Issue 15 Spring 2013 - National Rural Network

Issue 15 Spring 2013 - National Rural Network

Issue 15 Spring 2013 - National Rural Network

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Anaerobic Digestion on Limerick Farm<br />

Farm-based anaerobic digestion is in its infancy in Ireland<br />

with less than a handful of plants. In Germany, the world<br />

leader, there are around 4,000 on-farm anaerobic digesters.<br />

There are less than 100 in the UK, with ambitious plans to<br />

increase to 1,000 by 2020.<br />

The McDonnell family, who farm outside Shanagolden in<br />

Co. Limerick, have installed one of the most advanced<br />

anaerobic digestion (AD) on-farm plants in the country.<br />

GreenGas AD is the only plant in Ireland currently selling<br />

electricity into the national grid.<br />

Brothers David and Richard McDonnell run a 300-cow dairy<br />

herd, supplying Kerry Group. They also run a free-range<br />

poultry enterprise, supplying chickens to Shannon Vale<br />

Foods in Clonakilty. A few years ago, they started looking at<br />

alternative energy and David visited a number of AD plants<br />

in Germany and Denmark.<br />

He engaged German company Krieg and Fischer, which<br />

has built over <strong>15</strong>0 AD plants worldwide, to design the plant.<br />

Construction was completed in 2010 and GreenGas AD<br />

went into commercial operation in early 2011.<br />

Management<br />

“It is a highly complex chemical, biological, mechanical<br />

and electrical process which requires management on a<br />

daily basis. It was a heavy investment and it would not be<br />

viable without grant-aid. We are meeting our financial targets<br />

and hope to have the investment re-paid within about eight<br />

years,” said David.<br />

As well as the AD plant, the McDonnells also installed two<br />

2.3MW wind turbines on their farm, which were connected<br />

to the national grid in late 2010. “We had the finance<br />

arranged before the collapse in 2008 otherwise we would<br />

probably never have been able to go ahead,” said David.<br />

Each turbine is potentially 10 times more powerful,<br />

depending on wind speeds, in terms of electricity generation<br />

than the AD plant. Last year, the two turbines delivered over<br />

12 times more electricity to the grid than the AD plant. All<br />

in all, the two alternative energy ventures must make the<br />

McDonnell farm among the most carbon efficient in the<br />

country.<br />

Electricity<br />

All animal slurry and litter from the poultry enterprise is<br />

used as feedstock for biogas production. Waste fruit and<br />

vegetables and waste from hatcheries are also sourced from<br />

around the locality. The biogas produced in the anaerobic<br />

digestion process is used as fuel in a combined heat and<br />

power (CHP) engine.<br />

The resultant electricity produced is sold to the national<br />

grid and the heat generated is recycled for heating in<br />

both the AD plant and the poultry enterprise. The electricity<br />

generated by the plant is the equivalent of the total annual<br />

consumption of around <strong>15</strong>0 homes.<br />

The by-product from the plant is used as fertiliser on the<br />

McDonnell and other farms in the locality. It has significant<br />

economic and environmental benefits, with better availability<br />

of nutrients and reduced odours.<br />

The ambitious project is the culmination of painstaking<br />

research and negotiation through very detailed regulatory<br />

requirements during the planning and plant set-up stages. It<br />

is an expensive and high tech operation.<br />

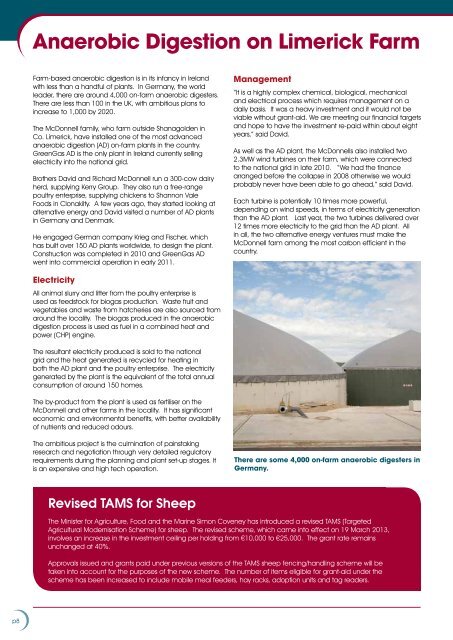

There are some 4,000 on-farm anaerobic digesters in<br />

Germany.<br />

Revised TAMS for Sheep<br />

The Minister for Agriculture, Food and the Marine Simon Coveney has introduced a revised TAMS (Targeted<br />

Agricultural Modernisation Scheme) for sheep. The revised scheme, which came into effect on 19 March <strong>2013</strong>,<br />

involves an increase in the investment ceiling per holding from €10,000 to €25,000. The grant rate remains<br />

unchanged at 40%.<br />

Approvals issued and grants paid under previous versions of the TAMS sheep fencing/handling scheme will be<br />

taken into account for the purposes of the new scheme. The number of items eligible for grant-aid under the<br />

scheme has been increased to include mobile meal feeders, hay racks, adoption units and tag readers.<br />

p8