The Use of a Vickers Indenter in Depth Sensing Indentation for ...

The Use of a Vickers Indenter in Depth Sensing Indentation for ...

The Use of a Vickers Indenter in Depth Sensing Indentation for ...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

486 Franco et al. Materials Research<br />

Table 1 shows the ma<strong>in</strong> test<strong>in</strong>g conditions.<br />

In all cases the <strong>in</strong>dentation depth did not surpass 10%<br />

<strong>of</strong> the specimen thickness (film or substrate), avoid<strong>in</strong>g any<br />

contribution from the substrate 22 .<br />

3.2. Materials<br />

(a)<br />

<strong>The</strong> materials used <strong>in</strong> this study were chosen <strong>in</strong> order to<br />

<strong>in</strong>clude a wide range <strong>of</strong> hardness and elastic modulus values:<br />

PVD TiN and HVOF WC-12%Co coat<strong>in</strong>gs, alum<strong>in</strong>a,<br />

AISI D2 and AISI H13 tool steels, AISI 316 sta<strong>in</strong>less steel,<br />

alum<strong>in</strong>um, gold, soda-lime glass, Au-12%Pt and Co-25%Cr<br />

odontological alloys. Table 2 presents elastic moduli <strong>for</strong><br />

these materials reported <strong>in</strong> the literature.<br />

Bulk specimens were mechanically polished and f<strong>in</strong>ished<br />

until 1 µm diamond paste. <strong>The</strong> AISI H13 tool steel specimens<br />

coated with TiN and with WC - 12%Co were carefully<br />

cleaned us<strong>in</strong>g an ultra-sound apparatus <strong>in</strong> alcohol bath<br />

and subsequently dried <strong>in</strong> warm air. <strong>The</strong> WC-12%Co coat<strong>in</strong>g<br />

thickness is about 300 µm, while the TiN coat<strong>in</strong>g thickness<br />

is about 5 µm.<br />

3.3. Analytical procedure used by Fischerscope equipment<br />

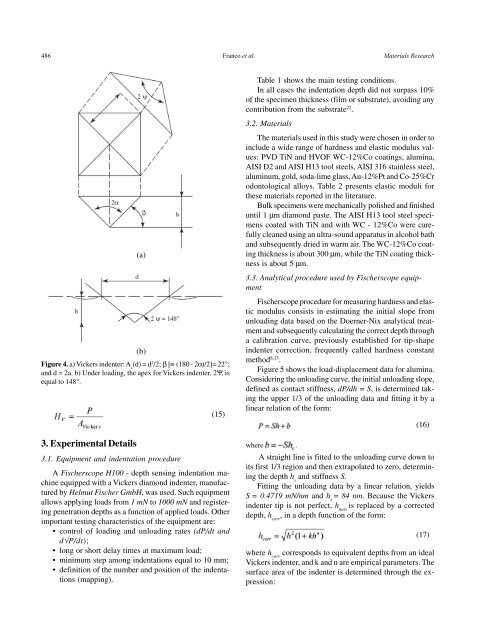

Figure 4. a) <strong>Vickers</strong> <strong>in</strong>denter: A c<br />

(d) = d 2 /2; β [≡ (180 - 2α)/2]= 22°;<br />

and d = 2a. b) Under load<strong>in</strong>g, the apex <strong>for</strong> <strong>Vickers</strong> <strong>in</strong>denter, 2Ψ, is<br />

equal to 148°.<br />

3. Experimental Details<br />

(15)<br />

3.1. Equipment and <strong>in</strong>dentation procedure<br />

A Fischerscope H100 - depth sens<strong>in</strong>g <strong>in</strong>dentation mach<strong>in</strong>e<br />

equipped with a <strong>Vickers</strong> diamond <strong>in</strong>denter, manufactured<br />

by Helmut Fischer GmbH, was used. Such equipment<br />

allows apply<strong>in</strong>g loads from 1 mN to 1000 mN and register<strong>in</strong>g<br />

penetration depths as a function <strong>of</strong> applied loads. Other<br />

important test<strong>in</strong>g characteristics <strong>of</strong> the equipment are:<br />

• control <strong>of</strong> load<strong>in</strong>g and unload<strong>in</strong>g rates (dP/dt and<br />

d√ P/dt);<br />

• long or short delay times at maximum load;<br />

• m<strong>in</strong>imum step among <strong>in</strong>dentations equal to 10 mm;<br />

• def<strong>in</strong>ition <strong>of</strong> the number and position <strong>of</strong> the <strong>in</strong>dentations<br />

(mapp<strong>in</strong>g).<br />

(b)<br />

Fischerscope procedure <strong>for</strong> measur<strong>in</strong>g hardness and elastic<br />

modulus consists <strong>in</strong> estimat<strong>in</strong>g the <strong>in</strong>itial slope from<br />

unload<strong>in</strong>g data based on the Doerner-Nix analytical treatment<br />

and subsequently calculat<strong>in</strong>g the correct depth through<br />

a calibration curve, previously established <strong>for</strong> tip-shape<br />

<strong>in</strong>denter correction, frequently called hardness constant<br />

method 8,13 .<br />

Figure 5 shows the load-displacement data <strong>for</strong> alum<strong>in</strong>a.<br />

Consider<strong>in</strong>g the unload<strong>in</strong>g curve, the <strong>in</strong>itial unload<strong>in</strong>g slope,<br />

def<strong>in</strong>ed as contact stiffness, dP/dh = S, is determ<strong>in</strong>ed tak<strong>in</strong>g<br />

the upper 1/3 <strong>of</strong> the unload<strong>in</strong>g data and fitt<strong>in</strong>g it by a<br />

l<strong>in</strong>ear relation <strong>of</strong> the <strong>for</strong>m:<br />

(16)<br />

where .<br />

A straight l<strong>in</strong>e is fitted to the unload<strong>in</strong>g curve down to<br />

its first 1/3 region and then extrapolated to zero, determ<strong>in</strong><strong>in</strong>g<br />

the depth h s<br />

and stiffness S.<br />

Fitt<strong>in</strong>g the unload<strong>in</strong>g data by a l<strong>in</strong>ear relation, yields<br />

S = 0.4719 mN/nm and h s<br />

= 84 nm. Because the <strong>Vickers</strong><br />

<strong>in</strong>denter tip is not perfect, h max<br />

is replaced by a corrected<br />

depth, h corr<br />

, <strong>in</strong> a depth function <strong>of</strong> the <strong>for</strong>m:<br />

(17)<br />

where h corr<br />

corresponds to equivalent depths from an ideal<br />

<strong>Vickers</strong> <strong>in</strong>denter, and k and n are empirical parameters. <strong>The</strong><br />

surface area <strong>of</strong> the <strong>in</strong>denter is determ<strong>in</strong>ed through the expression: