FOREWORD - Central Pollution Control Board

FOREWORD - Central Pollution Control Board

FOREWORD - Central Pollution Control Board

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

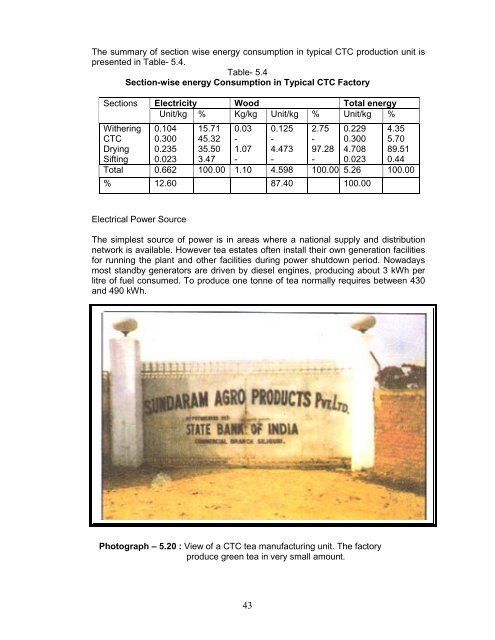

The summary of section wise energy consumption in typical CTC production unit is<br />

presented in Table- 5.4.<br />

Table- 5.4<br />

Section-wise energy Consumption in Typical CTC Factory<br />

Sections<br />

Electricity Wood Total energy<br />

Unit/kg % Kg/kg Unit/kg % Unit/kg %<br />

Withering<br />

CTC<br />

Drying<br />

Sifting<br />

0.104<br />

0.300<br />

0.235<br />

0.023<br />

15.71<br />

45.32<br />

35.50<br />

3.47<br />

0.03<br />

-<br />

1.07<br />

-<br />

0.125<br />

-<br />

4.473<br />

-<br />

2.75<br />

-<br />

97.28<br />

-<br />

0.229<br />

0.300<br />

4.708<br />

0.023<br />

4.35<br />

5.70<br />

89.51<br />

0.44<br />

Total 0.662 100.00 1.10 4.598 100.00 5.26 100.00<br />

% 12.60 87.40 100.00<br />

Electrical Power Source<br />

The simplest source of power is in areas where a national supply and distribution<br />

network is available. However tea estates often install their own generation facilities<br />

for running the plant and other facilities during power shutdown period. Nowadays<br />

most standby generators are driven by diesel engines, producing about 3 kWh per<br />

litre of fuel consumed. To produce one tonne of tea normally requires between 430<br />

and 490 kWh.<br />

-45-<br />

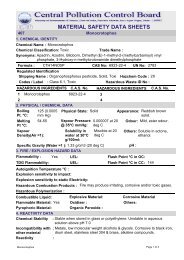

Photograph – 5.20 : View of a CTC tea manufacturing unit. The factory<br />

produce green tea in very small amount.<br />

43