You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Addressing PID Sensor Moisture Sensitivity<br />

Technical Note TN-163<br />

rev 5 ab.05-07<br />

The RAE Systems’ photoionization detectors (<strong>PIDs</strong>)<br />

were designed to have little or no response to<br />

moisture. However, when the sensor is dirty, bent<br />

out of shape, or corroded, RAE Systems’ monitors<br />

may show a strong response to humidity at or above<br />

about 85% RH (relative humidity).<br />

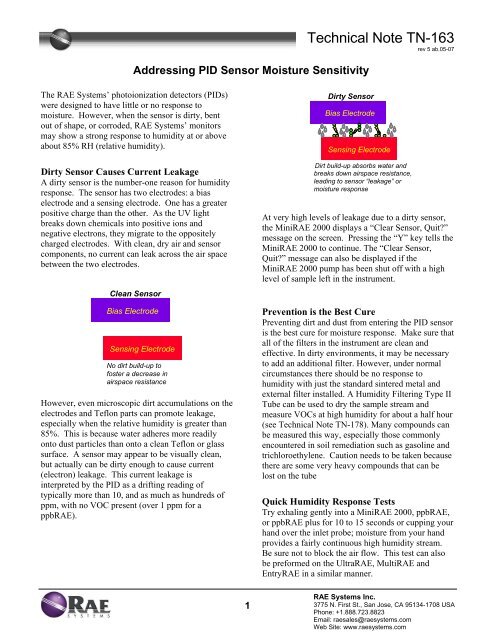

Dirty Sensor Causes Current Leakage<br />

A dirty sensor is the number-one reason for humidity<br />

response. The sensor has two electrodes: a bias<br />

electrode and a sensing electrode. One has a greater<br />

positive charge than the other. <strong>As</strong> the UV light<br />

breaks down chemicals into positive ions and<br />

negative electrons, they migrate to the oppositely<br />

charged electrodes. With clean, dry air and sensor<br />

components, no current can leak across the air space<br />

between the two electrodes.<br />

Clean Sensor<br />

Bias Electrode<br />

Sensing Electrode<br />

No dirt build-up to<br />

foster a decrease in<br />

airspace resistance<br />

However, even microscopic dirt accumulations<br />

on the<br />

electrodes and Teflon parts can promote leakage,<br />

especially when the relative humidity is greater than<br />

85%. This is because water adheres more readily<br />

onto dust particles than onto a clean Teflon or glass<br />

surface. A sensor may appear to be visually clean,<br />

but actually can be dirty enough to cause current<br />

(electron) leakage. This current leakage is<br />

interpreted by the PID as a drifting reading of<br />

typically more than 10, and as much as hundreds of<br />

ppm, with no VOC present (over 1 ppm for a<br />

ppbRAE).<br />

Dirty Sensor<br />

Bias Electrode<br />

Sensing Electrode<br />

Dirt build-up absorbs water and<br />

breaks down airspace resistance,<br />

leading to sensor “ leakage” or<br />

moisture response<br />

At very high levels of leakage due to a dirty sensor,<br />

the MiniRAE 2000 displays a “Clear Sensor, Quit?”<br />

message on the screen. Pressing the “Y” key tells the<br />

MiniRAE 2000 to continue. The “Clear Sensor,<br />

Quit?” message can also be displayed if the<br />

MiniRAE 2000 pump has been shut off with a high<br />

level of sample left in the instrument.<br />

Prevention is the Best Cure<br />

Preventing dirt and dust from entering the PID sensor<br />

is the best cure for moisture response. Make sure that<br />

all of the filters in the instrument are clean and<br />

effective. In dirty environments, it may be necessary<br />

to add an additional filter. However, under normal<br />

circumstances there should be no response to<br />

humidity with just the standard sintered metal and<br />

external filter installed. A Humidity Filtering Type II<br />

Tube can be used to dry the sample stream and<br />

measure VOCs at high humidity for about a half hour<br />

(see Technical Note TN-178). Many compounds can<br />

be measured this way, especially those commonly<br />

encountered in soil remediation such as gasoline and<br />

trichloroethylene. Caution needs to be taken because<br />

there are some<br />

very heavy compounds that can be<br />

lost on the tube<br />

Quick Humidity <strong>Response</strong> Tests<br />

Try exhaling gently into a MiniRAE 2000, ppbRAE,<br />

or ppbRAE plus for 10 to 15 seconds or cupping your<br />

hand over the inlet probe; moisture from your hand<br />

provides a fairly continuous high humidity stream.<br />

Be sure not to block the air flow. This test can also<br />

be preformed on the UltraRAE, MultiRAE and<br />

EntryRAE in a similar manner.<br />

1<br />

RAE Systems Inc.<br />

3775 N. First St., San Jose, CA 95134-1708 USA<br />

Phone: +1.888.723.8823<br />

Email: raesales@raesystems.com<br />

Web Site: www.raesystems.com

Technical Note TN-163<br />

rev 5 ab.05-07<br />

inside the probe, including a green dust filter and a<br />

white<br />

