Freeze Trim - barwell

Freeze Trim - barwell

Freeze Trim - barwell

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

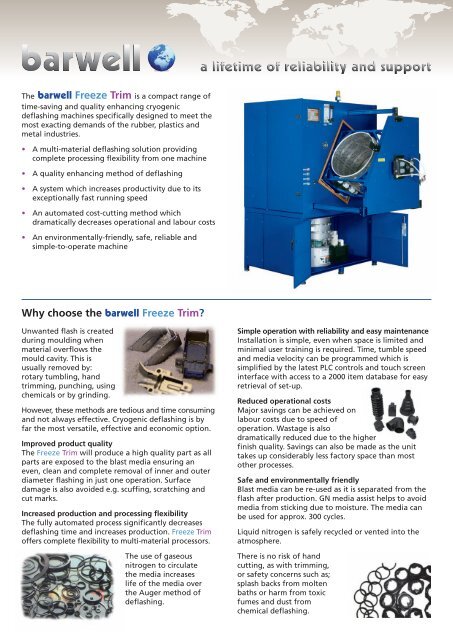

The <strong>barwell</strong> <strong>Freeze</strong> <strong>Trim</strong> is a compact range of<br />

time-saving and quality enhancing cryogenic<br />

deflashing machines specifically designed to meet the<br />

most exacting demands of the rubber, plastics and<br />

metal industries.<br />

• A multi-material deflashing solution providing<br />

complete processing flexibility from one machine<br />

• A quality enhancing method of deflashing<br />

• A system which increases productivity due to its<br />

exceptionally fast running speed<br />

• An automated cost-cutting method which<br />

dramatically decreases operational and labour costs<br />

• An environmentally-friendly, safe, reliable and<br />

simple-to-operate machine<br />

Why choose the <strong>barwell</strong> <strong>Freeze</strong> <strong>Trim</strong><br />

Unwanted flash is created<br />

during moulding when<br />

material overflows the<br />

mould cavity. This is<br />

usually removed by:<br />

rotary tumbling, hand<br />

trimming, punching, using<br />

chemicals or by grinding.<br />

However, these methods are tedious and time consuming<br />

and not always effective. Cryogenic deflashing is by<br />

far the most versatile, effective and economic option.<br />

Improved product quality<br />

The <strong>Freeze</strong> <strong>Trim</strong> will produce a high quality part as all<br />

parts are exposed to the blast media ensuring an<br />

even, clean and complete removal of inner and outer<br />

diameter flashing in just one operation. Surface<br />

damage is also avoided e.g. scuffing, scratching and<br />

cut marks.<br />

Increased production and processing flexibility<br />

The fully automated process significantly decreases<br />

deflashing time and increases production. <strong>Freeze</strong> <strong>Trim</strong><br />

offers complete flexibility to multi-material processors.<br />

The use of gaseous<br />

nitrogen to circulate<br />

the media increases<br />

life of the media over<br />

the Auger method of<br />

deflashing.<br />

Simple operation with reliability and easy maintenance<br />

Installation is simple, even when space is limited and<br />

minimal user training is required. Time, tumble speed<br />

and media velocity can be programmed which is<br />

simplified by the latest PLC controls and touch screen<br />

interface with access to a 2000 item database for easy<br />

retrieval of set-up.<br />

Reduced operational costs<br />

Major savings can be achieved on<br />

labour costs due to speed of<br />

operation. Wastage is also<br />

dramatically reduced due to the higher<br />

finish quality. Savings can also be made as the unit<br />

takes up considerably less factory space than most<br />

other processes.<br />

Safe and environmentally friendly<br />

Blast media can be re-used as it is separated from the<br />

flash after production. GN media assist helps to avoid<br />

media from sticking due to moisture. The media can<br />

be used for approx. 300 cycles.<br />

Liquid nitrogen is safely recycled or vented into the<br />

atmosphere.<br />

There is no risk of hand<br />

cutting, as with trimming,<br />

or safety concerns such as;<br />

splash backs from molten<br />

baths or harm from toxic<br />

fumes and dust from<br />

chemical deflashing.