Fall 2009 - Florida Tech Today - Florida Institute of Technology

Fall 2009 - Florida Tech Today - Florida Institute of Technology

Fall 2009 - Florida Tech Today - Florida Institute of Technology

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Continued from page 35<br />

With an estimated 4 percent <strong>of</strong> the world’s<br />

greenhouse gases emanating from ships, a more efficient<br />

fleet contributes to a greener planet.<br />

<strong>Today</strong>, many ships use biocide-free silicone fouling<br />

release coatings, which Swain’s group has helped<br />

to develop. These coatings work much like a sticky<br />

stamp that is attached to a backing paper, yet easily<br />

peeled away. With silicone coatings, marine growth<br />

can attach to the hull but is easily removed.<br />

This has paved the way for another facet <strong>of</strong><br />

Swain’s research—the concept <strong>of</strong> hull grooming.<br />

“One <strong>of</strong> the most exciting projects we’re involved<br />

with at the moment is a fully autonomous underwater<br />

grooming device,” says Swain. Designed and<br />

developed by SeaRobotics Corp. and ONR, the Hull<br />

BUG (Bioinspired Underwater Grooming) is a marine<br />

maintenance vehicle that operates much like a pool<br />

cleaner or robotic vacuum. The machine suctions to<br />

the hull <strong>of</strong> a ship at port and goes to work removing<br />

marine growth before it builds up and requires costly<br />

and extensive cleaning. It’s a proactive approach to<br />

36<br />

bi<strong>of</strong>ouling prevention and a technology the team is<br />

eager to introduce to the shipping industry.<br />

Contributing to solutions that make a positive<br />

impact is at the heart <strong>of</strong> Swain’s work, as is interacting<br />

with his students.<br />

“I enjoy this group because I know we contribute<br />

to improving antifouling technology and that<br />

will make shipping and marine industries more efficient<br />

and therefore more environmentally friendly.<br />

The students do excellent work, and I am fortunate<br />

because I interact with a fun group <strong>of</strong> people who are<br />

motivated to find solutions, and that is a good feeling.”<br />

Christena Callahan<br />

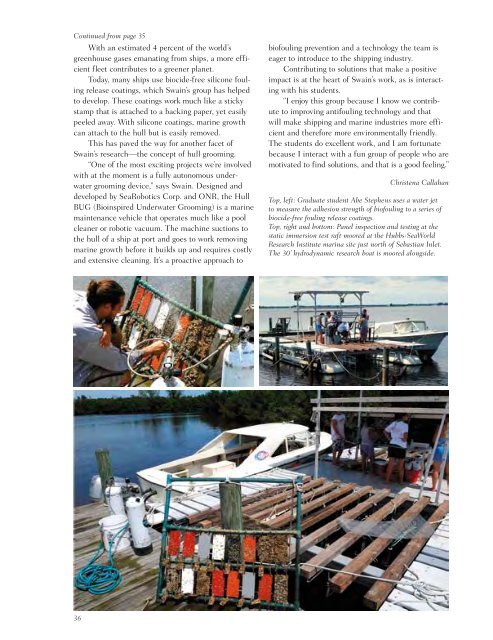

Top, left: Graduate student Abe Stephens uses a water jet<br />

to measure the adhesion strength <strong>of</strong> bi<strong>of</strong>ouling to a series <strong>of</strong><br />

biocide-free fouling release coatings.<br />

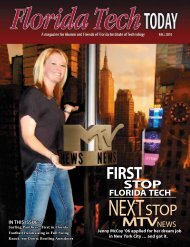

Top, right and bottom: Panel inspection and testing at the<br />

static immersion test raft moored at the Hubbs-SeaWorld<br />

Research <strong>Institute</strong> marina site just north <strong>of</strong> Sebastian Inlet.<br />

The 30’ hydrodynamic research boat is moored alongside.