“C” filter. Both of these should be removed.<br />

The instrument should show little or no response<br />

from these tests. If the MiniRAE 2000 shows more<br />

than 5 ppm isobutylene units or the ppbRAE shows<br />

more than 500 ppb increase in reading, then<br />

something is wrong. The design of the instruments<br />

makes it quick and easy to remove and clean the<br />

probe, lamp, and sensor to address this problem.<br />

Focus on the following areas:<br />

1. Replace filters<br />

2. Clean the probe, PID lamp, and sensor<br />

3. Inspect the sensor for damage or corrosio n.<br />

4. Clean the sensor housing.<br />

5. Clean the sensor using an ultrasonic bath.<br />

MiniRAE 2000, ppbRAE Plus, and UltraRAE<br />

When testing the UltraRAE monitor, make sure that the<br />

tube of interest is installed before proceeding with the<br />

test. If you plan to test for Benzene, install the Benzene<br />

tube and use the same moisture test discussed for the<br />

MiniRAE 2000. If the readings increase more than 2<br />

ppm Benzene units, then there is a problem with dirt in<br />

the monitor.<br />

Replace Filter<br />

The MiniRAE 2000, ppbRAE, ppbRAE plus, and<br />

UltraRAE all use two filters, an external filter and a<br />

sintered metal filter. The external filter (PN 002-<br />

3022-005 for a pack of 5, 002-3022-010 for a pack of<br />

10, and PN 002-3022-100 for a pack of 100) is<br />

attached to the end of the probe and is white. If it<br />

appears to have any discoloration, then it is time to<br />

replace the filter. If the instrument goes into pump<br />

alarm with the filter attached and is able to run<br />

without any problems when not attached, it is time to<br />

replace the filter. When the instrument is responding<br />

to moisture, it is time to replace the filter. The metal<br />

sintered filter (PN 490-0047-005 for a pack of 5)<br />

should be replaced when it is dirty and when the<br />

instrument responds to moisture. The MiniRAE<br />

2000 and ppbRAE instruments have other filters<br />

Clean the Probe<br />

Unscrew the lamp housing cap; inspect the sintered<br />

metal filter at the bottom of the probe. If it appears to<br />

be dirty, it needs to be replaced. A dirty internal filter<br />

indicates that the probe has dirt inside and requires<br />

cleaning. Cleaning the probe depends on the kind of<br />

exposure or dirt that has contaminated the probe. If it is<br />

a chemical that might affect the reading of the PID, use<br />

methanol to clean the probe. If it is just dirt or dust that<br />

has been sucked into the instrument, blow clean, dry air<br />

through the probe to clear the internal tubing.<br />

Clean the PID Lamp<br />

Access to both the lamp and the sensor of a MiniRAE<br />

2000 and ppbRAE plus requires no tools. To remove<br />

the PID sensor, grasp the top lip of the sensor and pull<br />

straight out, to avoid bending the electrical pins on the<br />

sensor. If the sensor does not pull out immediately, a<br />

gentle rocking motion should help loosen the sensor.<br />

Also try rotating your grip as you pull the sensor. Once<br />

the PID sensor is removed, set it aside to clean or to<br />

inspect for damage or corrosion.<br />

The PID lamp has a white O-ring that keeps it from<br />

sitting too low in the lamp housing. Before reaching for<br />

the lamp, get out the lamp cleaning kit (PN 081-0002-<br />

000), which includes methanol, finger cots, cotton<br />

swabs, and lens tissue. Use finger cots on the fingers<br />

that will handle the lamp.<br />

CAUTION: Never touch the window surface with<br />

anything that might scratch, including your fingers, or<br />

any liquid that might leave a film.<br />

Carefully remove the lamp by grabbing onto the white<br />

O-ring, and set the instrument aside. Dip a cotton swab<br />

into the methanol and wipe the window surface of the<br />

lamp. The sides of the lamp can be cleaned if it is<br />

obviously dirty, but the flat-surface window of the lamp<br />

is the only part of the PID lamp that requires cleaning.<br />

Once the lamp is cleaned, use a piece of the lens tissue<br />

