ROBO-8779VG2AR Intel® CoreTM 2 Quad processor ... - IPC2U

ROBO-8779VG2AR Intel® CoreTM 2 Quad processor ... - IPC2U

ROBO-8779VG2AR Intel® CoreTM 2 Quad processor ... - IPC2U

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

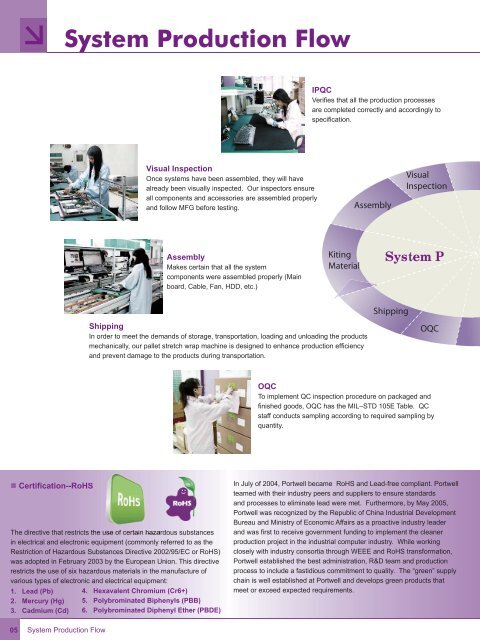

System Production Flow<br />

IPQC<br />

<br />

are completed correctly and accordingly to<br />

<br />

Visual Inspection<br />

Once systems have been assembled, they will have<br />

already been visually inspected. Our inspectors ensure<br />

all components and accessories are assembled properly<br />

and follow MFG before testing.<br />

Assembly<br />

Visual<br />

Inspection<br />

Assembly<br />

Makes certain that all the system<br />

components were assembled properly (Main<br />

board, Cable, Fan, HDD, etc.)<br />

Kiting<br />

Material<br />

System P<br />

Shipping<br />

Shipping<br />

In order to meet the demands of storage, transportation, loading and unloading the products<br />

<br />

and prevent damage to the products during transportation.<br />

OQC<br />

OQC<br />

To implement QC inspection procedure on packaged and<br />

<br />

staff conducts sampling according to required sampling by<br />

quantity.<br />

• <br />

The directive that restricts the use of certain hazardous substances<br />

in electrical and electronic equipment (commonly referred to as the<br />

Restriction of Hazardous Substances Directive 2002/95/EC or RoHS)<br />

was adopted in February 2003 by the European Union. This directive<br />

restricts the use of six hazardous materials in the manufacture of<br />

various types of electronic and electrical equipment:<br />

1. Lead (Pb)<br />

2. Mercury (Hg)<br />

3. Cadmium (Cd)<br />

4. Hexavalent Chromium (Cr6+)<br />

5. Polybrominated Biphenyls (PBB)<br />

6. Polybrominated Diphenyl Ether (PBDE)<br />

<br />

teamed with their industry peers and suppliers to ensure standards<br />

and processes to eliminate lead were met. Furthermore, by May 2005,<br />

Portwell was recognized by the Republic of China Industrial Development<br />

Bureau and Ministry of Economic Affairs as a proactive industry leader<br />

<br />

production project in the industrial computer industry. While working<br />

closely with industry consortia through WEEE and RoHS transformation,<br />

Portwell established the best administration, R&D team and production<br />

process to include a fastidious commitment to quality. The “green” supply<br />

chain is well established at Portwell and develops green products that<br />

meet or exceed expected requirements.<br />

05<br />

System Production Flow