Download - Norton

Download - Norton

Download - Norton

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

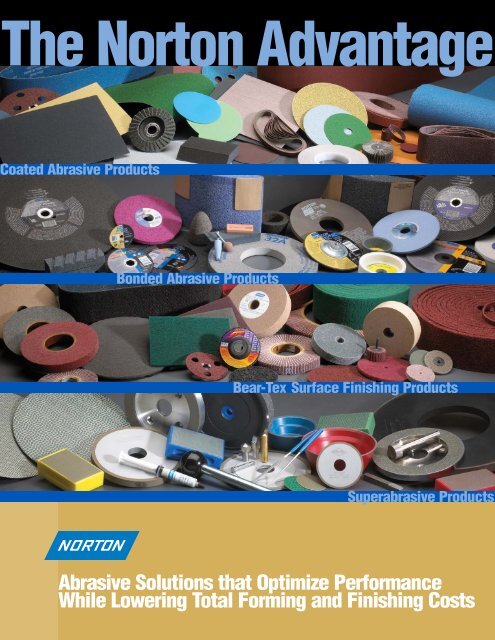

The <strong>Norton</strong> Advantage<br />

oated Abrasive Products<br />

Bonded Abrasive Products<br />

Bear-Tex<br />

®<br />

Surface Finishing Products<br />

Superabrasive Products<br />

Abrasive Solutions that Optimize Performance<br />

While Lowering Total Forming and Finishing Costs

The One Source You Can Depend on<br />

for World-Class Abrasive Solutions<br />

The <strong>Norton</strong> brand of abrasives has achieved a world leadership position in the industrial marketplace by combining<br />

high performance abrasive products with superior technical application engineering. Whether you are competing in<br />

the international marketplace or just looking to improve your bottom line, <strong>Norton</strong> can be your source for the most<br />

cost-effective grinding solutions.<br />

Your ROI depends on getting the most out of your machine tools, maximizing the performance of your operators<br />

and reducing wasteful rework. By utilizing <strong>Norton</strong> know-how and our superior full line of abrasive products, you can<br />

lower your grinding cost while raising your productivity.<br />

Superior Customer Service<br />

The <strong>Norton</strong> brand is supported by the industry’s most knowledgeable and service-oriented network of local<br />

industrial distributors. Your local distributor can help you lower your cost of purchasing abrasives by utilizing the<br />

most advanced forms of communication, including our exclusive Abrasive Connection on the Internet and EDI, to<br />

conduct business with you. You can depend on your local <strong>Norton</strong> distributor to get you the products you need when<br />

you need them.<br />

Advanced Research and Development<br />

As a member of the Saint-Gobain family of abrasives, <strong>Norton</strong> is committed to continually improving the<br />

performance of your products through ongoing research and development. As part of our commitment to providing<br />

customers with the most effective solutions, your <strong>Norton</strong> representative can also provide abrasives from many of<br />

the other superior Saint-Gobain Abrasives product lines, including Universal, Winter, Merit and Wheel Dresser.<br />

www.nortonabrasives.com

Looking for Savings?<br />

Look to <strong>Norton</strong> Advanced Technology.<br />

New Vortex Wheels<br />

Revolutionary Porous Grinding Technology<br />

With its high performance, engineered fused alumina grain and<br />

optimum three-dimensional grain spacing, Vortex technology produces<br />

a permeable grinding wheel with very high metal removal rates, longer<br />

wheel life, and ultimate part quality. Dramatically reduced wheel<br />

dressing and cycle times, and consistent performance throughout the<br />

life of the wheel, result in maximum productivity and lowest total costs<br />

for difficult-to-grind, heat-sensitive operations.<br />

Max Q' [(in3/min)/in]<br />

2.5<br />

2.0<br />

1.5<br />

1.0<br />

0.5<br />

Q' at Burn Initiation vs. Dress Comp.<br />

HGTC Grinding results-Test 2.1795<br />

VORTEX Technology<br />

Standard Product<br />

0.0<br />

0 10 20 30 40 50 60 70<br />

Dress Comp (µin/rev)<br />

New <strong>Norton</strong> Neptune X10 Technology<br />

30-50% Longer Wheel Life AND<br />

Superior Quality Components<br />

Neptune wheels with X10 Technology nearly<br />

eliminate softening under flood coolant<br />

conditions, resulting in a more consistent<br />

performance and less need to adjust<br />

machine set-up.<br />

HIGHER PERFORMANCE<br />

STEADY STATE<br />

STEADY STATE<br />

INCREASED GRINDING TIME IN COOLANT<br />

X10 TECHNOLOGY<br />

Grinding Behavior as a Function of Time in Coolant<br />

STANDARD<br />

TwinStar and TwinFiber Ceramic Flap Discs<br />

Grind and Finish in One Operation<br />

Their blend of premium ceramic and aluminum oxide<br />

abrasives creates the industry's top performing flap<br />

discs on stainless and carbon steel applications.<br />

Conical TwinFiber discs are ideal for maximum stock<br />

removal. Flat TwinStar discs excel at fine finishing.<br />

NORaX Engineered Abrasive Belts<br />

Generate a Better Finish… More Economically<br />

NORaX U242 belts are an example of the advanced abrasive technology<br />

only available from <strong>Norton</strong>. The engineered, multi-layered surface<br />

pattern outlasts conventional polishing belts, cuts faster and produces a<br />

repeatable, consistent finish from the first to last part. NORaX U242<br />

belts last 2-5 times longer than conventional abrasive belts.<br />

Two Basic Flap Disc Designs<br />

15° – 25°<br />

Type 29 – Conical<br />

Grind at steeper angles for<br />

more aggressive applications.<br />

0° – 15°<br />

Type 27 – Flat<br />

Grind at flatter angles for<br />

the best finish.<br />

<strong>Norton</strong> SG Abrasive Belts and Discs<br />

Patented SG Technology<br />

Increases Productivity and<br />

Lowers Grinding Cost<br />

We continually refine our SG ceramic<br />

products to provide the highest level of<br />

performance and lowest total sanding<br />

cost, reduce downtime, reduce<br />

inventory, and reduce disposal costs.<br />

Abrasive Analysis of <strong>Norton</strong> SG vs. Premium Aluminum Oxide Belt After Three Hours<br />

