2SP-10HG

2SP-10HG

2SP-10HG

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

FANUC-18iT / OSP-LGi<br />

4-Axis CNC Lathes<br />

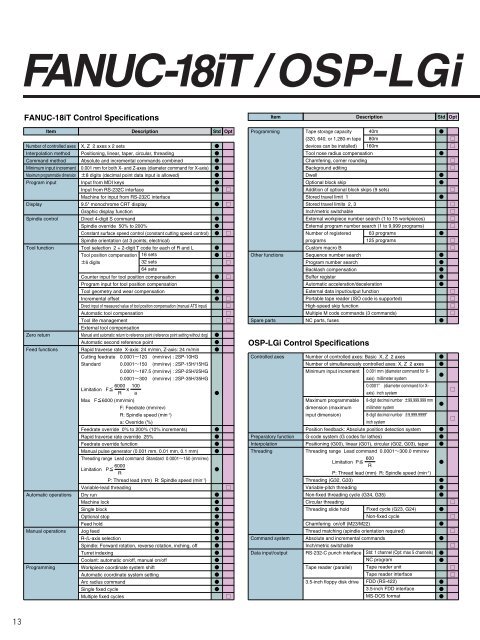

FANUC-18iT Control Specifications<br />

Item Description Std Opt Item Description Std Opt<br />

Item Description Std Opt<br />

Item Description Std Opt<br />

Number of controlled axes<br />

Interpolation method<br />

Command method<br />

Minimum input increment<br />

Maximum programmable dimension<br />

Program input<br />

X, Z 2 axes x 2 sets<br />

Positioning, linear, taper, circular, threading<br />

Absolute and incremental commands combined<br />

0.001 mm for both X- and Z-axes (diameter command for X-axis)<br />

8 digits (decimal point data input is allowed)<br />

Input from MDI keys<br />

<br />

<br />

<br />

<br />

<br />

<br />

Input from RS-232C interface<br />

<br />

Machine for input from RS-232C interface<br />

Display<br />

9.5" monochrome CRT display<br />

Graphic display function<br />

<br />

Spindle control Direct 4-digit S command<br />

Spindle override 50% to 200%<br />

<br />

<br />

Constant surface speed control (constant cutting speed control) <br />

Spindle orientation (at 3 points; electrical)<br />

Tool function<br />

Tool selection 2 + 2-digit T code for each of R and L<br />

Tool position compensation 16 sets<br />

<br />

<br />

6 digits<br />

32 sets<br />

<br />

64 sets<br />

Counter input for tool position compensation<br />

<br />

Program input for tool position compensation<br />

Tool geometry and wear compensation<br />

<br />

Incremental offset<br />

<br />

Direct input of measured value of tool position compensation (manual ATS input) <br />

Automatic tool compensation<br />

<br />

Tool life management<br />

<br />

External tool compensation<br />

Zero return<br />

Manual and automatic return to reference point (reference point setting without dog)<br />

Automatic second reference point<br />

<br />

<br />

Feed functions Rapid traverse rate X-axis: 24 m/min, Z-axis: 24 m/min <br />

Cutting feedrate 0.0001120 (mm/rev) : <strong>2SP</strong>-<strong>10HG</strong><br />

