K-Force OEM Replacement Belts - Magazooms

K-Force OEM Replacement Belts - Magazooms

K-Force OEM Replacement Belts - Magazooms

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

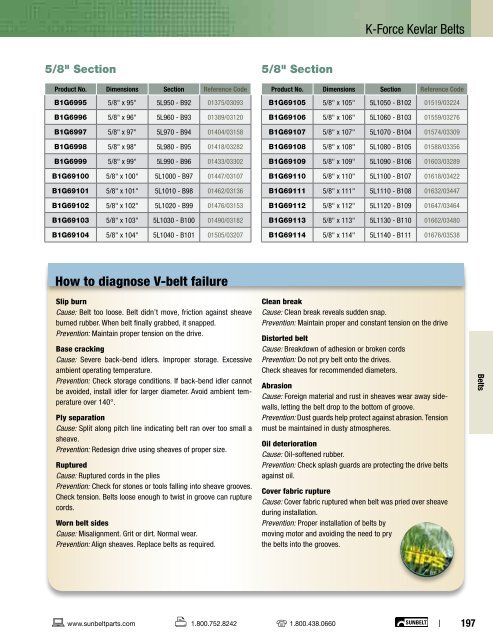

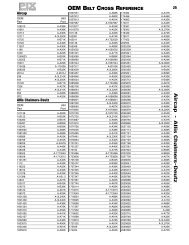

K-<strong>Force</strong> Kevlar <strong>Belts</strong><br />

5/8" Section<br />

Product No. Dimensions Section Reference Code<br />

B1G6995 5/8" x 95" 5L950 - B92 01375/03093<br />

B1G6996 5/8" x 96" 5L960 - B93 01389/03120<br />

B1G6997 5/8" x 97" 5L970 - B94 01404/03158<br />

B1G6998 5/8" x 98" 5L980 - B95 01418/03282<br />

B1G6999 5/8" x 99" 5L990 - B96 01433/03302<br />

B1G69100 5/8" x 100" 5L1000 - B97 01447/03107<br />

B1G69101 5/8" x 101" 5L1010 - B98 01462/03136<br />

B1G69102 5/8" x 102" 5L1020 - B99 01476/03153<br />

B1G69103 5/8" x 103" 5L1030 - B100 01490/03182<br />

B1G69104 5/8" x 104" 5L1040 - B101 01505/03207<br />

5/8" Section<br />

Product No. Dimensions Section Reference Code<br />

B1G69105 5/8" x 105" 5L1050 - B102 01519/03224<br />

B1G69106 5/8" x 106" 5L1060 - B103 01559/03276<br />

B1G69107 5/8" x 107" 5L1070 - B104 01574/03309<br />

B1G69108 5/8" x 108" 5L1080 - B105 01588/03356<br />

B1G69109 5/8" x 109" 5L1090 - B106 01603/03289<br />

B1G69110 5/8" x 110" 5L1100 - B107 01618/03422<br />

B1G69111 5/8" x 111" 5L1110 - B108 01632/03447<br />

B1G69112 5/8" x 112" 5L1120 - B109 01647/03464<br />

B1G69113 5/8" x 113" 5L1130 - B110 01662/03480<br />

B1G69114 5/8" x 114" 5L1140 - B111 01676/03538<br />

How to diagnose V-belt failure<br />

Slip burn<br />

Cause: Belt too loose. Belt didn’t move, friction against sheave<br />

burned rubber. When belt finally grabbed, it snapped.<br />

Prevention: Maintain proper tension on the drive.<br />

Base cracking<br />

Cause: Severe back-bend idlers. Improper storage. Excessive<br />

ambient operating temperature.<br />

Prevention: Check storage conditions. If back-bend idler cannot<br />

be avoided, install idler for larger diameter. Avoid ambient temperature<br />

over 140°.<br />

Ply separation<br />

Cause: Split along pitch line indicating belt ran over too small a<br />

sheave.<br />

Prevention: Redesign drive using sheaves of proper size.<br />

Ruptured<br />

Cause: Ruptured cords in the plies<br />

Prevention: Check for stones or tools falling into sheave grooves.<br />

Check tension. <strong>Belts</strong> loose enough to twist in groove can rupture<br />

cords.<br />

Worn belt sides<br />

Cause: Misalignment. Grit or dirt. Normal wear.<br />

Prevention: Align sheaves. Replace belts as required.<br />

Clean break<br />

Cause: Clean break reveals sudden snap.<br />

Prevention: Maintain proper and constant tension on the drive<br />

Distorted belt<br />

Cause: Breakdown of adhesion or broken cords<br />

Prevention: Do not pry belt onto the drives.<br />

Check sheaves for recommended diameters.<br />

Abrasion<br />

Cause: Foreign material and rust in sheaves wear away sidewalls,<br />

letting the belt drop to the bottom of groove.<br />

Prevention: Dust guards help protect against abrasion. Tension<br />

must be maintained in dusty atmospheres.<br />

Oil deterioration<br />

Cause: Oil-softened rubber.<br />

Prevention: Check splash guards are protecting the drive belts<br />

against oil.<br />

Cover fabric rupture<br />

Cause: Cover fabric ruptured when belt was pried over sheave<br />

during installation.<br />

Prevention: Proper installation of belts by<br />

moving motor and avoiding the need to pry<br />

the belts into the grooves.<br />

<strong>Belts</strong><br />

g www.sunbeltparts.com h 1.800.752.8242 y 1.800.438.0660 | 197