download - OATG. Oxford Asian Textile Group

download - OATG. Oxford Asian Textile Group

download - OATG. Oxford Asian Textile Group

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

SINDHI AJRAKS<br />

10<br />

eral days. The treatment is alternated<br />

and there are several steps involved in<br />

it. By the end, the oil is completely<br />

impregnated into the fibre. This is<br />

what gives the suppleness to the Ajrak<br />

as well as making it virtually indestructible.<br />

The next stage prepares the fabric<br />

for the printing. Gurrh (molasses),<br />

dried lemons, castor oil, Sakun<br />

(tamarisk) and water are used to make<br />

dough. This dough is mixed in a big<br />

vessel with water and the cloth is<br />

soaked in it.<br />

Printing<br />

1.Gum and lime is mixed with alizarine<br />

for Kiryana (printing of the white<br />

outlines). Blocks are soaked in the solution<br />

(brown) and the white outlines<br />

are printed over. This will be washed<br />

later to give the white outlines.<br />

2. Kut: Printing of the black areas:<br />

This uses gum, iron sulphate, Fullers<br />

earth and water to make the black outlines.<br />

3. The fabric on which Kut and Kiryana<br />

have been printed are now reprinted<br />

with the Kiryana mixture. This<br />

ensures that when the cloth is soaked<br />

in dye these areas will remain sparkling<br />

white or black and the colour<br />

will not dye these areas.<br />

4. The next step is printing over the<br />

red areas. Amongst the ingredients<br />

used is Ata (wheat flour), Phitkari<br />

(alum), Gurrh (molasses) and Saunf<br />

(fennel). The areas to be dyed red are<br />

printed and while still wet are dusted<br />

with ground cow dung or rice husk to<br />

protect against the indigo dye to be<br />

printed later.<br />

5. Indigo, Chuna (lime), soda and<br />

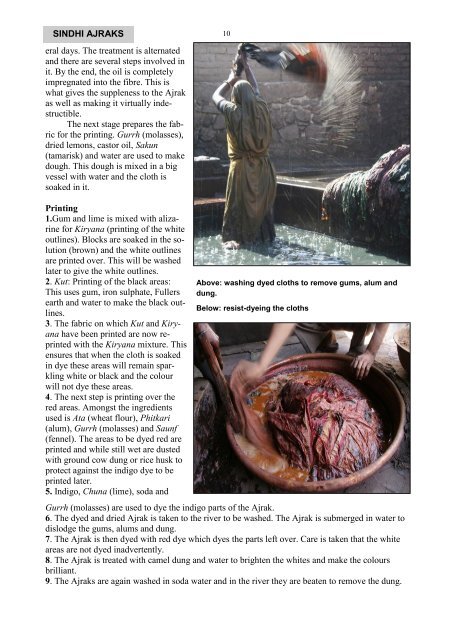

Above: washing dyed cloths to remove gums, alum and<br />

dung.<br />

Below: resist-dyeing the cloths<br />

Gurrh (molasses) are used to dye the indigo parts of the Ajrak.<br />

6. The dyed and dried Ajrak is taken to the river to be washed. The Ajrak is submerged in water to<br />

dislodge the gums, alums and dung.<br />

7. The Ajrak is then dyed with red dye which dyes the parts left over. Care is taken that the white<br />

areas are not dyed inadvertently.<br />

8. The Ajrak is treated with camel dung and water to brighten the whites and make the colours<br />

brilliant.<br />

9. The Ajraks are again washed in soda water and in the river they are beaten to remove the dung.