Standard 0.0001150 (mm/rev) : <strong>2SP</strong>-15H/15HG<br />

0.0001187.5 (mm/rev) : <strong>2SP</strong>-25H/25HG<br />

0.0001300 (mm/rev) : <strong>2SP</strong>-35H/35HG<br />

6000 100<br />

Limitation F<br />

R a<br />

<br />

Max F6000 (mm/min)<br />

F: Feedrate (mm/rev)<br />

R: Spindle speed (min -1 )<br />

a: Override (%)<br />

Feedrate override 0% to 200% (10% increments)<br />

<br />

Rapid traverse rate override 25%<br />

<br />

Feedrate override function<br />

<br />

Manual pulse generator (0.001 mm, 0.01 mm, 0.1 mm) <br />

Threading range Lead command Standard 0.0001150 (mm/rev)<br />

6000<br />

Limitation P<br />

R<br />

<br />

P: Thread lead (mm) R: Spindle speed (min -1 )<br />

Variable-lead threading<br />

<br />

Automatic operations Dry run<br />

Machine lock<br />

<br />

<br />

Single block<br />

<br />

Optional stop<br />

<br />

Feed hold<br />

<br />

Manual operations Jog feed<br />

R-/L-axis selection<br />

<br />

<br />

Spindle: Forward rotation, reverse rotation, inching, off <br />

Turret indexing<br />

<br />

Coolant: automatic on/off, manual on/off<br />

<br />

Programming<br />

Workpiece coordinate system shift<br />

<br />

Automatic coordinate system setting<br />

<br />

Arc radius command<br />

<br />

Single fixed cycle<br />

<br />

Multiple fixed cycles<br />

<br />

Programming<br />

Other functions<br />

Spare parts<br />

Tape storage capacity<br />

(320, 640, or 1,280-m tape<br />

devices can be installed)<br />

Tool nose radius compensation<br />

Chamfering, corner rounding<br />

Background editing<br />

Dwell<br />

Optional block skip<br />

Addition of optional block skips (9 sets)<br />

Stored travel limit 1<br />

Stored travel limits 2, 3<br />

Inch/metric switchable<br />

External workpiece number search (1 to 15 workpieces)<br />

External program number search (1 to 9,999 programs)<br />

Number of registered 63 programs<br />

programs<br />

125 programs<br />

Custom macro B<br />

Sequence number search<br />

Program number search<br />

Backlash compensation<br />

Buffer register<br />

Automatic acceleration/deceleration<br />

External data input/output function<br />

Portable tape reader (ISO code is supported)<br />

High-speed skip function<br />

Multiple M code commands (3 commands)<br />

NC parts, fuses<br />

OSP-LGi Control Specifications<br />

40m<br />

80m<br />

160m<br />

Controlled axes Number of controlled axes: Basic X, Z 2 axes<br />

Number of simultaneously controlled axes: X, Z 2 axes<br />

Minimum input increment 0.001 mm (diameter command for X-<br />

axis) millimeter system<br />

0.0001" (diameter command for X-<br />

axis) inch system<br />

Maximum programmable 8-digit decimal number 99,999.999 mm<br />

dimension (maximum millimeter system<br />

input dimension)<br />

8-digit decimal number 9,999.9999"<br />

inch system<br />

Position feedback: Absolute position detection system<br />

Preparatory function<br />

Interpolation<br />

Threading<br />

G-code system (G codes for lathes)<br />

Positioning (G00), linear (G01), circular (G02, G03), taper<br />

Threading range Lead command 0.0001300.0 mm/rev<br />

600<br />

Limitation P<br />

R<br />

P: Thread lead (mm) R: Spindle speed (min -1 )<br />

Threading (G32, G33)<br />

Variable-pitch threading<br />

Non-fixed threading cycle (G34, G35)<br />

Circular threading<br />

Threading slide hold Fixed cycle (G23, G24)<br />

Non-fixed cycle<br />

Chamfering on/off (M23/M22)<br />

Thread matching (spindle orientation required)<br />

Command system Absolute and incremental commands<br />

Inch/metric switchable<br />

Data input/output RS-232-C punch interface Std: 1 channel (Opt: max 5 channels)<br />

