fire pump controller - Metron Eledyne

fire pump controller - Metron Eledyne

fire pump controller - Metron Eledyne

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

SPECIALISTS IN FIRE PUMP CONTROL SY<br />

<strong>Eledyne</strong><br />

FIRE PUMP CONTROLLER<br />

for Diesel Engine Fire <strong>pump</strong>s<br />

EFP/LPC2000<br />

Logic based release 3.0 spec 3/9806<br />

Complies to BS5306, LPS and EN12845

FEATURES<br />

The <strong>Metron</strong> <strong>Eledyne</strong> Autostart type EFP/LPC/2000 Diesel Engine Fire Pump Controller is<br />

designed in accordance with the requirements of BS5306 part II and LPC regulations (Formerly<br />

FOC Rules- 29th Edition) for automatic and manual starting of diesel-driven <strong>fire</strong>water <strong>pump</strong>s<br />

for automatic sprinkler installations. There is also an option to upgrade this <strong>controller</strong> so that it<br />

meets the diesel engine standard LPS1239. (Option LPS). A simple software adjustment also<br />

means that this <strong>controller</strong> can fully comply to EN12845.<br />

Components are mainly mounted on a printed circuit board and modular for ease of<br />

maintenance. These are contained in a wall mounting, sheet steel, dust and drip-proof<br />

enclosure (IP51) with lock-up front access door. External wiring terminates at a clearly<br />

marked terminal rail.<br />

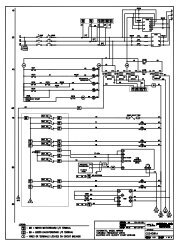

CONTROL SYSTEM<br />

‘Autostart’ operation powered by engine<br />

batteries only - independent of other<br />

sources of power and is initiated by<br />

sprinkler system low pressure as standard.<br />

Other initiating signals can also be<br />

accommodated.<br />

The <strong>controller</strong> is designed to provide up to six<br />

repeat 15 second cranks in a start cycle from<br />

the selected automatic battery, each crank<br />

separated by a dwell period of 10 seconds. In<br />

the event of the selected automatic battery<br />

set failing, the <strong>controller</strong> automatically selects<br />

the alternative battery set for the remaining<br />

cranks. If the engine fails to start after the<br />

sixth attempt, the <strong>controller</strong> will lock-out and<br />

initiate a failed to start alarm. Cranking is<br />

discontinued immediately following the<br />

detection of an engine run signal. An integral<br />

repeat start unit is provided, which<br />

disengages the crank solenoid momentarily if<br />

the starter fails to correctly engage under<br />

automatic start conditions.<br />

Manual Test Start facility (pushbutton<br />

initiated) is enabled after an automatic<br />

start, and indicates a visual warning<br />

indicator that manual test start is required.<br />

The manual test start and emergency<br />

manual start facilities are independent of<br />

the autostart test control system.<br />

No. Description Colour I.D.<br />

1 Battery 1 Ammeter A1<br />

3 Battery 2 Ammeter TAC<br />

5 Annunciator Module<br />

8 Test Start Push Button Green PB1<br />

9 Engine Hours Run Meter HR<br />

10 Emergency Start Push Button Green PB5<br />

11 AC/DC Isolator SW3<br />

12 DC Isolated Lamp Red L1<br />

Two independent fully-automatic battery<br />

chargers are incorporated, each with<br />

maximum output current limited to 5 or 10<br />

Amps with constant potential output at<br />

trickle charge to prevent battery gassing.<br />

Boost charge facility and charge rate<br />

ammeter are provided for each battery<br />

charger. Battery voltmeter and selector<br />

switch are available as an optional extra.<br />

Additional engine instrumentation gauges<br />

and monitoring systems are available as<br />

optional extras.