to dry and polish the lamp before dropping it back into<br />

the instrument. If there is visible dirt, clean the lamp<br />

housing prior to placing the lamp back into the<br />

instrument. Do not force the lamp all the way down to<br />

the bottom of the lamp housing. Allow the PID sensor<br />

to push the lamp the rest of the way into place.<br />

2<br />

RAE Systems Inc.<br />

3775 N. First St., San Jose, CA 95134-1708 USA<br />

Phone: +1.888.723.8823<br />

Email: raesales@raesystems.com<br />

Web Site: www.raesystems.com

Technical Note TN-163<br />

rev 5 ab.05-07<br />

To access the UltraRAE lamp for cleaning, you will<br />

need to first remove any RAE-SEP tube from the probe.<br />

Then unscrew the four screws holding the bar code<br />

reader cap to the instrument base. Lift the Bar Code<br />

Reader cap straight off of the instrument base until the<br />

PCB (printed circuit board) clears. Set it aside and<br />

make sure that the screws do not fall out and disappear.<br />

Take the silver sensor adapter off of the PID senso r.<br />

Underneath is a rubber tube connector and a silver<br />

sintered filter. Remove the rubber tube connector with<br />

filter. If it appears to be dirty, it needs to be replaced. A<br />

dirty internal filter indicates that the probe has dirt<br />

inside and requires cleaning. Cleaning the probe<br />

depends on the kind of exposure or dirt that has<br />

contaminated the probe. If it is a chemical that might<br />

affect the reading of the PID, use methanol to clean the<br />

probe. If it is just dirt or dust that has been sucked into<br />

the instrument, blow clean, dry air through the probe to<br />

clear the internal tubing.<br />

bent or the Teflon mask is warped, the sensor needs<br />

replacement. Note: A warped Teflon mask can be a<br />

sign that the sensor has been exposed to too much heat.<br />

Straight Electrodes<br />

with mask removed<br />

for clarity<br />

Good Sensor<br />

(partly disassembled)<br />

Warped<br />

Teflon<br />

Mask<br />

Damaged Sensor<br />

Bent<br />

Electrode<br />

If the sensing electrode is exposed to UV light from the<br />

lamp, it gives an undesired positive response to the<br />

light. If the fingers look aligned but are not in the same<br />

plane (some fingers are bent towards or away from the<br />

lamp), then the sensor should be replaced. The fingers<br />

should be close to, but not touching, the Teflon mask.<br />

In some cases it is possible to carefully bend the<br />

electrodes back into the correct position if the damage is<br />

very minor.<br />

Clean the Sensor Housing<br />

If the PID sensor is not damaged, thoroughly wipe clean<br />

the sensor housing area using a cotton swab dipped in<br />

lamp-cleaning methanol. Let the sensor housing area<br />

dry completely. Reassemble the PID, and perform a<br />

humidity response test. If it shows no response,<br />

calibrate the instrument and return it to service.<br />

Follow the directions for the MiniRAE 2000 and<br />

ppbRAE plus for PID sensor and lamp removal. The<br />

UltraRAE PID sensor and lamp are the same as those in<br />

the MiniRAE 2000.<br />

Sensor<br />

Housing<br />

Inspect the Sensor for Damage or Corrosion<br />

If the sensor appears corroded, it should be replaced. If<br />

the sensor is damaged or even slightly bent, it can show<br />

increased response to moisture. The bias and sensing<br />

electrodes are two sets of “fingers” in the MiniRAE<br />

2000 sensor. These fingers should be straight and<br />

parallel. The bias electrode is easy to see when the<br />

bottom of the sensor is inspected. However, the sensing<br />

electrode should be blocked from sight (and the UV<br />

light from the PID lamp) by a Teflon mask. If the<br />

sensing electrode can be seen because the fingers are<br />

Cleaning the PID Sensor<br />

Cleaning the lamp and sensor surfaces using the lamp<br />

cleaning kit with cotton swabs is not good enough to<br />

remove humidity response. In fact, cotton swabs can<br />

leave behind fibers that continue to cause moisture<br />

