GRC Production - OCV Reinforcements

GRC Production - OCV Reinforcements

GRC Production - OCV Reinforcements

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

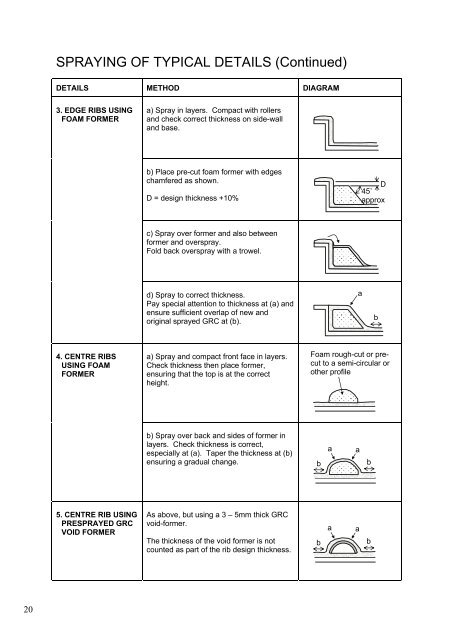

SPRAYING OF TYPICAL DETAILS (Continued)<br />

DETAILS METHOD DIAGRAM<br />

3. EDGE RIBS USING<br />

FOAM FORMER<br />

a) Spray in layers. Compact with rollers<br />

and check correct thickness on side-wall<br />

and base.<br />

b) Place pre-cut foam former with edges<br />

chamfered as shown.<br />

D = design thickness +10%<br />

D<br />

45<br />

approx<br />

c) Spray over former and also between<br />

former and overspray.<br />

Fold back overspray with a trowel.<br />

d) Spray to correct thickness.<br />

Pay special attention to thickness at (a) and<br />

ensure sufficient overlap of new and<br />

original sprayed <strong>GRC</strong> at (b).<br />

a<br />

b<br />

4. CENTRE RIBS<br />

USING FOAM<br />

FORMER<br />

a) Spray and compact front face in layers.<br />

Check thickness then place former,<br />

ensuring that the top is at the correct<br />

height.<br />

Foam rough-cut or precut<br />

to a semi-circular or<br />

other profile<br />

b) Spray over back and sides of former in<br />

layers. Check thickness is correct,<br />

especially at (a). Taper the thickness at (b)<br />

ensuring a gradual change.<br />

b<br />

a<br />

a<br />

b<br />

5. CENTRE RIB USING<br />

PRESPRAYED <strong>GRC</strong><br />

VOID FORMER<br />

As above, but using a 3 – 5mm thick <strong>GRC</strong><br />

void-former.<br />

The thickness of the void former is not<br />

counted as part of the rib design thickness.<br />

b<br />

a<br />

a<br />

b<br />

20<br />

18