THE CATALYST REVIEW - The Catalyst Group

THE CATALYST REVIEW - The Catalyst Group

THE CATALYST REVIEW - The Catalyst Group

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

EXPERIMENTAL<br />

Next-Generation Catalysis for Renewables: Combining Enzymatic with<br />

Inorganic Heterogeneous Catalysis for Bulk Chemical Production...<br />

<strong>The</strong> conversion of biomass necessitates the development of a new generation of catalysts that enable new kinds of reactions,<br />

processes, and conditions than those conventionally employed. Both enzymatic catalysis (biocatalysis) and heterogeneous inorganic<br />

catalysis are likely to play a major role and, potentially, be combined. One type of combination involves one-pot cascade catalysis<br />

with active sites from bio and inorganic catalysts as key components in the development of a biorefinery - a facility that integrates a<br />

number of processes in biomass conversion to produce fuels, power, and chemicals.<br />

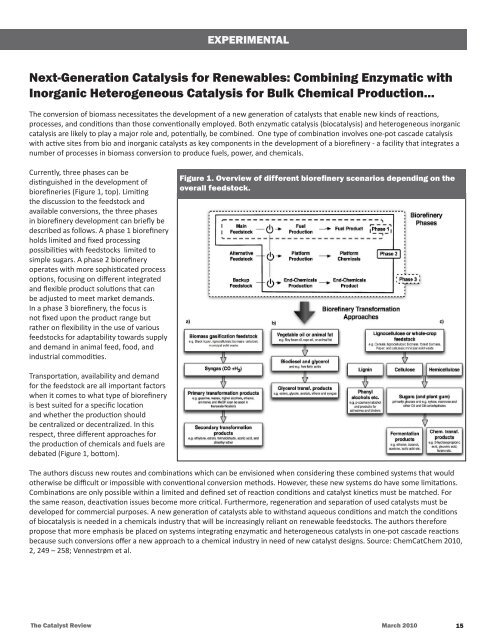

Currently, three phases can be<br />

distinguished in the development of<br />

biorefineries (Figure 1, top). Limiting<br />

the discussion to the feedstock and<br />

available conversions, the three phases<br />

in biorefinery development can briefly be<br />

described as follows. A phase 1 biorefinery<br />

holds limited and fixed processing<br />

possibilities with feedstocks limited to<br />

simple sugars. A phase 2 biorefinery<br />

operates with more sophisticated process<br />

options, focusing on different integrated<br />

and flexible product solutions that can<br />

be adjusted to meet market demands.<br />

In a phase 3 biorefinery, the focus is<br />

not fixed upon the product range but<br />

rather on flexibility in the use of various<br />

feedstocks for adaptability towards supply<br />

and demand in animal feed, food, and<br />

industrial commodities.<br />

Figure 1. Overview of different biorefinery scenarios depending on the<br />

overall feedstock.<br />

Transportation, availability and demand<br />

for the feedstock are all important factors<br />

when it comes to what type of biorefinery<br />

is best suited for a specific location<br />

and whether the production should<br />

be centralized or decentralized. In this<br />

respect, three different approaches for<br />

the production of chemicals and fuels are<br />

debated (Figure 1, bottom).<br />

<strong>The</strong> authors discuss new routes and combinations which can be envisioned when considering these combined systems that would<br />

otherwise be difficult or impossible with conventional conversion methods. However, these new systems do have some limitations.<br />

Combinations are only possible within a limited and defined set of reaction conditions and catalyst kinetics must be matched. For<br />

the same reason, deactivation issues become more critical. Furthermore, regeneration and separation of used catalysts must be<br />

developed for commercial purposes. A new generation of catalysts able to withstand aqueous conditions and match the conditions<br />

of biocatalysis is needed in a chemicals industry that will be increasingly reliant on renewable feedstocks. <strong>The</strong> authors therefore<br />

propose that more emphasis be placed on systems integrating enzymatic and heterogeneous catalysts in one-pot cascade reactions<br />

because such conversions offer a new approach to a chemical industry in need of new catalyst designs. Source: ChemCatChem 2010,<br />

2, 249 – 258; Vennestrøm et al.<br />

<strong>The</strong> <strong>Catalyst</strong> Review March 2010<br />

15