issues after cleaning. An ultrasonic cleaning bath<br />

MUST be used. Ultrasonic cleaners are available<br />

from laboratory suppliers. Alternatively, a jewelry<br />

3<br />

RAE Systems Inc.<br />

3775 N. First St., San Jose, CA 95134-1708 USA<br />

Phone: +1.888.723.8823<br />

Email: raesales@raesystems.com<br />

Web Site: www.raesystems.com

Technical Note TN-163<br />

rev 5 ab.05-07<br />

cleaner from a department store can be used. To<br />

clean the sensor, remove it from the instrument<br />

and<br />

immerse it in lamp-cleaning solution (anhydrous<br />

methanol) in a small beaker or baby food jar. Fill the<br />

ultrasonic cleaning bath with water. Place the beaker<br />

containing the sensor into the water bath of the<br />

ultrasonic cleaner. The ultrasonic waves pass through<br />

the water and container and assist in cleaning the<br />

sensor. The lamp-cleaning solution in the jar can be<br />

reused a few times until it becomes dirty. Remove the<br />

through the tube easily. Some heavy vapors such as<br />

diesel fuel or polar compounds such as acetone and<br />

alcohols require extended sampling times. See<br />

Technical Note TN-178 for more details and cautions<br />

on use. (Note that Type I Humidity Filtering tubes<br />

cannot be used during measurements.)<br />

Flex-I-Probe<br />

Tube Tip Breaker<br />

(p/n 021-2400-100)<br />

Tube Adapter<br />

(p/n 025-3002-000)<br />

Humidity Filtering II Tube<br />

(10-pack, p/n 025-2002-010)<br />

Water Bath<br />

Methanol<br />

in Jar<br />

Ultrasonic Cleaner<br />

sensor and allow it to dry for at least a few hours, and<br />

preferably overnight (warm but not hot air will speed<br />

the drying process).<br />

Caution! Do not overheat the sensor, and never<br />

disassemble the sensor!<br />

It is very important to blow or shake out any residual<br />

lamp-cleaning solution from the sensor before letting it<br />

air dry. Otherwise, some of the dirt that was just<br />

extracted into the cleaning solvent could be deposited<br />

back onto the sensor components as they dry.<br />

Reinstall the clean, dry sensor into the MiniRAE 2000.<br />

Exhale into the instrument and check the response. If it<br />

shows no response to the moisture in your breath,<br />

calibrate the instrument and return it to service.<br />

Using Humidity Filtering II tubes<br />

Humidity Filtering Tubes (Type II) can be used to dry<br />

the sample gas and measure many VOCs for about 15<br />

minutes to 1 hour. Their use prevents moisture effects,<br />

even on a dirty sensor. The tubes (p/n 025-2002-010)<br />

are inserted into an adapter (PN 025-3002-000) attached<br />

to a Flex-I-Probe (PN 021-2400-000). Many<br />

compounds such as trichloroethylene and gasoline pass<br />

MultiRAE Plus and EntryRAE<br />

While the MultiRAE and EntryRAE do not normally<br />

have as many issues with dirt in PID sensor,<br />

contamination is possible. The moisture test is done<br />

by cupping your hand over the end or breathing<br />

gently into the end, being careful not to block the air<br />

flow. If the VOC reading increases over 5 ppm<br />

isobutylene, there is a problem with dirt.<br />

Filters<br />

The MultiRAE uses a smaller external filter (PN 008-<br />

3022-001 for a pack of 3, PN 008-3022-010 for a<br />

pack of 10, PN 008-3022-100 for a pack of 100, and<br />

PN 008-3014-000 for a single external filter with<br />

adapter for the silver MultiRAE). This white filter<br />

should be replaced when it is dirty and when the<br />

instrument responds to moisture. If the instrument<br />

goes into pump alarm with the filter attached and is<br />

able to run without any problems when it is not<br />

attached, it is time to replace the filter.<br />

The EntryRAE uses a small external filter (PN 490-<br />

0122-000), which should be replaced when it appears<br />

dirty or when the instrument goes into pump alarm<br />

with the filter attached and clears the pump alarm<br />

when the filter is removed.<br />

MultiRAE PLUS<br />

There are two versions of the MultiRAE Plus, silver<br />