NC program<br />

Tape reader (parallel) Tape reader unit<br />

Tape reader interface<br />

3.5-inch floppy disk drive FDD (RS-422)<br />

3.5-inch FDD interface<br />

MS-DOS format<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

Display functions<br />

Spindle functions<br />

Tool functions<br />

Feed functions<br />

Automatic operation<br />

Manual operation<br />

Programming<br />

Thin color display (10.4" TFT)<br />

Multi-language display (selectable from 13 languages<br />

including Japanese, English, and German)<br />

Status display, alarm display, current position display, program<br />

display, single-block data display, clock function<br />

Parameter setting<br />

Load monitor<br />

NC operation monitor (time accumulation, 4 NC workpiece counters)<br />

Machining management function<br />

Guide map display (graphic display)<br />

Edit interlock<br />

Index-selected file handling function<br />

C-axis control<br />

Constant surface speed control (constant cutting speed control)<br />

Spindle override 50% to 200% (10% increments)<br />

Spindle orientation (at 1point; electrical)<br />

Digital communication<br />

Tool function: 4-digit T code or 6-digit T code<br />

Tool position compensation 32 sets<br />

64 sets<br />

96 sets<br />

Tool offset<br />

Auto tool compensation (direct input of measured value)<br />

Tool wear compensation<br />

Tool life management (12 sets)<br />

Tool nose radius compensation<br />

Rapid traverse rate 24 m/min for both X- and Z-axes<br />

Cutting feedrate 0.001187.5 mm/rev<br />

600 600<br />

Limitation F<br />

R <br />

F: Feedrate (mm/rev)<br />

R: Spindle speed (min -1 )<br />

: Override (%)<br />

Feedrate override 0% to 200% (10% increments)<br />

Rapid traverse rate override 25%<br />

Manual pulse generator (0.001, 0.01, 0.1 mm)<br />

Constant tangential speed control<br />

Feed per minute mm/min (G94)<br />

Feed per revolution mm/rev (G95)<br />

Automatic acceleration/deceleration<br />

Droop control (G64, G65)<br />

Dwell (G04)<br />

Single block, dry run<br />

Feed hold<br />

Machine lock<br />

Animated machining simulation (including cycle time calculation)<br />

Automatic operation, MDI operation<br />

Program selection<br />

Sequence number search<br />

Sequence return<br />

Manual interrupt/auto return<br />

Jog feed<br />

Spindle: Forward rotation, reverse rotation, inching, stop<br />

Turret indexing<br />

Coolantl: on, off, automatic<br />

Warming-up interface<br />

Pulse handle magnification<br />

Arc radius command<br />

Special fixed cycle (threading, grooving)<br />

Multitask machining - hole drilling cycles (drilling, tapping, boring)<br />

Auto programming (LAP4)<br />

Taper angle designation<br />

Auto arbitrary angle chamfering<br />

Block deletion<br />

Multitasking (programming)<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

Programming<br />

Multiple M code commands in the same block; max 3 commands<br />

Auxiliary function: M commands<br />

Communication buffer<br />

User task 1<br />

User task 2<br />

Input/output variables (16/16)<br />

Sub-programs, logical/functional<br />

calculations<br />

Program storage capacity 160 m<br />

320 m<br />

640 m<br />

1280 m<br />

2560 m<br />

Operation buffer capacity 160 m per spindle<br />

320 m per spindle<br />

640 m per spindle<br />

Scheduled program<br />

Automatic ISO/EIA determination<br />

TH/TV check<br />

Home position function (G20): positioning of 8 sets<br />

Synchronous wait function (P code, M code)<br />

Screen editor<br />

Diagnostic functions Self-diagnostics<br />

Machining management (trouble information)<br />

Axis control<br />

Profile generation<br />

Accuracy compensation Simplified pitch error compensation (2 points per axis)<br />

Pitch error compensation (120 points per axis)<br />

Backlash compensation<br />

Gauging,<br />

Workpiece gauging In-process gauging<br />

Skip functions<br />

Post-process gauging<br />

Tool tip gauging (touch setter) Automatic or manual<br />

Gauging data printout<br />

Safety functions Emergency stop<br />

NC operation panel lock<br />

Chuck barrier<br />

Status output<br />

Status output signal<br />

External data input/output External program selection<br />

Controller<br />

Programming method Ladder<br />

Mnemonic<br />

Function block<br />

Programmable controller PLC system class CLASS-A (5,000 steps)<br />

Function module function<br />

Coordinate functions Machine coordinate system<br />

Coordinate system setting: 1 set<br />

Zero point shift by G code (G50)<br />

Zero offset<br />

Multitask machining - coordinate conversion<br />

High-speed/highaccuracy<br />

functions AbsoScale detection<br />

Hi-G control<br />

0.0001 mm control<br />

Other functions Sequence number search<br />

Program number search<br />

Buffer register<br />

Backlash compensation<br />

Software travel limit<br />

Auto acceleration/deceleration<br />

Sequence return<br />

Manual interrupt/auto return<br />

Cycle time reduction<br />

Machine operation panel interface<br />

NC loader control (2 axes, 3 axes, 3-axis loader kit)<br />

Pulse generator (optical)<br />

Help function (explanation of G codes, M codes, and alarms)<br />

1,000 common variables<br />

Note: The OSP-LGU supports <strong>2SP</strong>-25H/HG and <strong>2SP</strong>-35H/HG machines.