HVAC Spec Sheet

HVAC Spec Sheet

HVAC Spec Sheet

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

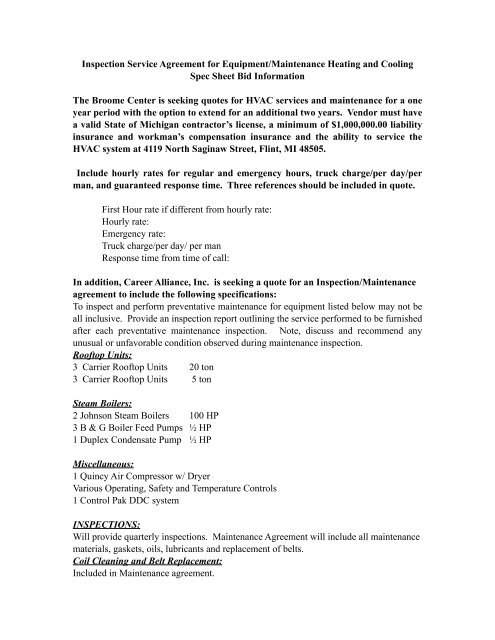

Inspection Service Agreement for Equipment/Maintenance Heating and Cooling<br />

<strong>Spec</strong> <strong>Sheet</strong> Bid Information<br />

The Broome Center is seeking quotes for <strong>HVAC</strong> services and maintenance for a one<br />

year period with the option to extend for an additional two years. Vendor must have<br />

a valid State of Michigan contractor’s license, a minimum of $1,000,000.00 liability<br />

insurance and workman’s compensation insurance and the ability to service the<br />

<strong>HVAC</strong> system at 4119 North Saginaw Street, Flint, MI 48505.<br />

Include hourly rates for regular and emergency hours, truck charge/per day/per<br />

man, and guaranteed response time. Three references should be included in quote.<br />

First Hour rate if different from hourly rate:<br />

Hourly rate:<br />

Emergency rate:<br />

Truck charge/per day/ per man<br />

Response time from time of call:<br />

In addition, Career Alliance, Inc. is seeking a quote for an Inspection/Maintenance<br />

agreement to include the following specifications:<br />

To inspect and perform preventative maintenance for equipment listed below may not be<br />

all inclusive. Provide an inspection report outlining the service performed to be furnished<br />

after each preventative maintenance inspection. Note, discuss and recommend any<br />

unusual or unfavorable condition observed during maintenance inspection.<br />

Rooftop Units:<br />

3 Carrier Rooftop Units 20 ton<br />

3 Carrier Rooftop Units 5 ton<br />

Steam Boilers:<br />

2 Johnson Steam Boilers 100 HP<br />

3 B & G Boiler Feed Pumps ½ HP<br />

1 Duplex Condensate Pump ½ HP<br />

Miscellaneous:<br />

1 Quincy Air Compressor w/ Dryer<br />

Various Operating, Safety and Temperature Controls<br />

1 Control Pak DDC system<br />

INSPECTIONS:<br />

Will provide quarterly inspections. Maintenance Agreement will include all maintenance<br />

materials, gaskets, oils, lubricants and replacement of belts.<br />

Coil Cleaning and Belt Replacement:<br />

Included in Maintenance agreement.

Service Documentation:<br />

All scheduled and unscheduled service work will be documented and copy left with<br />

agency. This is to include date and time of service, technician, equipment identification<br />

and detailed description of work performed.<br />

Refrigerant Containment Service:<br />

Leak Test and report any equipment found low of refrigerant. Will use recovery,<br />

recycling and reclamation of refrigerant as appropriate to minimize cost of replacement<br />

refrigerant.<br />

Air Filter Maintenance:<br />

Included in Maintenance agreement will be 4 air filter changes per year. This will<br />

include material (filters), labor and proper disposal of used filters.<br />

Spring (April) Start A/C:<br />

Late Spring/<br />

Early Summer:<br />

Summer (July):<br />

Fall (September):<br />

Grease all bearings<br />

Start, test and check six condensing units along with wire<br />

terminators<br />

Check all belts on supply and return fans<br />

Check operation of all OA and RA dampers, set minimum<br />

OA to no less than 20%<br />

Check condition of filters<br />

Check pneumatic compressor belt and condensate drain of<br />

tank<br />

Check pneumatic air dryer<br />

Check space thermostats etc.<br />

Off Season Lay-Up of Boilers<br />

Condenser coil cleaning (when the cottonwoods are no<br />

longer shedding)<br />

Check six condensing units<br />

Check refrigeration charge and expansion and solenoid<br />

valves<br />

Start two boilers<br />

Perform Rule 27 for State of Michigan – CSD -1<br />

Check all relief valves<br />

Check all low water cutoffs, pressure controls, gas, steam<br />

and water<br />

Check all burners, pilots, safeties, etc.<br />

Fire boilers, CTS, combustion spot checks

Check all expansion tanks, PRV’s feed water temperature<br />

control<br />

Check all dampers, motors, lineage controls, etc.<br />

Space thermostat and operators<br />

Check for H/W flow through all offices<br />

Air Handlers:<br />

Winter (December):<br />

Annually:<br />

Check all belts on supply and fan return fans<br />

Grease all bearings<br />

Check all belts on pneumatic compressors<br />

Check all mechanical room unit ventilators<br />

Check air dryers and condensate tank drains<br />

Check all dampers, motor, lineage controls, etc.<br />

Checks space thermostats and operation<br />

Check two boilers and operations<br />

Check feed pumps, condensate tanks and pumps<br />

Check all low water cutoffs, relief valves, safeties, etc.<br />

Check expansion tanks and PRV‘s<br />

Check boiler firing, stack temperatures, steam pressure and<br />

hot water temperatures<br />

Check combustion air supply<br />

General look at space control<br />

Check all damper operations plus minimum position<br />

settings<br />

Equipment belt replacement<br />

Material-All belts and filters are included in the price of<br />

this agreement.<br />

Appointments to view <strong>HVAC</strong> system can be made July 23, 2012 – July 27, 2012 by<br />

contacting Craig Coney, at (810) 233-5974, ext. 110. Appointments are required.<br />

Responses to this quote must be mailed to:<br />

Career Alliance, Inc.<br />

Attention: Workforce Training Department<br />

<strong>HVAC</strong> RFQ<br />

P.O. Box 528<br />

Flint, MI 48501<br />

Quotes must be received in the P.O. Box by Monday, August 6, 2012.