SPECIFICATIONS<br />

The door is lockable by use of the top door<br />

lock and AC isolator. The AC isolator is door<br />

interlocked and maybe be locked in the off<br />

position for maintenance purposes.<br />

The <strong>controller</strong> can be adjusted by software<br />

to comply with EN12845. The nature of the<br />

change relates to the crank sequence. In<br />

this mode, the auto crank cycle alternates<br />

the cranking battery from A to B after each<br />

crank attempt. The duty selector switch is<br />

not required for EN12845 versions.<br />

NEW LPS1239<br />

COMPLIANT<br />

The EFP/LPC2000 <strong>controller</strong> can now<br />

be upgraded so that it can be<br />

connected to a diesel engine which is<br />

approved to LPS1239.<br />

The upgrade includes: (See option<br />

‘LPS’ on the option list)<br />

• Isolated output for engine<br />

mounted tachometer<br />

• Protected engine jacket heater<br />

output, 1.5kW<br />

• Low Jacket temperature alarm &<br />

monitor<br />

• Engine stop solenoid output and<br />

push button<br />

Controller Status Signals<br />

Battery A healthy<br />

Battery B healthy<br />

Battery A boost charge on<br />

Battery B boost charge on<br />

Controller Alarm Signals<br />

Pump on demand<br />

Engine running<br />

Engine failed to start<br />

When lit, press test start<br />

Remote alarm signals (Volt free contacts)<br />

Pump on demand<br />

Engine running<br />

Engine failed to start<br />

D.C. battery supply failure<br />

Controls and instrumentation<br />

Combined A.C./D.C. supplies isolator<br />

(door-interlocked)<br />

Emergency manual start pushbutton<br />

(behind break glass flap)<br />

Manual start test pushbutton<br />

Alarm reset pushbutton<br />

Battery charger A ammeter<br />

Battery charger B ammeter<br />

Battery A/B automatic duty selector switch<br />

Engine hours run counter<br />

DC Isolated lamp<br />

Audible alarm<br />

ORDER CODE<br />

EFP 12V 120V LPC2000 OPTIONS<br />

24V<br />

230V<br />

When ordering, please specify; Engine manufacturer and model number.<br />

Engine start batteries, Lead-acid/Nickel cadmium, 12/24v, Ah capacity.<br />

A.C. mains supply, voltage & frequency.<br />

For speed switch option, number of teeth on engine flywheel & crank cut-off speed.<br />

Any optional extras required. EC ‘CE’ marking/certificate of conformity.<br />

003<br />

FM55714

SPECIALISTS IN FIRE PUMP CONTROL SY<br />

<strong>Metron</strong> <strong>Eledyne</strong> Ltd<br />

18 Autumn Park, Dysart Road, Grantham<br />

Lincolnshire NG31 7DD. United Kingdom<br />

Tel: +44 1476 516120<br />

Fax: +44 1476 516121<br />

Email: info@metroneledyne.co.uk<br />

Website: www.metroneledyne.co.uk<br />

<strong>Metron</strong> Inc<br />

1505 West Third Avenue<br />

Denver, CO 80223, United States of America<br />

Tel: +1 303 592 1903<br />

Fax: +1 303 534 1947<br />

<strong>Eledyne</strong><br />

DESCRIPTION OF OPTIONS<br />

8A<br />

10A<br />

A<br />

B1<br />

B2<br />

C<br />

D<br />

DG<br />

EN<br />

G1<br />

G2<br />

G3<br />

G4<br />

G<br />

8 Amp battery chargers.<br />

Standard battery charger, with manual boost facility<br />

10Amp battery charger.<br />

‘FM’ style automatic boost equalize float type. (Will require a larger than standard<br />

enclosure)<br />

Mains failure start<br />

Adjustable electronic timer which activates the automatic start sequence after the<br />

time delay is completed.<br />

Electronic speed switch (standard)<br />

Takes an electronic pulse from the engine and determines when the engine is<br />

running.<br />

Electronic speed switch (Fiat type)<br />

Same as B1, but for Fiat type engines.<br />

Auto stop timer<br />

Electronic adjustable timer to automatically stop the engine once <strong>pump</strong> on demand<br />

has cleared.<br />

Delay start timer (Sequence start)<br />

This is used to prevent the engine from starting upon a sudden pressure drop, thus<br />

ensuring that the engine is only started in a true low pressure situation. This option<br />

can also be used on multiple <strong>pump</strong> installations to prevent the <strong>pump</strong>s from starting<br />

simultaneously. It is accomplished by the use of an adjustable timer supplied in all<br />

<strong>controller</strong>s except the lead <strong>controller</strong>.<br />

Dual meter; Tachometer & voltmeter<br />

EN12845:2004<br />

When this option is selected the <strong>controller</strong> shall be designed to meet the<br />

requirements for EN12845:2004. A different crank cycle is enabled, and the duty<br />

selector switch is omitted.<br />

Engine oil pressure gauge<br />

Engine water temperature gauge<br />

Engine tachometer<br />

0 to 4000rpm door mounted instrument.<br />

Battery voltmeter and selector switch<br />

Anti-condensation heater<br />

When the <strong>controller</strong> is to be used in adversely low temperature conditions, this<br />

option will maintain a safe temperature for the <strong>controller</strong> to continue operating<br />

reliably.<br />

H1 Auxiliary channel 1<br />

Close to alarm multi-purpose alarm channel<br />

H2 Auxiliary channel 2<br />

LPS<br />

R1<br />

M<br />

S<br />

T1<br />

T3<br />

Y<br />

U1<br />

W<br />

See description on previous page<br />

AC Monitoring (Lamp and remote)<br />

Comprises of a mains on indicator, and a set of volt free contacts.<br />

Low oil pressure & High water temperature alarms<br />

Close to alarm engine monitoring channels, with a pre-set 10 second delay.<br />

Engine Stop timer<br />

Manually adjustable timer with door mounted push button. For engines fitted with<br />

an energise to stop solenoid.<br />

Mounting Lugs<br />

Plinth<br />

12 Channel expansion annunciator<br />

This option provides an extra 12 channel annunciator, with 8 additional volt free<br />

outputs.<br />

Pressure Switch<br />

Externally mounted adjustable pressure switch.<br />

IP65 Weather proof enclosure<br />

Website: www.metroninc.com