Chamber/Anilox System - Harris & Bruno

Chamber/Anilox System - Harris & Bruno

Chamber/Anilox System - Harris & Bruno

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Q: Can I specify this equipment on my new press purchase?<br />

A: This system can be ordered through the press manufacturer on a new machine or purchased as a<br />

retrofit to an existing press.<br />

Q: On what Offset press types can this unit be installed?<br />

A: The H&B LithoCoat system has been installed on most popular machine types, including: Komori,<br />

Mitsubishi, Heidelberg, MAN Roland, KBA Planeta, Sakurai, and others.<br />

FAQ’s<br />

Q: I have an add-on blanket coater, can this be converted to the LithoCoat technology?<br />

A: In most cases an existing blanket coater can be converted to include a ceramic anilox roll and the<br />

chambered doctor blade system. Improvements in performance along with faster clean-ups and less<br />

slinging can be expected.<br />

Q: What is an anilox roll?<br />

A: The anilox roll is simply a metering roll designed to consistently supply a uniform and measurable<br />

volume of liquid. Using a computer-controlled laser, millions of microscopic holes (or cells) are vaporized<br />

into the surface of the ceramic coating of the anilox roll. These cells are what actually cups and carries<br />

the coating to the blanket or plate cylinder.<br />

Q: What rolls are removed and how is the new anilox driven?<br />

A: The smooth chrome or rubber application roll presently in the press is removed and replaced with<br />

anilox roll of exactly the same physical dimensions. Depending on press type, split cap journals are<br />

installed to speed future roll changes. The existing press drive is re-used to maintain an exact surface<br />

speed match between the new anilox roll and the blanket cylinder. All of the other transfer rolls in the<br />

coater are removed.<br />

Q: Can I run with just one anilox roll or do I need to change rolls with every coating?<br />

A: A typical printer will usually require one roll that can be run with all of their coatings. However, if<br />

major variances in coating weight are required (example: switching from a flood work and turn to a<br />

blister coating) an additional roll with a different engraving may be required. A spare roll is also smart to<br />

have on hand.<br />

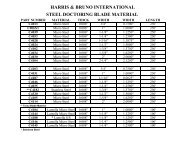

Q: I hear of steel, aluminum, carbon fiber, chrome & ceramic anilox rolls. What’s the best choice?<br />

A: The core of the anilox roll can be made of steel or lighter-weight aluminum and carbon fiber. The<br />

downside to carbon fiber is a higher cost. Aluminum is half the cost of carbon fiber, can be re-engraved<br />

more times than carbon fiber, and is still light enough to be lifted without a hoist. All cores are ceramic<br />

coated and then laser engraved to exact specifications for the application. Mechanically engraved<br />

chrome rolls were used in the past, but industry experts agree that ceramic offers superior performance,<br />

accuracy and wear resistance. H&B only uses ceramic surface rolls.<br />

Q: How do I determine the proper anilox volume?<br />

A: As part of the complete package, H&B guarantees to supply the proper anilox roll for the application.<br />

We also offer the use of banded rolls (rolls with different volumes) to help in testing and ultimately<br />

deciding what the exact engraving should be.<br />

United United United States: States: 8555 Washington Blvd. ● Roseville, CA 95678 ● Phone 916-781-7676 ● Fax 916-781-3645 ● www.harris-bruno.com<br />

Europe: Europe: Auf der Hohe 15 ● 73529 Schwabisch Gmund ● Germany ● Phone +49-7171-94704-0 ● Fax +49-7171-94704-20 ● www.harris-bruno.de<br />

Japan: Japan: 2-8-26-201 Ushikubo Higashi ● Tsuzuki-ward ● Yokohama-city ● Kanagawa-pref. 224-0014 ● Phone +81-(0)45-264-7555<br />

Regional Offices Worldwide