GRAIN<br />

SHARPNESS<br />

GRAIN<br />

FAILURE<br />

GRAINS<br />

REMAINING<br />

SHARP<br />

GRAINS<br />

FRACTURING<br />

PREMATURELY<br />

GRAINS<br />

WORN<br />

FLAT<br />

0%<br />

3%<br />

2%<br />

GRAIN GRAINS<br />

REMAINING<br />

ENDURANCE SHARP<br />

As a test of endurance, this <strong>Norton</strong> SG belt ran for seven days and was still cutting.<br />

It was removed only for analysis and comparison.<br />

66%<br />

95%<br />

34% Aluminum Oxide Belt<br />

<strong>Norton</strong> SG Belt<br />

Abrasive Analysis of <strong>Norton</strong> SG Belt after Seven Days (Eight Hour Shifts)<br />

91%

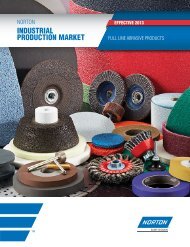

The Most Complete Line of Stock<br />

and Engineered Abrasives<br />

The <strong>Norton</strong> line of abrasives includes conventional and superabrasive grinding products, sanding belts, discs, sheets and<br />

specialty items, diamond dressing tools, devices and non-woven fiber products. To help you obtain the most appropriate<br />

product, based on your application and price, <strong>Norton</strong> stock products are available in up to three performance levels. The<br />

complete stock availability can be accessed online at www.nortonabrasives.com.<br />

If your application requires custom engineered products, you can rely on your <strong>Norton</strong> representative to help engineer the<br />

most cost-effective specification by utilizing our advanced machine tool monitoring systems.<br />

New from<br />

Coated Abrasives<br />

❚ Expanded offering of ceramic/<br />

zirconia and new aluminum oxide<br />

R265 flap discs<br />

❚ GreenLyte Plus F986 ceramic<br />

Speed-Lok discs<br />

❚ PSA split liner paper discs<br />

❚ No-Fil Multi-Air Speed-Grip (hook<br />

and loop) paper discs<br />

❚ Tufbak waterproof paper discs for<br />

metallurgical analysis<br />

❚ NORaX U288 film discs<br />

❚ SoftTouch contour sponges<br />

<strong>Norton</strong><br />

Surface Finishing Products<br />

❚ Performance improvements to all hand pads<br />

and new, perforated and Food Pro pads<br />

❚ Four new, comprehensive specifications of<br />

Bear-Tex surface blending belts and discs<br />

Bonded Abrasives<br />

❚ BEST, BETTER and imported GOOD<br />

depressed center wheel lines, including<br />

3X FLEX Type 29<br />

❚ RightCut thin depressed center and<br />

straight right angle grinder cut-off<br />

wheels<br />

❚ 9" - 14" metallurgical cut-off wheels<br />

Electroplated<br />

Diamond<br />

Products<br />

❚ Flexible diamond PSA<br />

and Speed-Lok TR discs<br />

To put <strong>Norton</strong> abrasives to work, contact your local <strong>Norton</strong> distributor. Call 1-800-446-1119 or email us at buynorton@nortonabrasives.com and<br />

we’ll put you in contact with your local <strong>Norton</strong> industrial distributor. Or, visit our website at www.nortonabrasives.com to view our online catalog and<br />

learn about our latest products and applications.<br />

Your Source For Cost Saving Abrasive Solutions <br />

HEADQUARTERS:<br />

Saint-Gobain Abrasives, Inc.<br />

1 New Bond Street<br />

Worcester, MA 01615-0008<br />

Telephone: 1 800 446-1119<br />

CUSTOMER SERVICE U.S.:<br />

Saint-Gobain Abrasives, Inc.<br />

2770 West Washington Street<br />

Stephenville, TX 76401-3799<br />

Phone: (254) 918-2313<br />

Fax: (254) 918-2314<br />

CUSTOMER SERVICE CANADA:<br />

Saint-Gobain Abrasives Canada Inc.<br />

PO Box 3008, 3 Beach Road<br />

Hamilton, ON L8L 7Y5<br />

Phone: (905) 547-2551<br />

Fax: (905) 547-8157<br />

www.nortonabrasives.com<br />

© Saint-Gobain Abrasives, Inc. June 2005<br />

Bear-Tex, No-Fil, NORaX, the <strong>Norton</strong> logo, <strong>Norton</strong> SG, Speed-Grip, Speed-Lok and Tufbak are<br />

registered trademarks and 3X Flex, Food Pro, GreenLyte, Multi-Air, Neptune, RightCut, SoftTouch,<br />

TwinFiber, TwinStar, X10 Technology and Vortex are trademarks of Saint-Gobain Abrasives, Inc.<br />

form #7816