Mott Poruous Metal Filter Elements T - Teesing

Mott Poruous Metal Filter Elements T - Teesing

Mott Poruous Metal Filter Elements T - Teesing

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

A general overview of <strong>Mott</strong> precision<br />

sintered porous metal filter elements.<br />

Introduction.<br />

<strong>Mott</strong> Corporation manufactures standard filter elements in<br />

a broad range of materials and sizes, and with a selection<br />

of fittings, so they can be easily specified with the characteristics<br />

and configurations customers require. <strong>Mott</strong> can<br />

incorporate custom features or create completely original<br />

designs for specialized needs.<br />

High differential pressure capability – <strong>Mott</strong> porous<br />

metal filter elements can be designed to withstand differential<br />

pressures over 3000 psi.<br />

Cleanable filter elements – As part of permanent<br />

filtration installations, <strong>Mott</strong> elements can be effectively<br />

cleaned in situ in many applications. This is accomplished<br />

by a blowback system for gaseous applications or a backwash/backflush<br />

system for liquid applications. <strong>Mott</strong><br />

engineers are highly experienced in designing and constructing<br />

such systems. Examples of these process filters<br />

are the LSI filters for liquid/solids applications and the GSV<br />

filter for gas/solids applications.<br />

Contaminants can also be removed chemically by<br />

means of solvents, caustic wash, acid wash, as well as<br />

water, steam and air flush. Ultrasonic cleaning is used to<br />

remove chemically inert materials. Controlled-atmosphere<br />

fluid bed furnaces may also be used.<br />

<strong>Mott</strong> precision porous metal filter elements may be<br />

cleaned and subsequently kept in continuous operation<br />

for years, where other types of elements would have to<br />

be replaced several times.<br />

High corrosion resistance – While 316L stainless steel<br />

is the standard material of construction, <strong>Mott</strong> elements are<br />

available in a variety of materials for chemical compatibility<br />

with many liquids and gases. Other materials include:<br />

304L, 310, 347 and 430 stainless steel; Hastelloy ® B,<br />

B-2, C-22, C276, N and X; Inconel ® 600, 625 and 690;<br />

Monel ® 400, Nickel 200, Alloy 20 and titanium.<br />

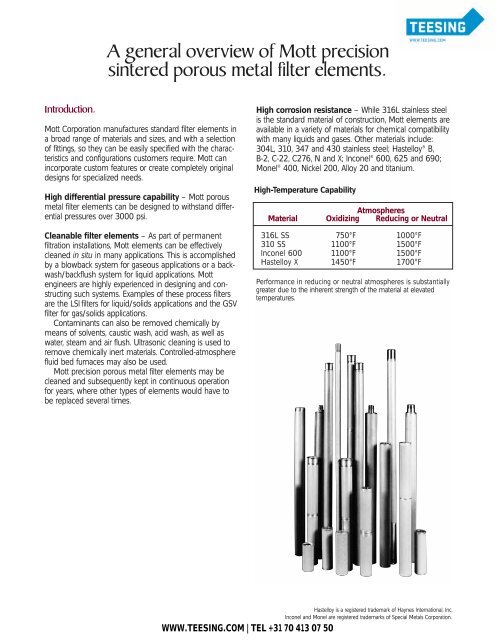

High-Temperature Capability<br />

Atmospheres<br />

Material Oxidizing Reducing or Neutral<br />

316L SS 750°F 1000°F<br />

310 SS 1100°F 1500°F<br />

Inconel 600 1100°F 1500°F<br />

Hastelloy X 1450°F 1700°F<br />

Performance in reducing or neutral atmospheres is substantially<br />

greater due to the inherent strength of the material at elevated<br />

temperatures.<br />

WWW.TEESING.COM | TEL +31 70 413 07 50<br />

Hastelloy is a registered trademark of Haynes International, Inc.<br />

Inconel and Monel are registered trademarks of Special <strong>Metal</strong>s Corporation.