housing and black housing. There are small differences<br />

when cleaning them. If there is a response to moisture,<br />

dirt has gotten to the lamp. Due to the gas flow within<br />

the instrument, if dirt has gotten to the lamp, it has<br />

probably gotten into the filter, pump, tubing (silver<br />

MultiRAE only) and the gas plate.<br />

4<br />

RAE Systems Inc.<br />

3775 N. First St., San Jose, CA 95134-1708 USA<br />

Phone: +1.888.723.8823<br />

Email: raesales@raesystems.com<br />

Web Site: www.raesystems.com

Technical Note TN-163<br />

rev 5 ab.05-07<br />

Pump<br />

Start by replacing the filter, and then work on cleaning<br />

the internal parts of the instrument. Loosen the two<br />

screws on the back of the instrument and remove the<br />

top housing cover. Unplug the battery. If you have a<br />

black-box MultiRAE, you have access to the gas plate,<br />

pump and sensors now. If you have a silver-box<br />

MultiRAE, you still need to unscrew the four screws<br />

holding the gas plate to the instrument. After loosening<br />

the four screws, pull the gas plate off of the silver stand-<br />

plugged into the<br />

offs. Unplug the tubing from the pump and the wiring<br />

PCB.<br />

To clean the tubing, remove both pieces of tubing<br />

from<br />

the instrument and the gas plate and immerse it in<br />

methanol. Agitate it by hand or in an ultrasonic bath.<br />

Remove it and let it dry overnight. The black<br />

MultiRAE does not have tubing, but there are O-rings<br />

in the adapter attached to the tubing. Make sure there is<br />

no dirt in the adapter or O-rings by removing the pump<br />

from the top housing, and unplug the pump from the<br />

adapter. Remove all eight O-rings and inspect the<br />

adapter and O-rings. Clean the adapter and O-rings<br />

with methanol. Dry the O-rings with a piece of the lens<br />

tissue that comes with lamp-cleaning kit. Clean the<br />

pump by removing the four screws that hold the head to<br />

the diaphragm. Use a cotton swab dipped in methanol<br />

to clean all surfaces, including the diaphragm.<br />

Reassemble the pump and set it aside to dry for 5<br />

minutes. Now that everything is removed from the gas<br />

plate, clean the gas plate by pushing air or methanol<br />

through the airflow path. Allow it to dry overnight.<br />

The PID sensor<br />

The PID sensor is covered by a shielding cover that<br />

needs to be removed. This silver cover can be dipped in<br />

methanol to be cleaned. To clean the sensor, remove it<br />

from the instrument and immerse it in lamp-cleaning<br />

solution (anhydrous methanol) in a small beaker or<br />

baby food jar.<br />

Agitate it by hand or in an ultrasonic cleaner. Fill the<br />

ultrasonic cleaning bath with water. Place the beaker<br />

containing the sensor into the water bath of the<br />

ultrasonic cleaner. The ultrasonic waves pass through<br />

the water and container and assist in cleaning the<br />

sensor. The lamp-cleaning solution in the jar can be<br />

reused a few times until it becomes dirty. Remove<br />

the PID sensor and let it dry for at least a few hours,<br />

and preferably overnight (warm but not hot air will<br />

speed the drying process).<br />

Caution! Do not overheat the sensor!<br />

It is very important to blow or shake out any residual<br />

lamp-cleaning solution from the sensor before letting it<br />

air dry. Otherwise, some of the dirt that was just<br />

extracted into the cleaning solvent could be deposited<br />

back onto the sensor components as they dry. Reinstall<br />

the clean, dry sensor into the MultiRAE. Exhale into<br />

the instrument and check the response. If it shows no<br />

response to the moisture in your breath, calibrate the<br />

instrument and return it to service.<br />

EntryRAE<br />

If moisture problems still persist, contact the RAE<br />

Systems Service Department at 888-723-4800.<br />

5<br />

RAE Systems Inc.<br />

3775 N. First St., San Jose, CA 95134-1708 USA<br />

Phone: +1.888.723.8823<br />

Email: raesales@raesystems.com<br />

Web Site: www.raesystems.com