JSAE 2009 - Moving Magnet Technologies

JSAE 2009 - Moving Magnet Technologies

JSAE 2009 - Moving Magnet Technologies

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

3 The Torque Motor<br />

A special task is the positioning of valves<br />

and flaps, particularly in the area of air<br />

supply and exhaust removal. These<br />

components must often work under very<br />

harsh conditions and have to meet high<br />

standards of performance, reliability,<br />

force density and precision. Sonceboz<br />

developed the torque motor for such<br />

tasks and has been producing more than<br />

15 million units since the year 2000.<br />

Several million are produced every year.<br />

3.1 Advantages of the Torque<br />

Motor<br />

The high torque vs. mass ratio optimizes<br />

weight and size. The peak to nominal<br />

torque ratio high and the torque output<br />

can be maximized for short time periods.<br />

•Since the torque runs proportional to<br />

the current, the regulation can take place<br />

by means of simple and conventional<br />

methods.<br />

•Very low detent torque makes it<br />

possible to use a minimized return<br />

spring and thereby to reduce the holding<br />

current.<br />

•The design as a direct drive provides for<br />

high reliability and service life.<br />

•The use of permanent magnets in the<br />

rotor and the possible integration of a<br />

contactless sensor enable a totally<br />

brushless solution.<br />

•The possible integration of drive and<br />

controller electronics enables a compact,<br />

intelligent drive system.<br />

.<br />

3.2 The Operating Principle<br />

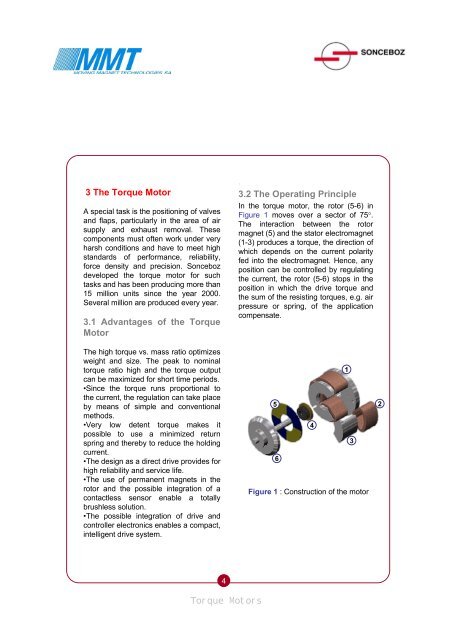

In the torque motor, the rotor (5-6) in<br />

Figure 1 moves over a sector of 75°.<br />

The interaction between the rotor<br />

magnet (5) and the stator electromagnet<br />

(1-3) produces a torque, the direction of<br />

which depends on the current polarity<br />

fed into the electromagnet. Hence, any<br />

position can be controlled by regulating<br />

the current, the rotor (5-6) stops in the<br />

position in which the drive torque and<br />

the sum of the resisting torques, e.g. air<br />

pressure or spring, of the application<br />

compensate.<br />

5<br />

6<br />

Figure 1 : Construction of the motor<br />

4<br />

1<br />

3<br />

2<br />

4<br />

Torque Motors