Metal Removal catalog - Tyson Tool Company Limited

Metal Removal catalog - Tyson Tool Company Limited

Metal Removal catalog - Tyson Tool Company Limited

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

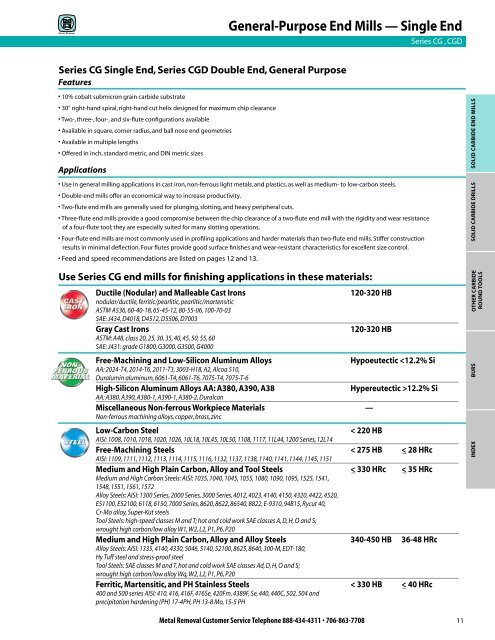

General-Purpose End Mills — Single End<br />

Series CG , CGD<br />

Series CG Single End, Series CGD Double End, General Purpose<br />

Features<br />

• 10% cobalt submicron grain carbide substrate<br />

• 30° right-hand spiral, right-hand cut helix designed for maximum chip clearance<br />

• Two-, three-, four-, and six-flute configurations available<br />

• Available in square, corner radius, and ball nose end geometries<br />

• Available in multiple lengths<br />

• Offered in inch, standard metric, and DIN metric sizes<br />

Applications<br />

• Use in general milling applications in cast iron, non-ferrous light metals, and plastics, as well as medium- to low-carbon steels.<br />

• Double-end mills offer an economical way to increase productivity.<br />

• Two-flute end mills are generally used for plunging, slotting, and heavy peripheral cuts.<br />

• Three-flute end mills provide a good compromise between the chip clearance of a two-flute end mill with the rigidity and wear resistance<br />

of a four-flute tool; they are especially suited for many slotting operations.<br />

• Four-flute end mills are most commonly used in profiling applications and harder materials than two-flute end mills. Stiffer construction<br />

results in minimal deflection. Four flutes provide good surface finishes and wear-resistant characteristics for excellent size control.<br />

• Feed and speed recommendations are listed on pages 12 and 13.<br />

Use Series CG end mills for finishing applications in these materials:<br />

Ductile (Nodular) and Malleable Cast Irons<br />

120-320 HB<br />

nodular/ductile, ferritic/pearlitic, pearlitic/martensitic<br />

ASTM A536, 60-40-18, 65-45-12, 80-55-06, 100-70-03<br />

SAE: J434, D4018, D4512, D5506, D7003<br />

Gray Cast Irons<br />

120-320 HB<br />

ASTM: A48, class 20, 25, 30, 35, 40, 45, 50, 55, 60<br />

SAE: J431: grade G1800, G3000, G3500, G4000<br />

Free-Machining and Low-Silicon Aluminum Alloys<br />

hypoeutectic 12.2% Si<br />

AA: A380, A390, A380-1, A390-1, A380-2, Duralcan<br />

Miscellaneous Non-ferrous Workpiece Materials —<br />

Non-ferrous machining alloys, copper, brass, zinc<br />

Low-Carbon Steel<br />

< 220 HB<br />

AISI: 1008, 1010, 1018, 1020, 1026, 10L18, 10L45, 10L50, 1108, 1117, 11L44, 1200 Series, 12L14<br />

Free-Machining Steels < 275 HB