter hole, a small slot is machined through the sheath at the sensing end.<br />

Alumina sheath is recommended to about 3,300 degrees Fahrenheit maximum, whereas<br />

zirconia can be used to about 4,400 degrees Fahrenheit. Both of these sheaths must not be<br />

subjected to temperature changes exceeding 200 degrees Fahrenheit per hour.<br />

NOTES:<br />

• All units come with a standard connector<br />

attached (mating connector with cable<br />

clamps furnished).<br />

• All platinum alloy thermocouples use high<br />

purity alumina insulation. All tungsten alloy<br />

thermocouples use magnesia insulation.<br />

• Use of a copper washer suggested to make<br />

a seal, when installing<br />

• Standard unit has EQ hole at Hot end<br />

(EQH); EQ hole at Cold end (EQC) also<br />

available.<br />

• When ordering specify Part No., Length, and<br />

<strong>Thermocouple</strong> Type. Example: A12C-1-12-C<br />

Specifications<br />

Part No. A12C-1 A12C-2 A12C-3 A12C-4 A12C-5 A12C-6 A12C-7 A12C-8 A12C-9 A12C-10<br />

Sheath<br />

Diameter “A” (in.)<br />

0.125 0.187 0.250 0.125 0.187 0.250 0.250 0.375 0.250 0.375<br />

Sheath Material Molybdenum Tantalum Alumina Zirconia<br />

©2011 Nanmac Corp. | 11 Mayhew St. | Framingham, MA 01702 USA 29