Guidelines for Rolling in Cricket - Ecb - England and Wales Cricket ...

Guidelines for Rolling in Cricket - Ecb - England and Wales Cricket ...

Guidelines for Rolling in Cricket - Ecb - England and Wales Cricket ...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Centre <strong>for</strong> Sports Surface Technology<br />

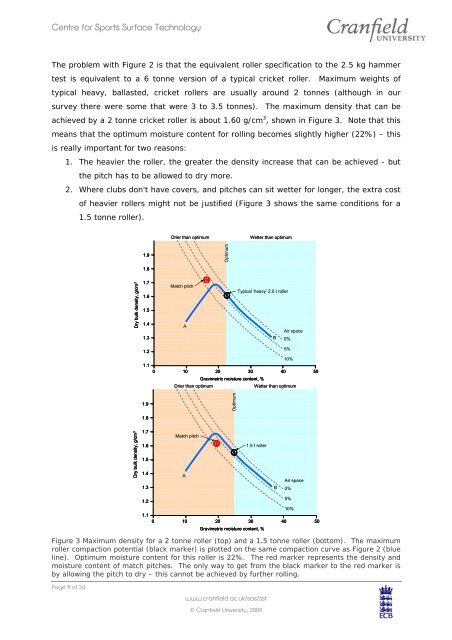

The problem with Figure 2 is that the equivalent roller specification to the 2.5 kg hammer<br />

test is equivalent to a 6 tonne version of a typical cricket roller. Maximum weights of<br />

typical heavy, ballasted, cricket rollers are usually around 2 tonnes (although <strong>in</strong> our<br />

survey there were some that were 3 to 3.5 tonnes). The maximum density that can be<br />

achieved by a 2 tonne cricket roller is about 1.60 g/cm 3 , shown <strong>in</strong> Figure 3. Note that this<br />

means that the optimum moisture content <strong>for</strong> roll<strong>in</strong>g becomes slightly higher (22%) – this<br />

is really important <strong>for</strong> two reasons:<br />

1. The heavier the roller, the greater the density <strong>in</strong>crease that can be achieved - but<br />

the pitch has to be allowed to dry more.<br />

2. Where clubs don't have covers, <strong>and</strong> pitches can sit wetter <strong>for</strong> longer, the extra cost<br />

of heavier rollers might not be justified (Figure 3 shows the same conditions <strong>for</strong> a<br />

1.5 tonne roller).<br />

Drier than optimum<br />

Wetter than optimum<br />

1.9<br />

Optimum<br />

1.8<br />

Dry bulk density, g/cm 3<br />

1.7<br />

1.6<br />

1.5<br />

1.4<br />

1.3<br />

Match pitch<br />

A<br />

Typical ‘heavy’ 2.0 t roller<br />

Air space<br />

B<br />

0%<br />

1.2<br />

1.1<br />

5%<br />

10%<br />

0 10 20 30 40 50<br />

Gravimetric moisture content, %<br />

Drier than optimum<br />

Wetter than optimum<br />

1.9<br />

Optimum<br />

1.8<br />

Dry bulk density, g/cm 3<br />

1.7<br />

1.6<br />

1.5<br />

1.4<br />

1.3<br />

Match pitch<br />

A<br />

1.5 t roller<br />

B<br />

Air space<br />

0%<br />

1.2<br />

1.1<br />

5%<br />

10%<br />

0 10 20 30 40 50<br />

Gravimetric moisture content, %<br />

Figure 3 Maximum density <strong>for</strong> a 2 tonne roller (top) <strong>and</strong> a 1.5 tonne roller (bottom). The maximum<br />

roller compaction potential (black marker) is plotted on the same compaction curve as Figure 2 (blue<br />

l<strong>in</strong>e). Optimum moisture content <strong>for</strong> this roller is 22%. The red marker represents the density <strong>and</strong><br />

moisture content of match pitches. The only way to get from the black marker to the red marker is<br />

by allow<strong>in</strong>g the pitch to dry – this cannot be achieved by further roll<strong>in</strong>g.<br />

Page 9 of 34<br />

www.cranfield.ac.uk/sas/sst<br />

© Cranfield University, 2009

![Indoor Sports Halls with Cricket Provision [TS3] - Ecb - England and ...](https://img.yumpu.com/49070696/1/190x135/indoor-sports-halls-with-cricket-provision-ts3-ecb-england-and-.jpg?quality=85)